Home / Building Structures & Components / Page 4

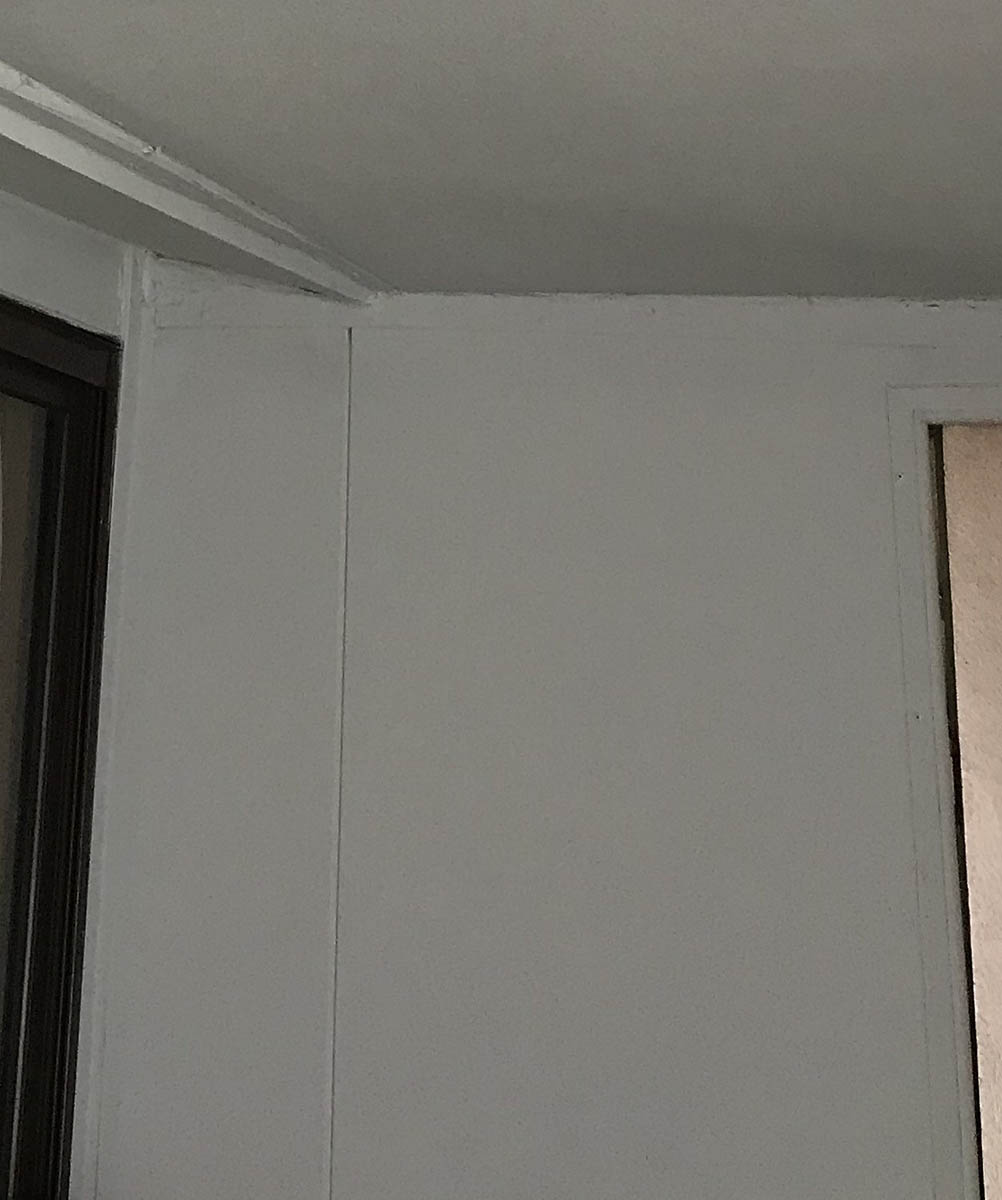

Asbestos cement architraves and window components

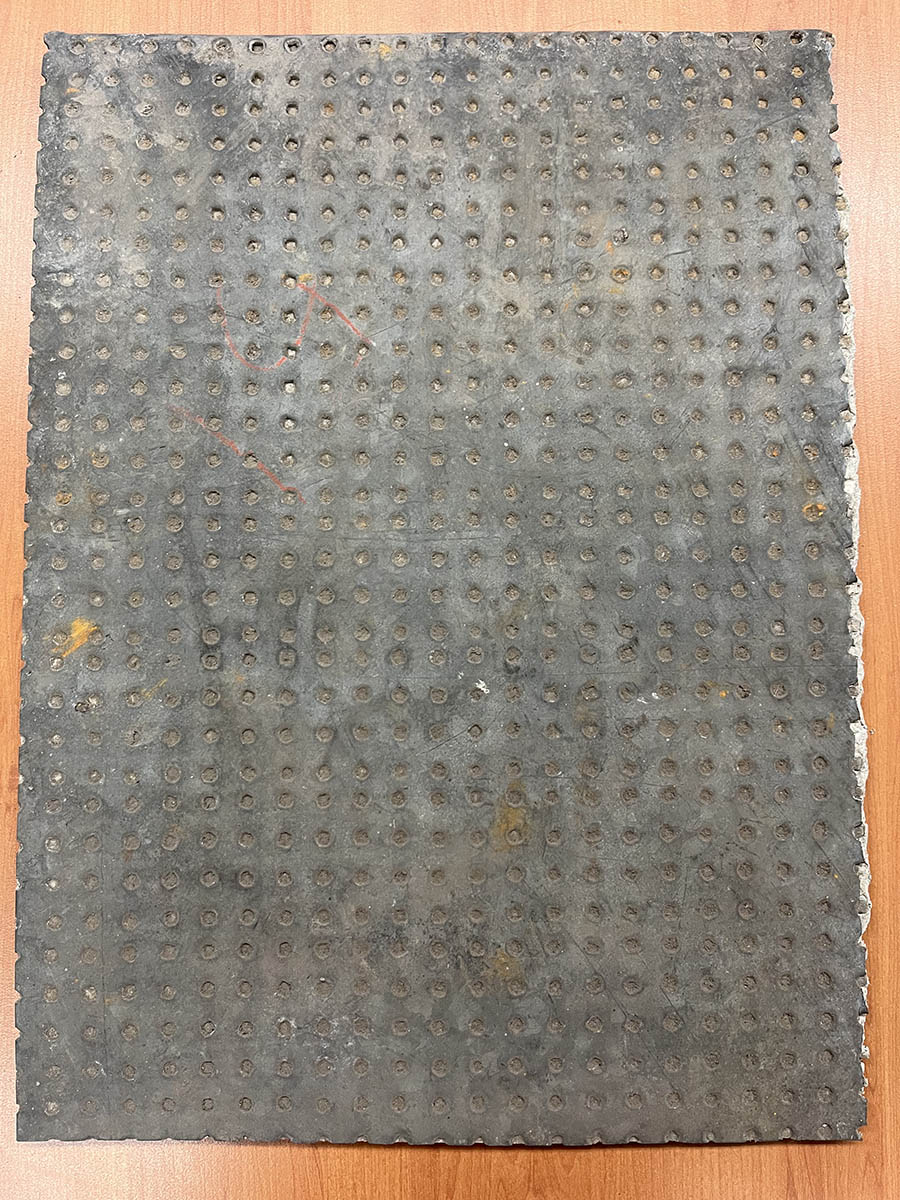

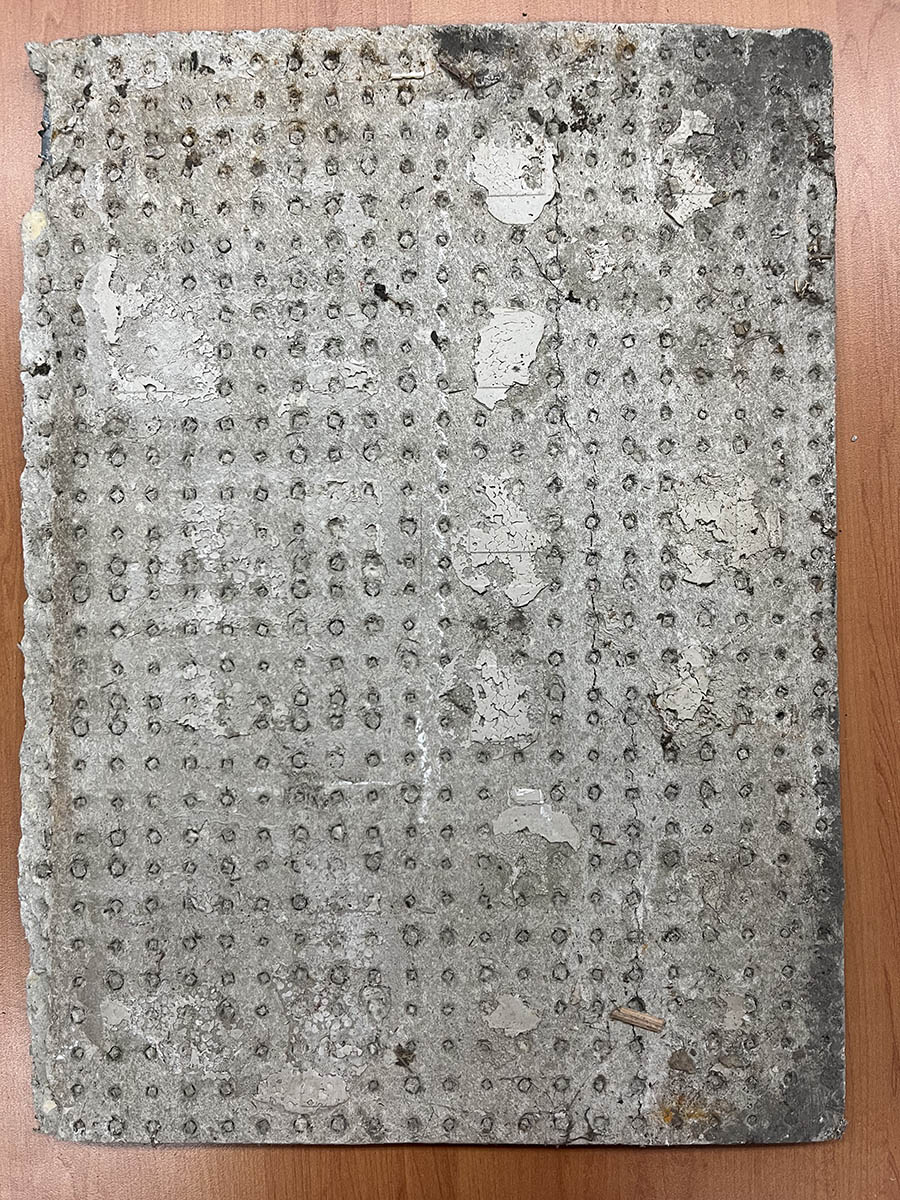

Description

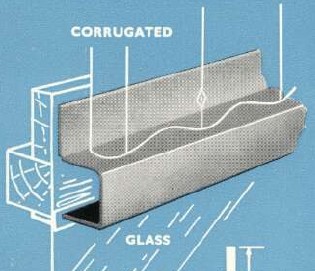

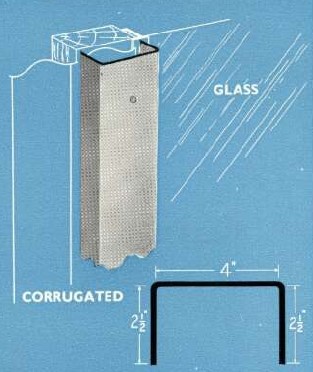

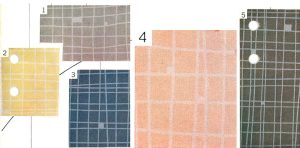

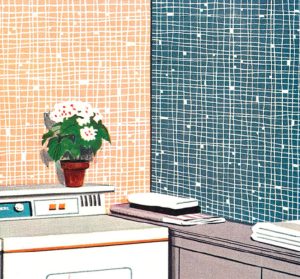

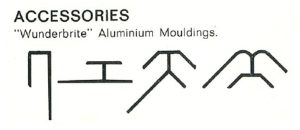

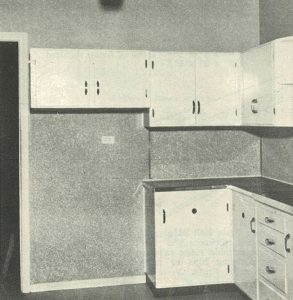

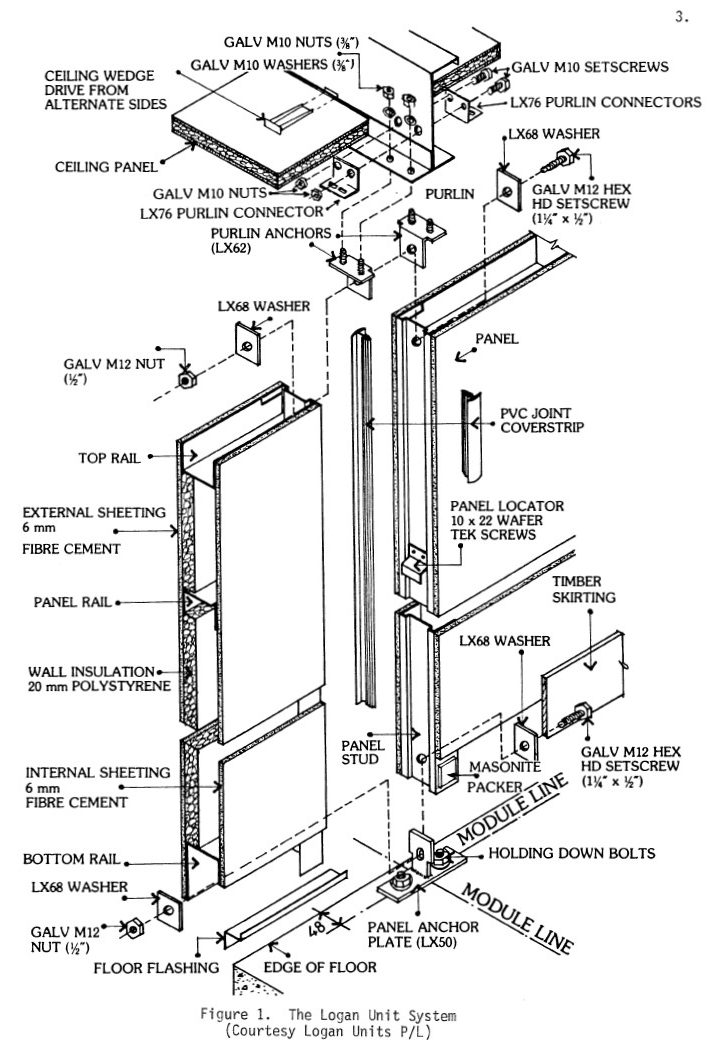

Moulded AC fittings for around windows and architraves (interior and exterior) to allow structured fit with AC corrugated sheeting used for walls. Mainly designed for exterior.

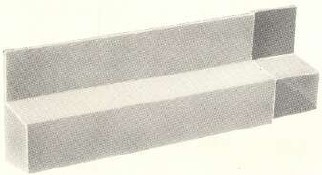

- Door and window head

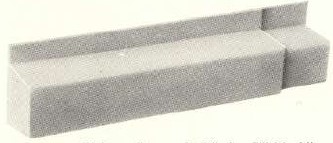

- Windowsill

- Vertical window stile

- Windowsill stop-end – spigoted

- Door and window head stop-end – spigoted

Jointing coverstrips were also used for this function.

Spigoted sections and stop-ends produced.

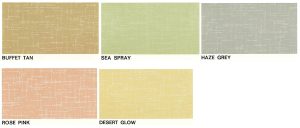

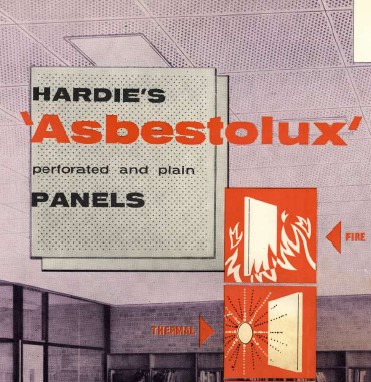

Brands/products

- Fibrolite

- Asbestolite

- Durabestos

- Tasbestos

Years of production/use

Prior to 1990

Residential uses

Houses, garages, sheds

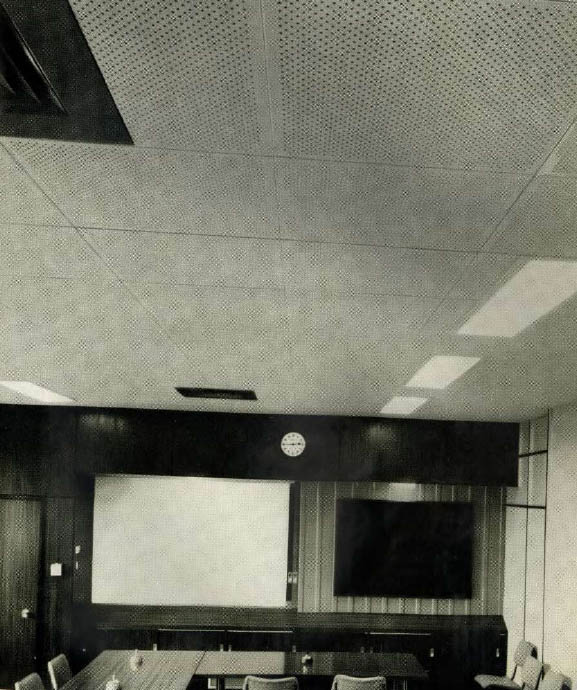

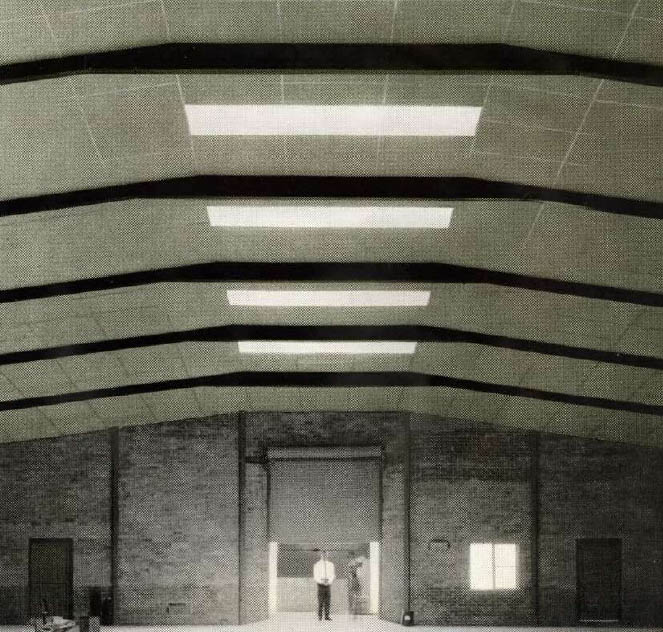

Industrial uses

Offices, community and government buildings and all industrial building applications

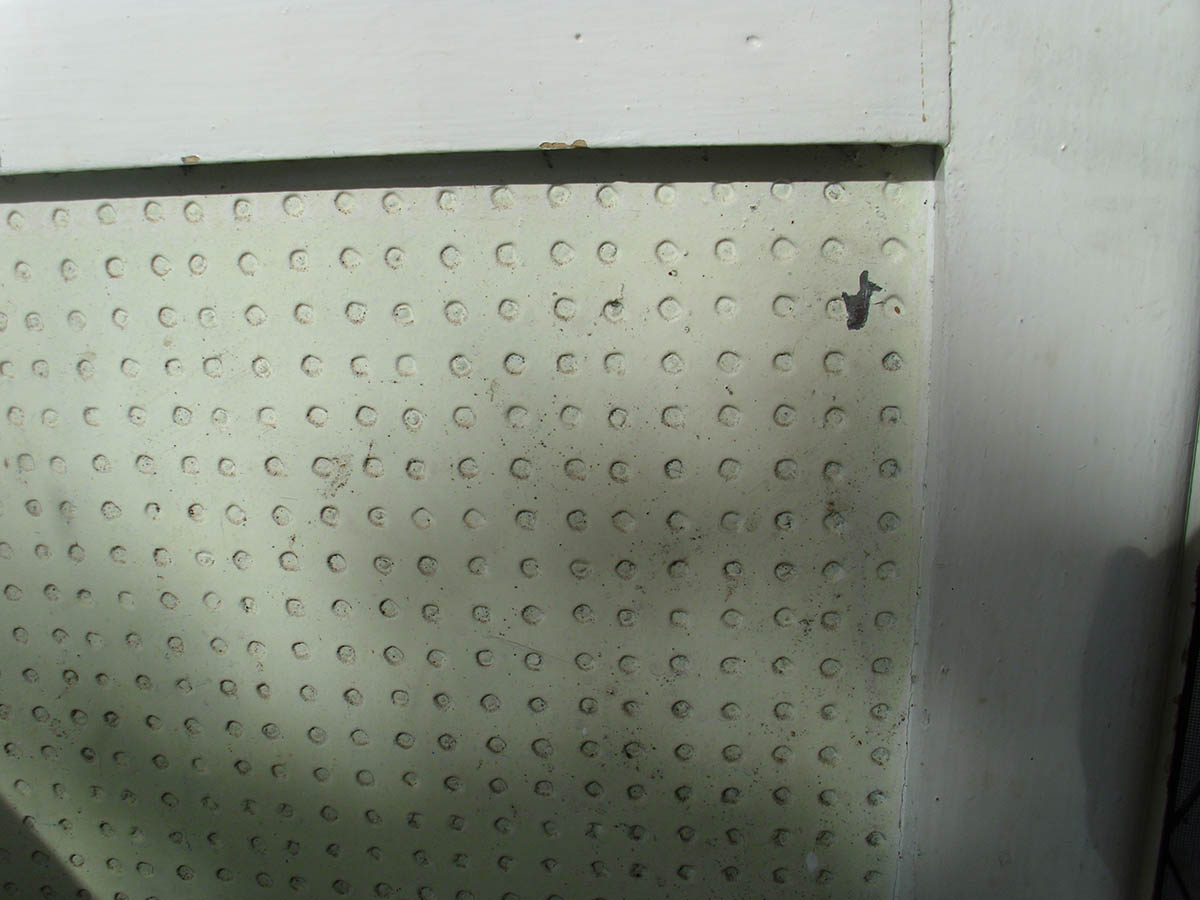

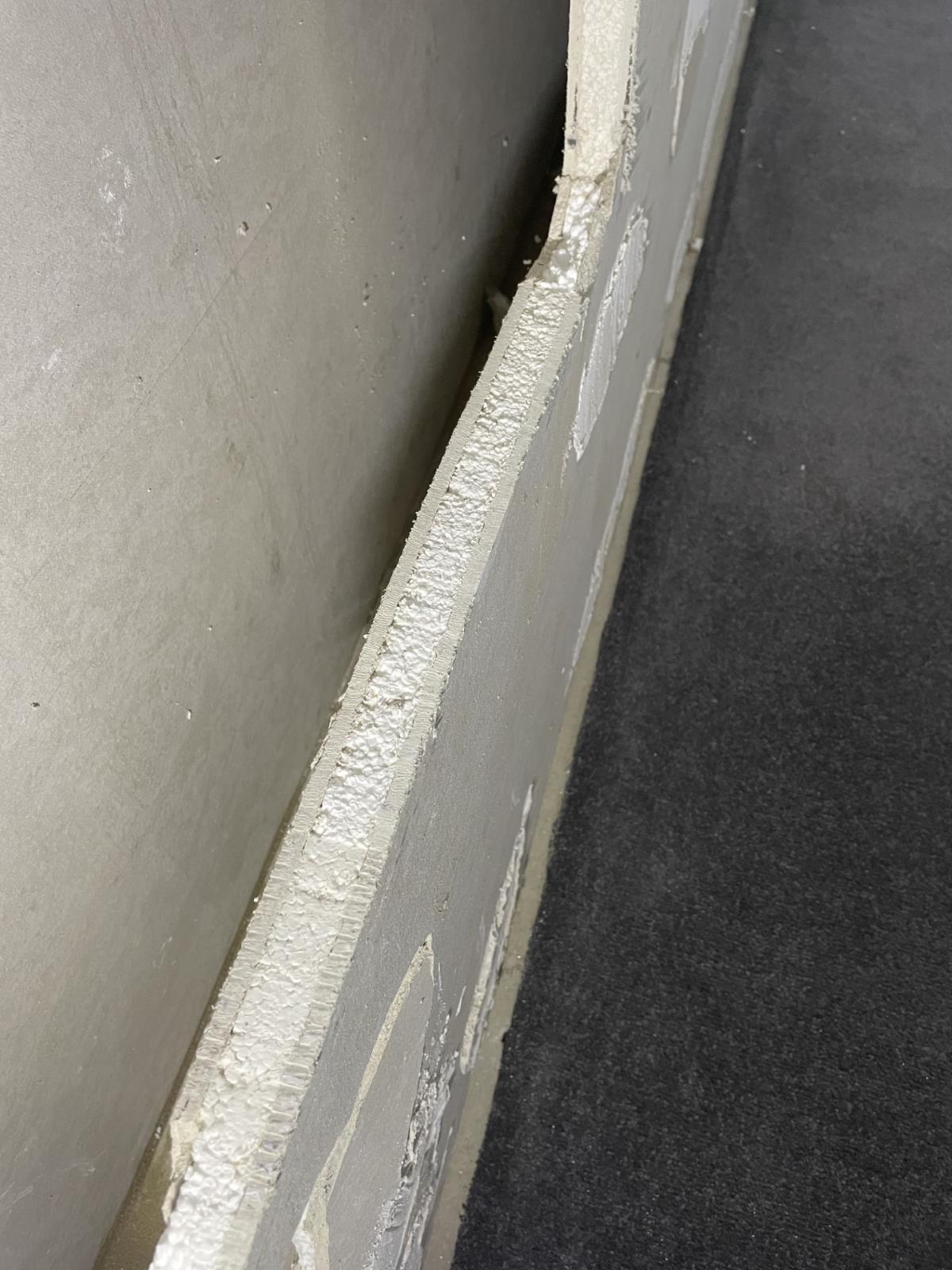

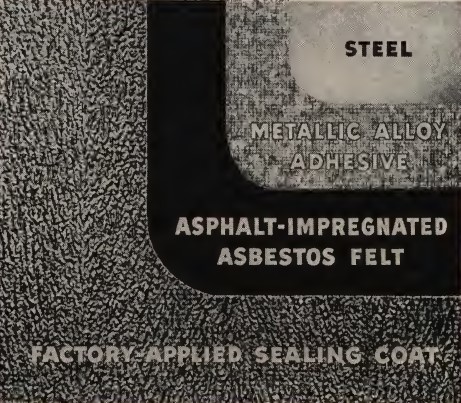

Be aware

Damaged or weathered product may have exposed fibres or be easily crumbled.

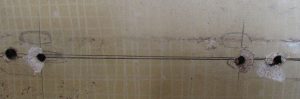

Bituminous felt washers were often used with the screws for fixing.

Hardie’s 1961 instructions:

For 1 and 2 – Fixings: 4” roofing screws or 4” roofing bolts, together with round galvanised iron washers and bituminous felt washers, fixed through moulding into window girt.

For 3, 4 and 5 – Fixings: 3½” roofing screws or 3½” roofing bolts, together with round galvanised iron washers and bituminous felt washers, fixed through moulding into window trimmers.