Home / Building structures & components / Roofing / Corrugated asbestos cement sheeting – roofing

Corrugated asbestos cement sheeting – roofing

Description

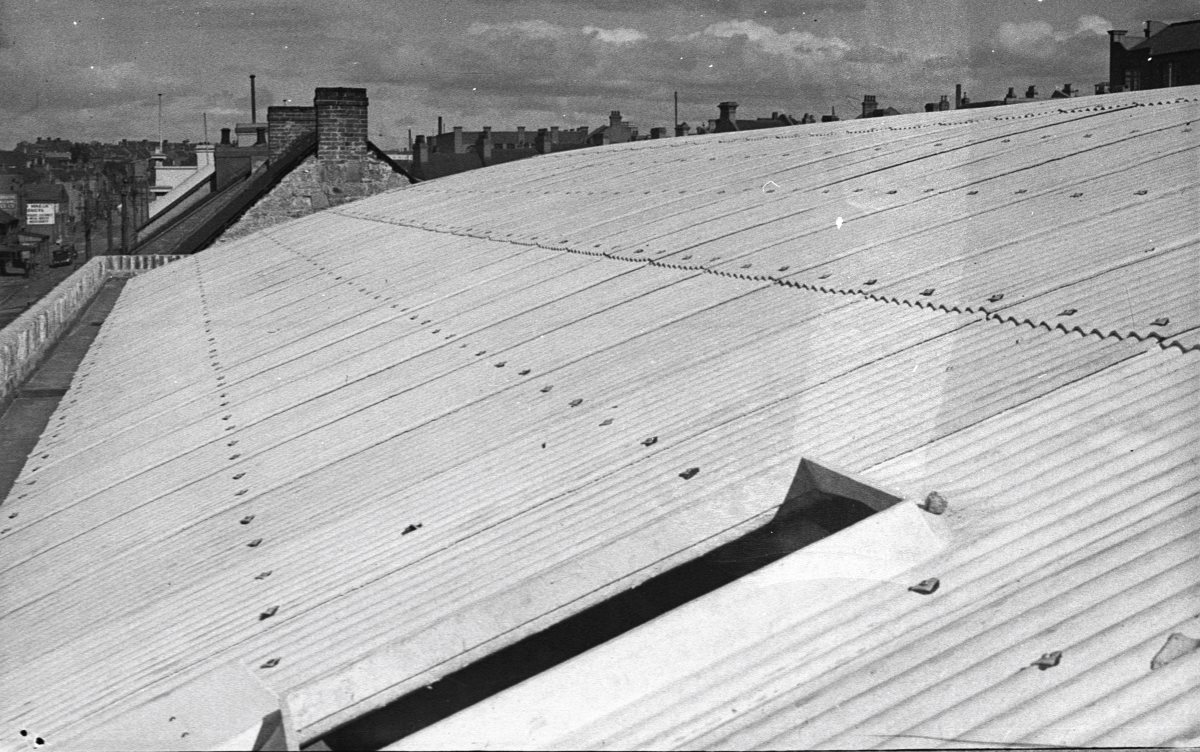

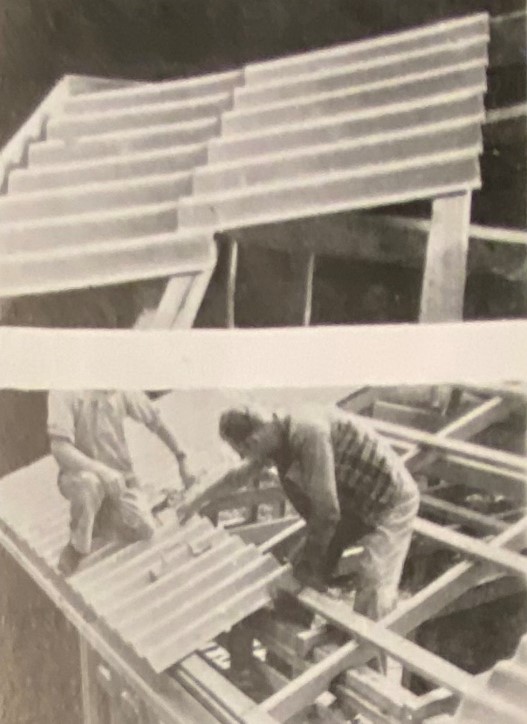

Moulded cement sheeting which has been shaped into a series of parallel ridges for added rigidity and strength.

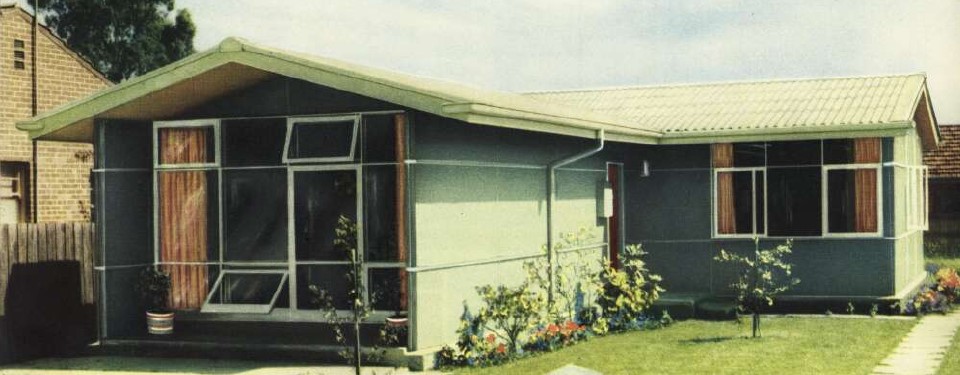

May be painted. Some were coloured red/brown (Tasbestos Trojan Tile – about 1m length sheet).

Average asbestos content was around 15%.

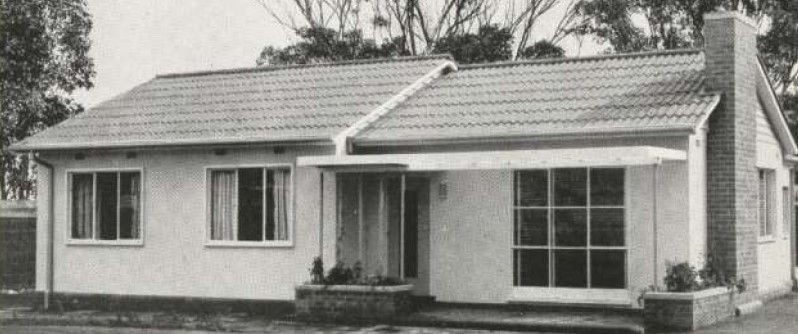

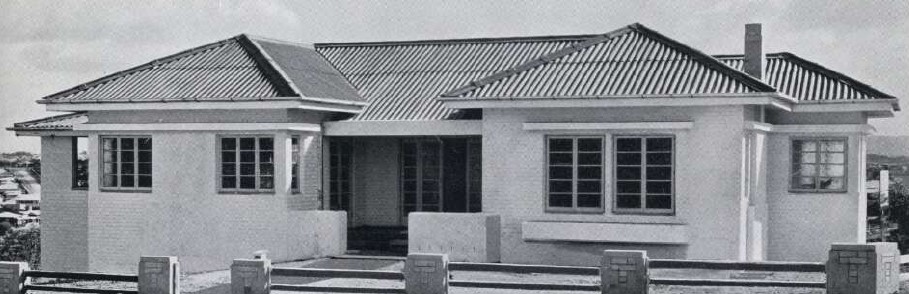

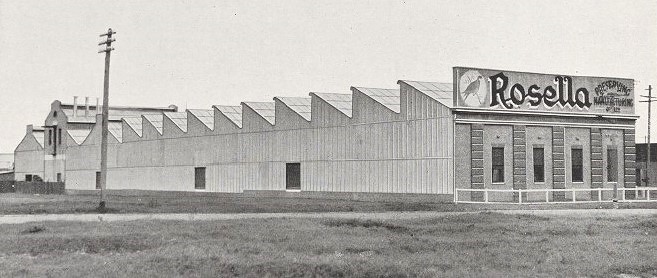

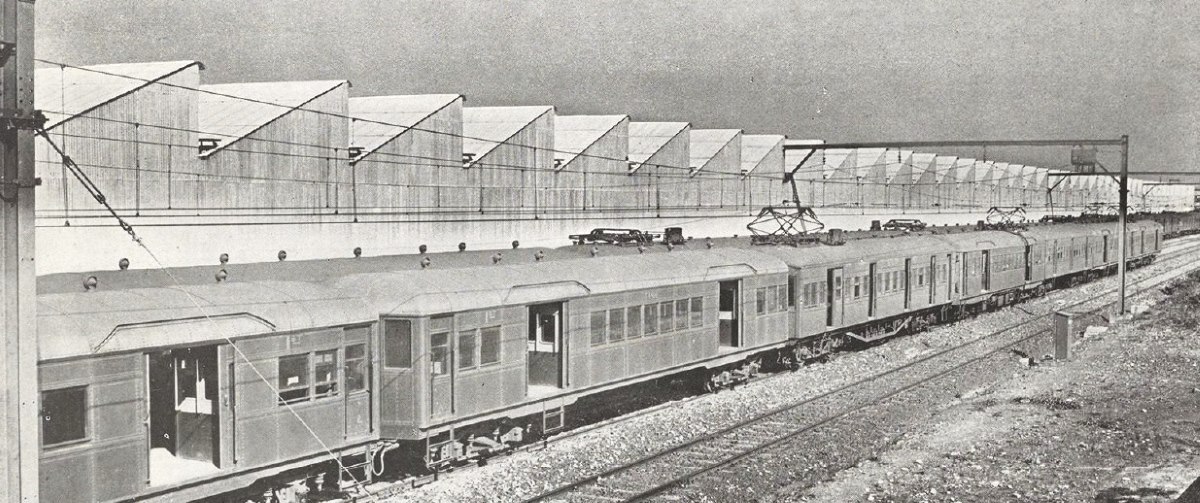

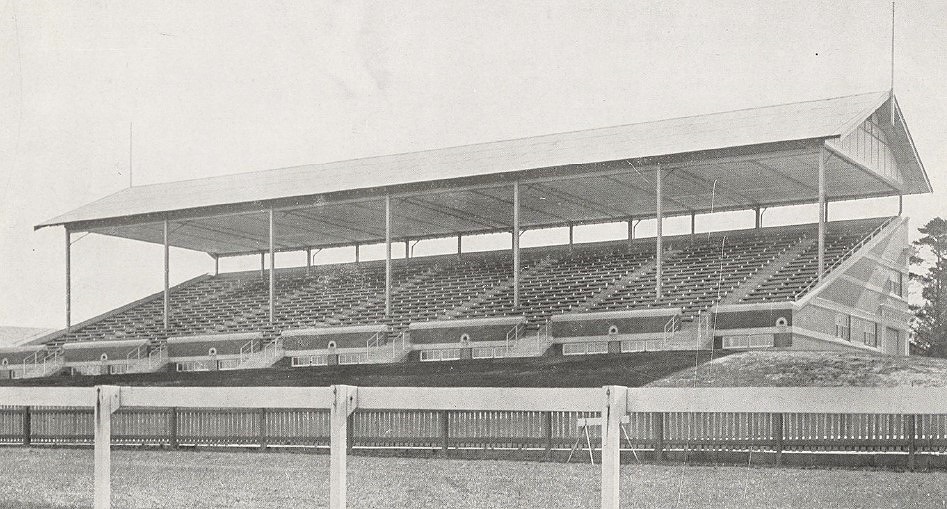

Installed on pitched, single sloping, valleyed and sawtooth roof designs.

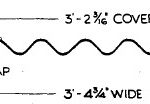

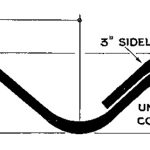

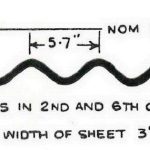

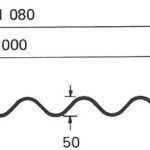

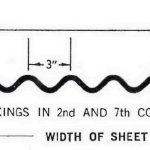

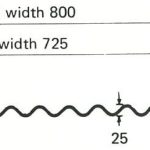

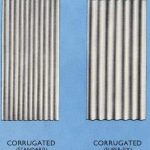

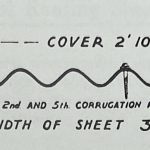

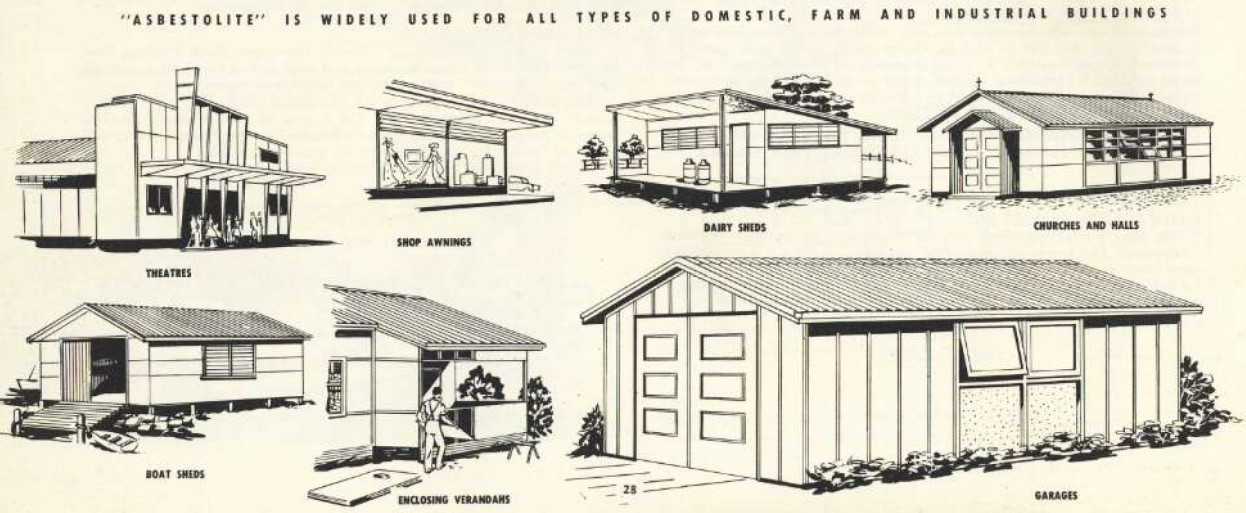

There were two main designs of corrugated sheeting produced in Australia. Firstly, from the early 20th Century, an 11-ridge mould with a half lap on each vertical side which widely sold for roofing as well as exterior siding in industrial applications. In the mid 1920s both Hardies and Wunderlich introduced a corrugated sheet with 7 ridges which were wider and deeper. Hardies marketed the original design as Standard, and the new design as Super Six, both under the Fibrolite brand. Wunderlich named their new design as Deep Corrugated, with both their 11 ridge and 7 ridge designs under the Durabestos brand. Improvements were incorporated to the rigidity of the new design with thicker underlaps. It was also a product more easily less confused with corrugated iron sheeting.

In the post-war years CSR commenced the manufacturing of AC corrugated sheeting with Fibrock Standard 11-ridge and a 7-ridge design branded Master Seven. In Tasmania, Goliath Portland Cement also produced a 7-ridge sheet under the brand Tasbestos.

Super Six became a common term to describe corrugated AC sheeting, despite the continual production and marketing of the smaller ridged products, as well as competing names in the market.

See fixings information page for further about use of bitumen washers/compounds.

Years of production/use

Prior to 1990

Brands/products

- Asbestolite

- Correbestos

- Durabestos

- Fibrock

- Fibrolite

- Fibrobestos

- Super-Six

- Standard

- Tasbestos

- Trojan tiles

- Tuscan tiles

- Master Seven (M7)

- Deep six

- Big Six

Residential uses

- Houses

- Garages, sheds and external toilet buildings, some without roof gutters

Industrial uses

- Pitched, flat or saw tooth roofs

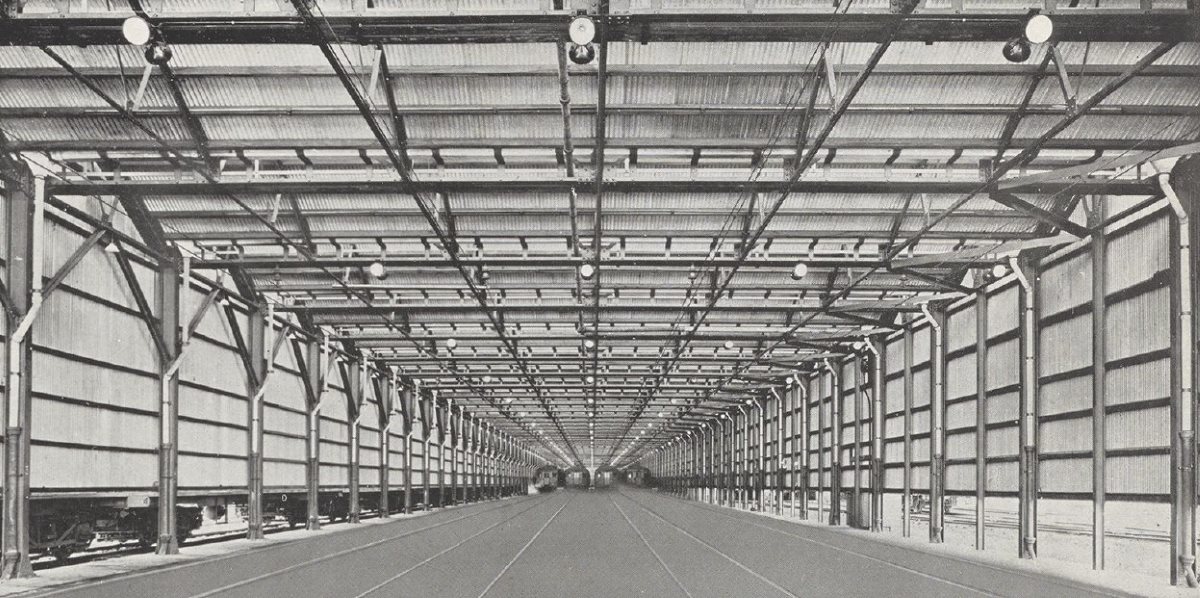

- Foundries, factories, warehouses, electricity substations, workshops, Government buildings, iron/steel works, hospitals, railway structures, theatres, halls, churches, pavilions, service stations, boiler houses, mills, bakeries, baths, dressing sheds, aircraft hangars, abattoirs, engineering works and others

Be aware

Roof guttering and pipework will likely accumulate asbestos debris and dust, as this sheeting is directly exposed to weathering and subject to deterioration. The dust and debris should be considered friable material.

Corrugated sheets expand and contract with weather temperatures. Those sheets in contact with each other rub slightly during this process producing a fine asbestos containing dust which moves to the gutters.

Asbestos dust may accumulate inside structures with exposed interior roof sheeting – framework, existing shelving and lower areas.

Avoid using run-off water for garden or household water tanks for drinking, washing or bathroom.

Prolonged weathering will weaken bonded structure – surface flaking may occur. Moss and lichen and other organic accumulation weakens the bonded structure as root structures allow air and water ingress.

Panels and panel sections may have been used in other applications at same location: fences, retaining walls and for concrete formwork.