Home / Building Structures & Components / Other building components

Bituminous membranes for non-roofing applications

Description

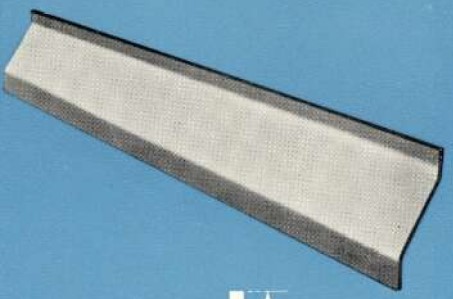

Bitumen (asphalt) based flat sections supplied in flexible rolled lengths. Asbestos may be contained in a layer of the bituminous roll or applied separately as a felt layer first with an asphaltic membrane covering.

Used for weather and water proofing.

Usually applied by rolling out the membrane onto a surface and applying heat (flame) to partially melt the compound and provide adhesion to the surface being applied to.

May be inserted into expansion joints.

Brands/products

Nurolite

Years of production/use

Prior to 2003

Residential uses

Paved areas, apartment block surrounds, moisture proofing of interior areas such as cellars and split level flooring.

Industrial uses

- External mezzanines, decks, upper floor walkways on commercial buildings, concrete pavements, driveways, brick wall expansion joints between extensions, flashing

Be aware

Exposed edging and sections subject to waterflow may be a point of increased deterioration, exposing fibres.

Learn the history of the site – asbestos containing bituminous membranes may have been encapsulated.

Non-ACM bituminous membranes are still widely used.

Home / Building Structures & Components / Other building components

Compressed flat asbestos cement sheeting

Description

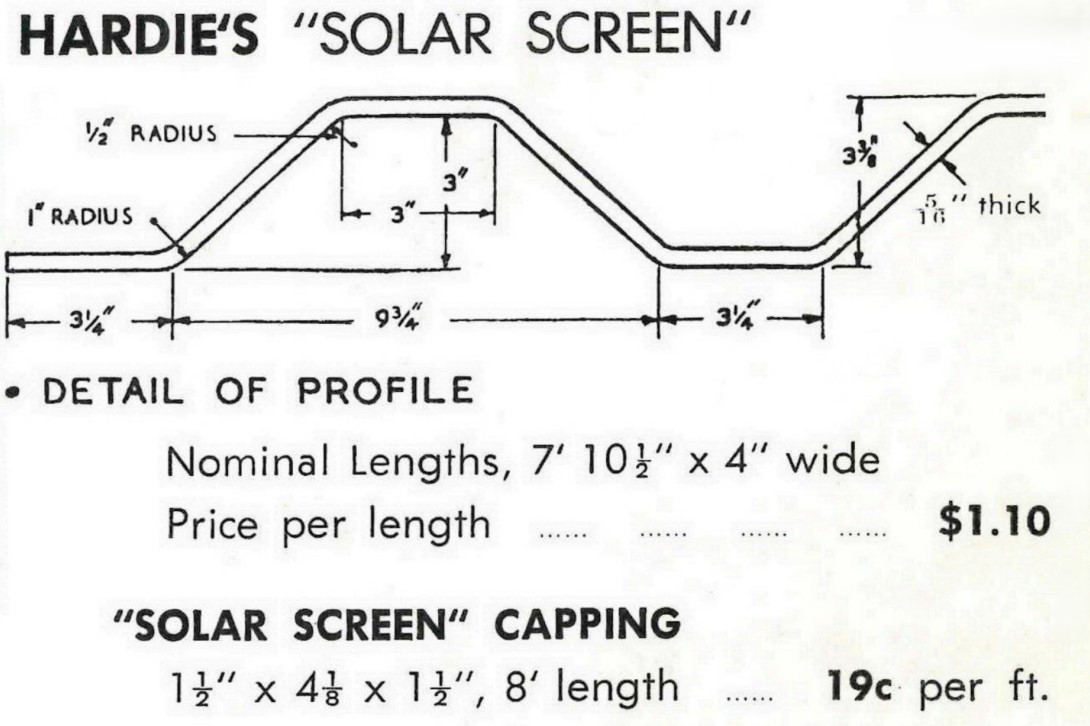

Compressed, high density AC sheet with double face, thicker than common AC flat sheeting. Sold in square or rectangular panels. Smooth face both sides or with single side non-skid patterned face.

1980 specs show production was in thicknesses of 6mm, 9mm, 12mm, 15mm, 18mm and 24mm.

Internal and external use. Developed for weather-proof, moisture-proof applications.

A dense, high strength, building product for bathroom/toilet partitions in commercial premises and public buildings, spandrel panels and porch flooring. Advertised for curtain walls, balustrades on bridges and balconies, stairtreads, bathroom floors, underlay for tiles, suspended decks, sub-floors, sun louvres, windowsills, tunnel linings, laboratory bench tops and permanent formwork applications such as bridge decking. Advertised as able to be applied directly to joists.

Hardie’s technical publications for the construction of decking with compressed sheeting recommended the use of AC spacing strips (offcuts) and AC internal angles as base moulding (1980).

Brands/products

- Fibrolite

- Fully compressed thick sheets

Years of production/use

Late 1960s-1980s

Following the cease of asbestos use, Hardie’s manufactured an identical cellulose fibre product under the name Compressed Sheet II. This may be branded on the underside edging. If unsure, sampling for testing by a NATA accredited laboratory is the only method of confirming the non-asbestos product.

Residential uses

Decks, landings, flooring, balustrades on multi-storey apartments

Industrial uses

Balustrades on bridges, toilet and changeroom partitions

Be aware

Weathering combined with direct contact such as foot traffic, will have increased damage effect.

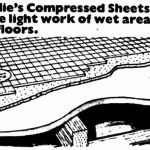

External decking with a compressed sheet upper surface may have a second layer of AC sheeting installed underneath, separated by sarking.

Home / Building Structures & Components / Other building components

Concreting and support formwork

Description

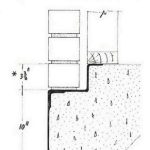

AC sheeting or pipes used as formwork or shuttering for shaping, reinforcing or underlaying concrete pours. Permanent formwork or temporary. AC products left in-situ as permanent formwork may not be visually apparent as AC due to the similar colour to concrete, particularly if painted.

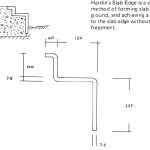

Hardie’s marketed a 2.7m set shaped slab edge for DIY concreters.

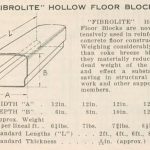

Up until around the 1940s, Hardie’s manufactured AC Hollow Floor Blocks, an alternative to (Coal) coke breeze blocks, which were a popular method used in the late 1800s into the 20th Century to reinforce concrete. Breeze was small cinders and cinder-dust (extinguished partially burned coal). This was mixed with cement, cast in wooden moulds, and made into blocks. The AC product provided other advantages as advertised.

Brands/products

- Any brand product

- Fibrolite

Years of production/use

- Slab edges – produced to mid-1980s

- Hollow floor blocks – Late 1920s-1940s

- Ad-hoc use of other material is an ongoing issue

Residential uses

BBQs, DIY construction, framework support

Industrial uses

Ad-hoc concrete infills, older bridges

Be aware

DIY construction decisions may dictate use in unexpected situations.

Painted AC may display dimpling pattern.

Home / Building Structures & Components / Other building components

Asbestos cement louvres

Description

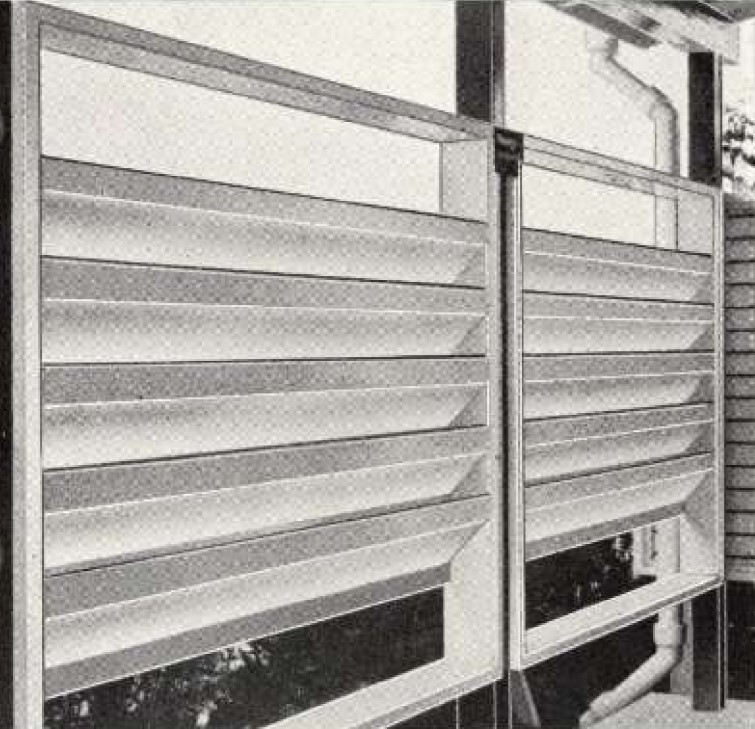

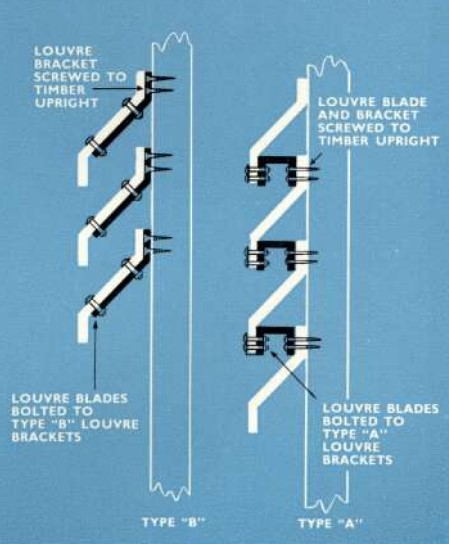

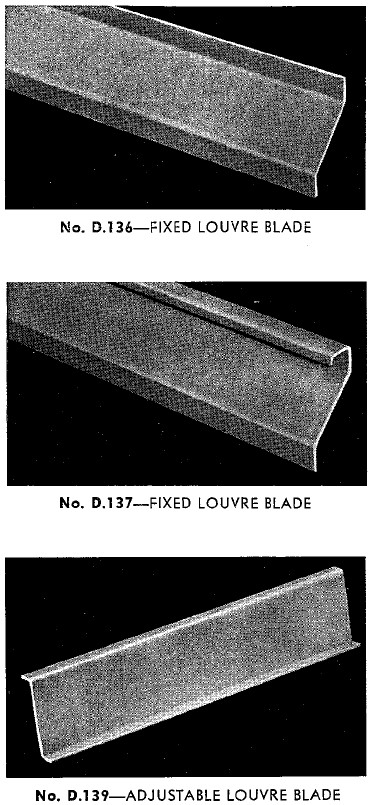

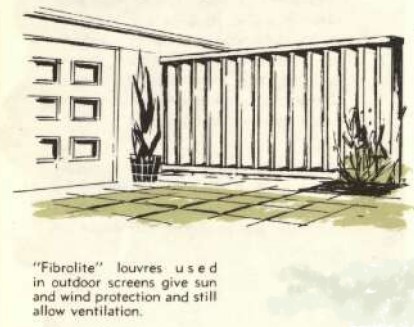

Louvres to allow air flow into structure. May be moulded AC fixed into place (horizontal or vertical) with gutter bolts and no hinged movement, moulded AC for fitting into adjustable (hinged) frames, or adapted AC sheeting cut and placed into hinged frames that allows open and closing.

Years of production/use

Prior to 1990

Brands/products

- Fibrolite

- Durabestos

- Any AC sheeting

Residential uses

- Window systems in tropical locations

- Attached car ports, garages, screening

Industrial uses

- Ventilation installed within for flat walling on warehouses, plant structures

- Ventilation for HVAC cooling towers

Be aware

Environmental damage to exposed flat surfaces

Home / Building Structures & Components / Other building components

Modular homes with asbestos components

Description

Modular (kit) homes marketed from mid 1970s-1980s. AC panelling manufactured by Hardie’s, or other components potentially containing asbestos.

- Logan Homes

- Trojan Home-Pak

Logan Homes

Franchises throughout Australia and South Pacific. Generally known in Australia as Logan Homes.

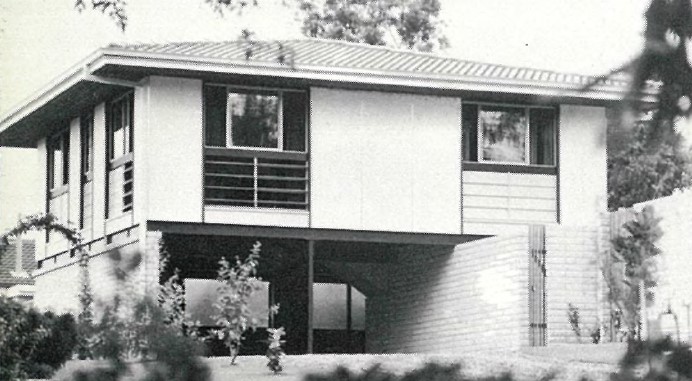

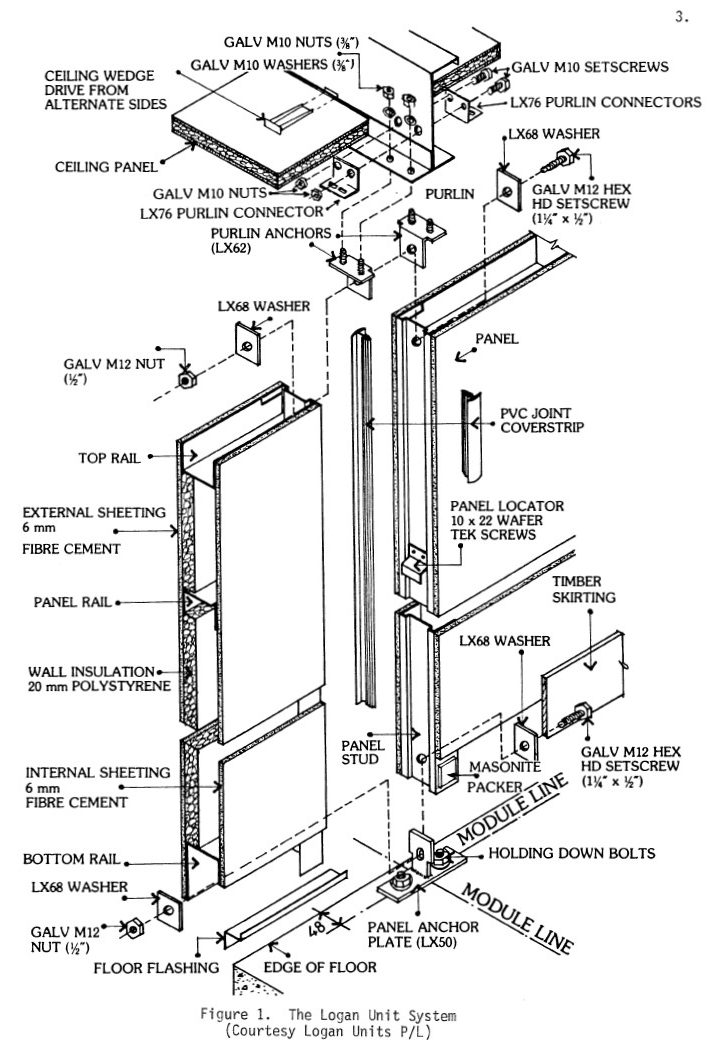

An early version of prefabricated expanded polystyrene sandwich (EPS) panelling was a key element of the modular system in the Logan Homes (refer image 8), used for walls and ceilings.

Ceiling panels were solid sandwich panels of AC sheeting with a polystyrene core. Wall panels were AC sheeting attached to metal frames requiring polystyrene batts to be inserted.

Later designs from the mid-1980s saw the AC sheeting layers replaced with non-ACM fibre cement sheeting.

Marketed as a quick and cheaper housing alternative, which was cyclone proof, able to be constructed by a ‘handyman’ in weeks. Attractive to buyers in cyclone-subjected locations.

Diagram at image 8 is from published James Cook Cyclone Structural Testing Station report:

Testing a Logan Unit House Designed for 63m/s Winds – 1984.

- Both AC sheeting and fibre cement sheeting are referenced in this report as located in the structure tested.

Trojan Home-Pak

Manufactured by Joyce Industries based in WA where it is believed most sales were achieved. A choice of 6 house designs with Greek names such as Eros, Apollo and Propylaea.

Supplied components included a choice of non-asbestos products or of the following asbestos products:

Roof:

Super Six AC corrugated roof

Decramastic tiles

AC Exterior walls:

Hardiflex sheeting

Hardiplank Smooth or Woodgrain

Montana or Stucco siding

Coverline or Highline moulded sheeting

Interior:

Ceiling with sprayed on vermiculite (Possibly contaminated)

Versilux AC Walls in bathroom

Other building companies named Trojan Homes did or do exist, not related to this organisation.

Brands/products

- Logan Modular Homes

- Logan Unit Homes

- Pacific Modular

- Marlin Modular

- Trojan Home-Pak

Years of production/use

1970s to early 1980s (ACM risk).

Advertising in March 1984 stated that about 14 Logan Homes were being built every day. Around half at this time, were in Queensland.

Residential uses

Housing

Industrial uses

Community buildings, mine site accommodation and field offices

Be aware

Some cases of mixed panelling (AC and non-ACM) supplied within kits appears to have occurred in mid-1980s. Multiple sampling may be required during asbestos surveys.