Home / Machinery & Fixed Plant

Asbestos insulation material – maritime

Description

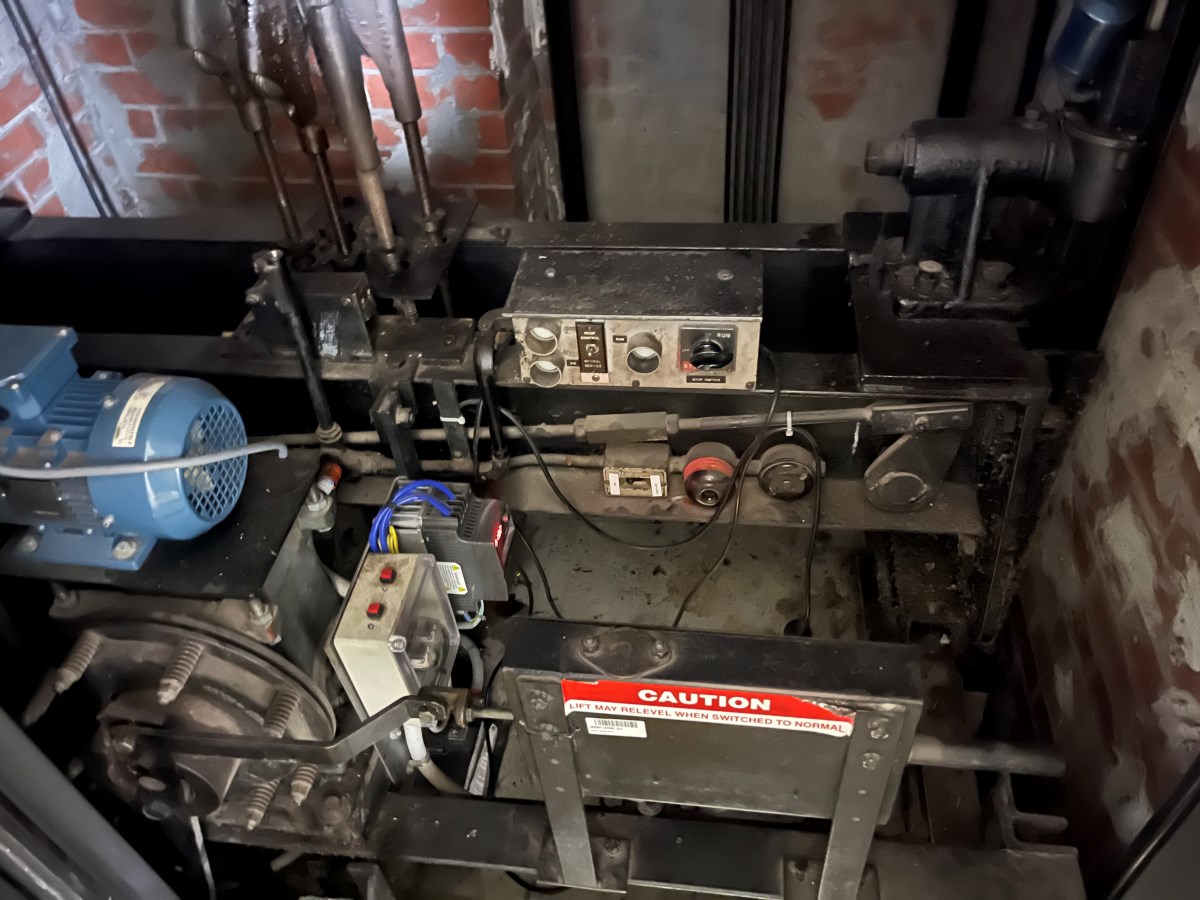

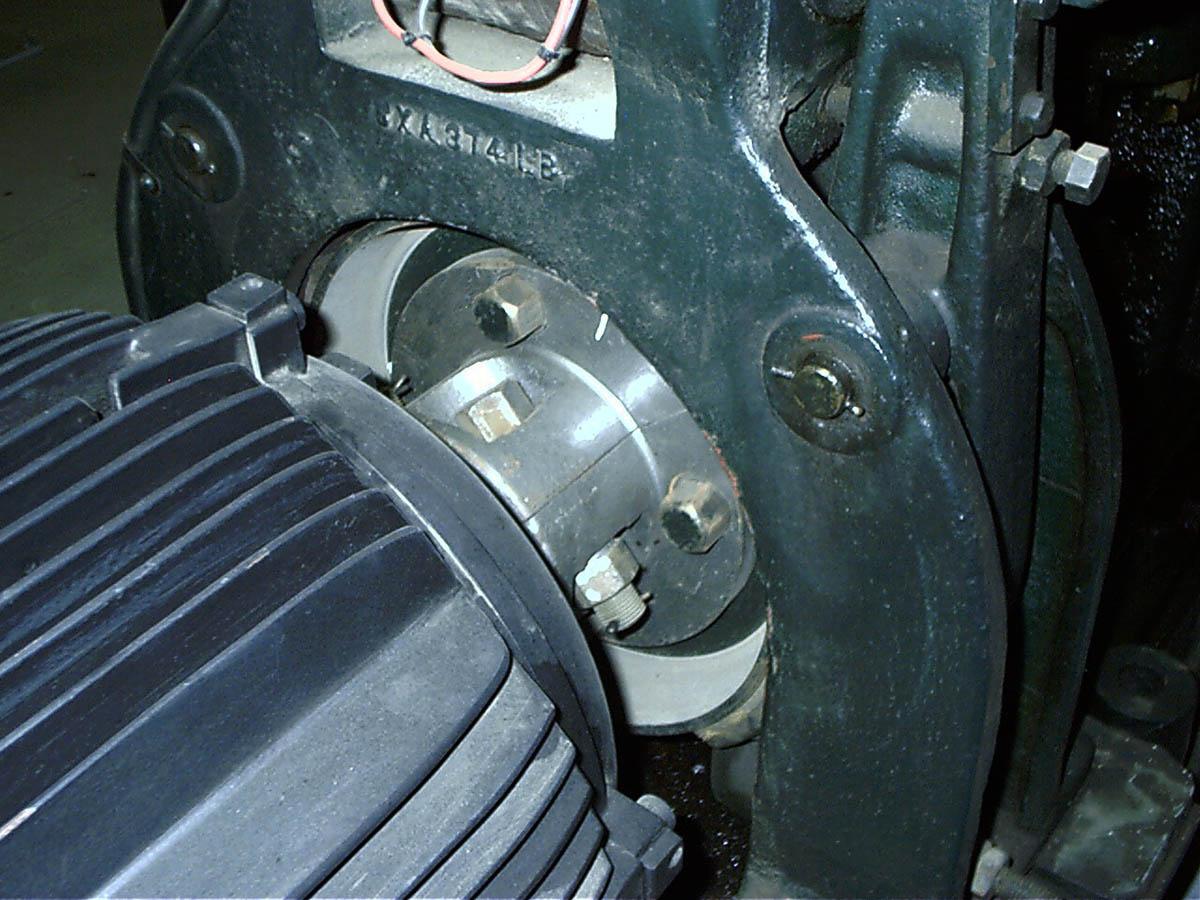

The use of asbestos on maritime vessels has a long history. Confined spaces with fixed plant and heat generating machinery require substantial insulation materials.

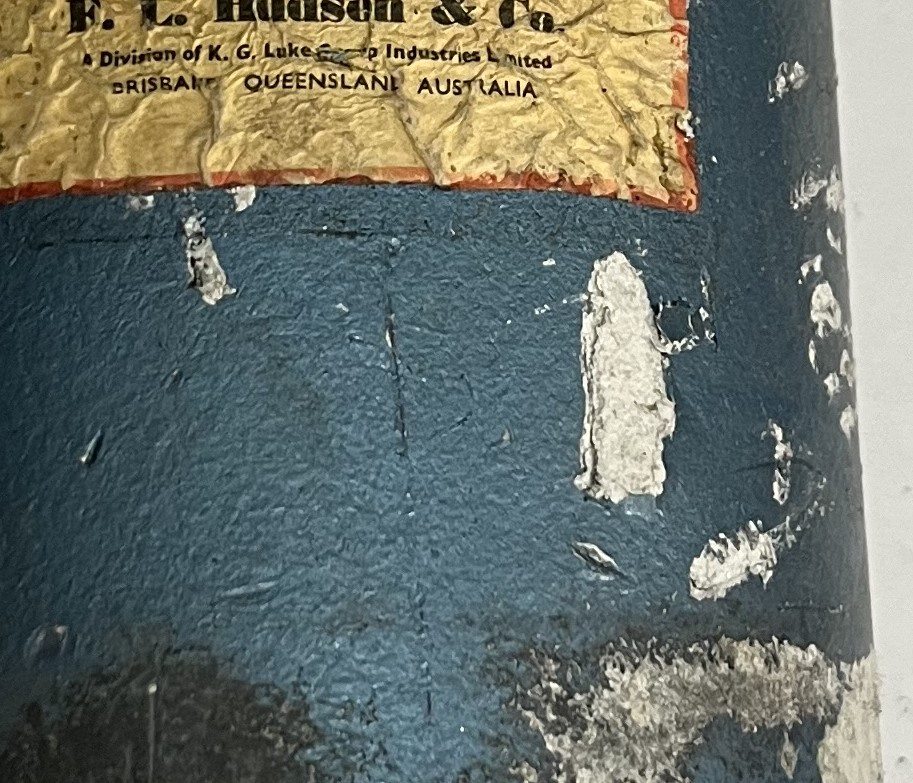

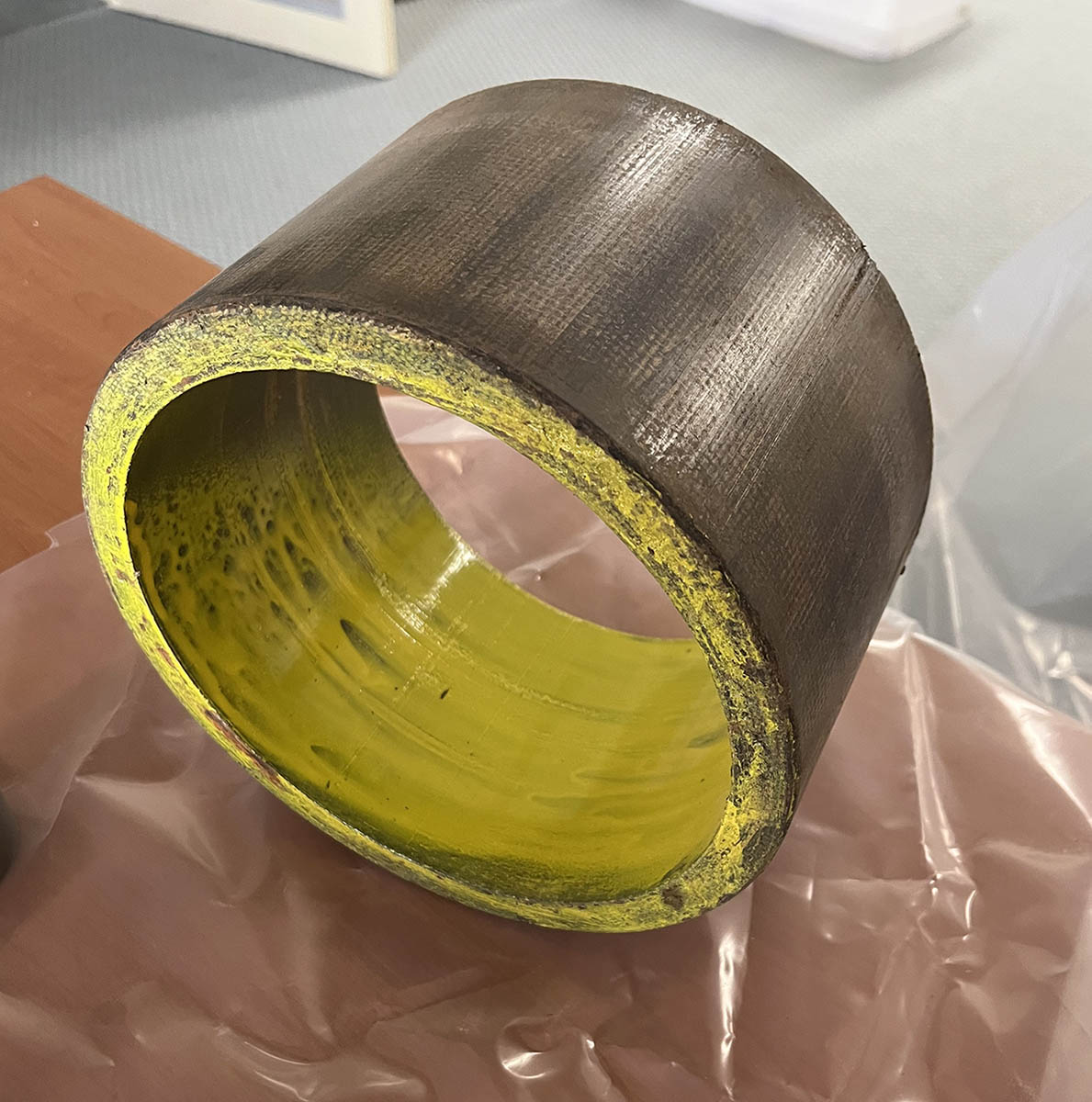

Exhaust and pressure piping were often wrapped or lagged with ACM for insulation, fire prevention and crew protection from heated surfaces.

Pressure piping insulation may be covered with nylon or non-asbestos textile materials. Damaged or poorly maintained covers can expose ACM.

See also: Woven asbestos textile for insulation and other ACM for piping in Insulation.

Ships built after 1 July 2002 are not permitted to contain asbestos in line with IMO SOLAS regulations.

Brands/products

no list

Years of production/use

- Prior to 2002.

- Still used in certain countries and represents risk to after-market parts supply.

Residential uses

Older house boats or cabin cruisers

Industrial uses

Older Australian vessels.

Older vessels sourced from outside Australia.

Be aware

ACM may be encapsulated, or may encapsulate non-asbestos insulating material such as mineral wool.

Damaged ACM in a confined space, such as a pipe tunnel, engine room or engine bay, may allow for settled asbestos dust on surfaces.