Home / Insulation / Page 2

K-Lite insulation material

Description

Light weight insulation material, when initially produced, was for temperatures up to 650°C. In 1961 an improved production method was introduced which allowed for temperatures up to 815°C. Hardies stated that by 1966

K-Lite represented around 60% of total insulation materials they produced.

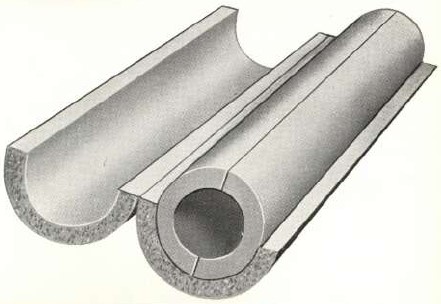

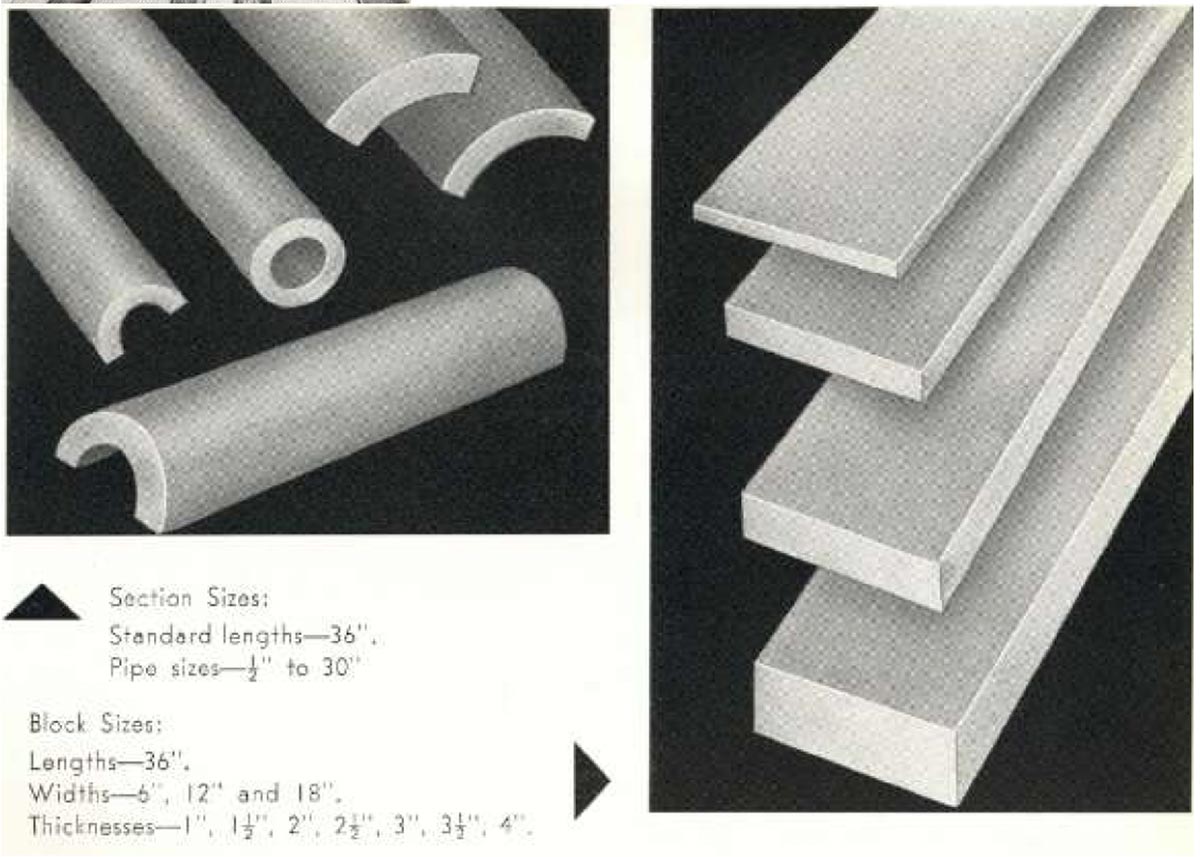

Manufactured under licence in Australia, the original product was known as Kaylo insulation. Produced in blocks, radiused sections for pipes, and used in electrical conduits and arc chutes.

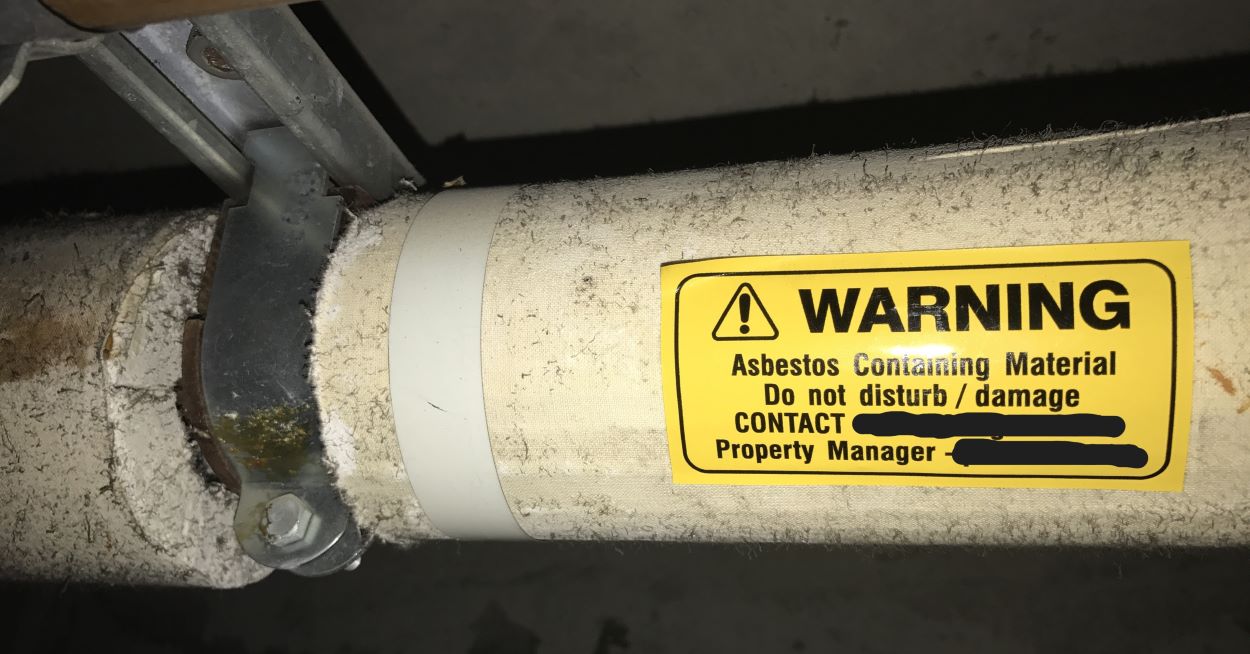

The product was composed of 10-15% amosite asbestos and 85-90% hydrous calcium silicate.

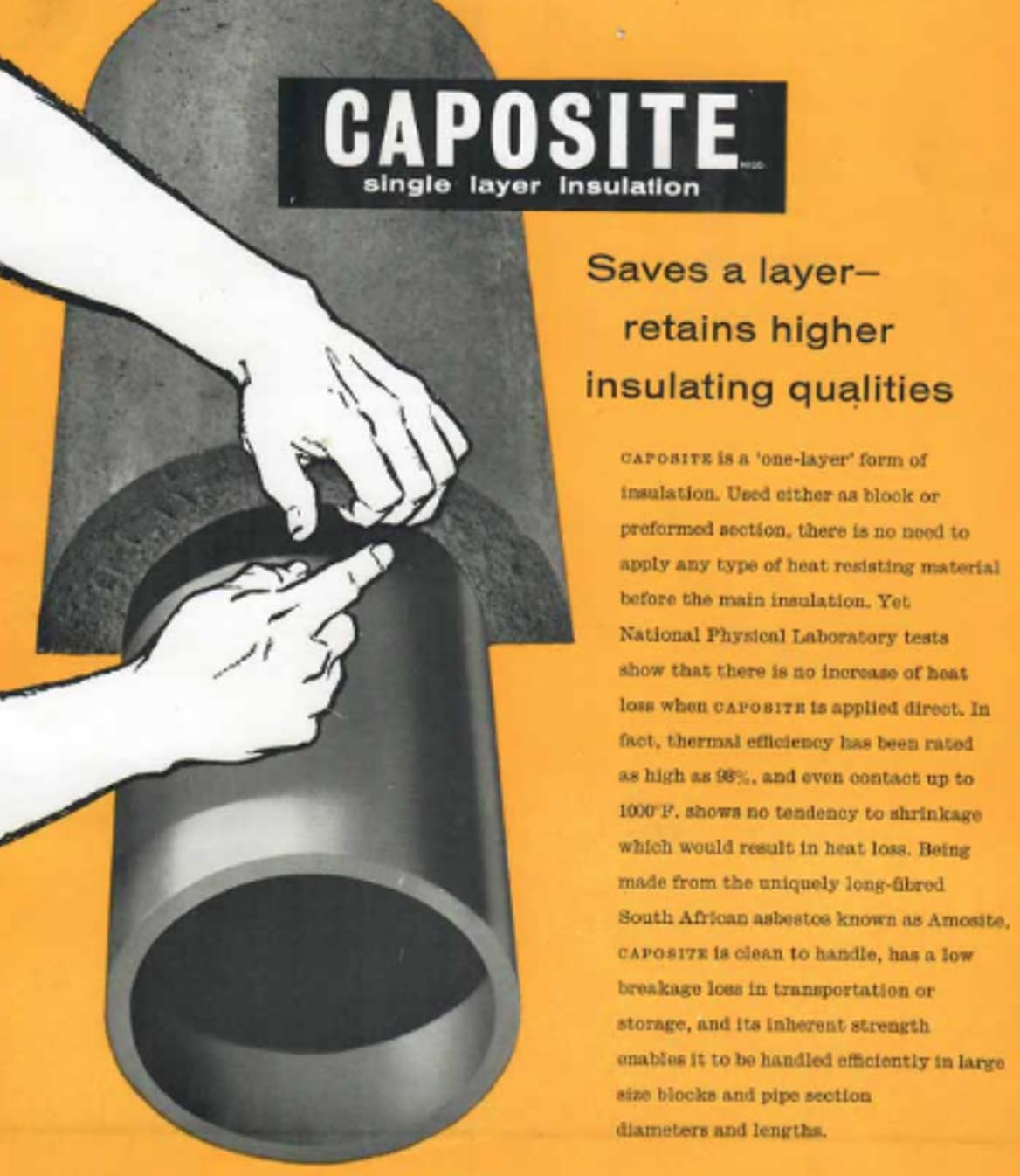

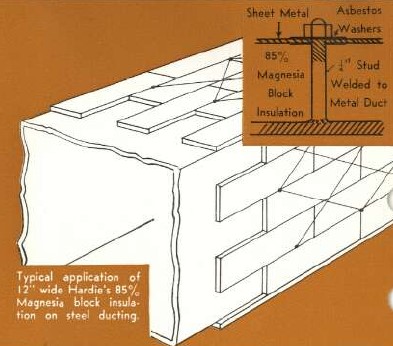

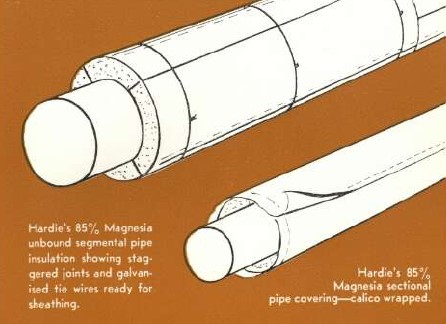

Used in layered insulations with Caposite and 85% Magnesia. See Industrial combination insulation page.

Brands/products

- K-Lite

- Hardie-BI Co

Years of production/use

1953-1974

Between 1964 and 1971 Hardie’s produced it under an agreement with Bradford Insulation Industries and CSR. CSR supplied crocidolite (blue) asbestos to Hardies in this period.

Supply to the market occurred through installers such as Bradford Insulation and Bell’s Thermalag to name two.

Residential uses

Possibly used in domestic heating applications for pipe lagging.

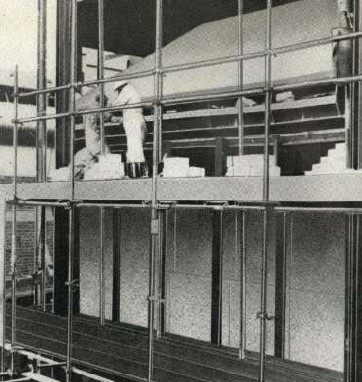

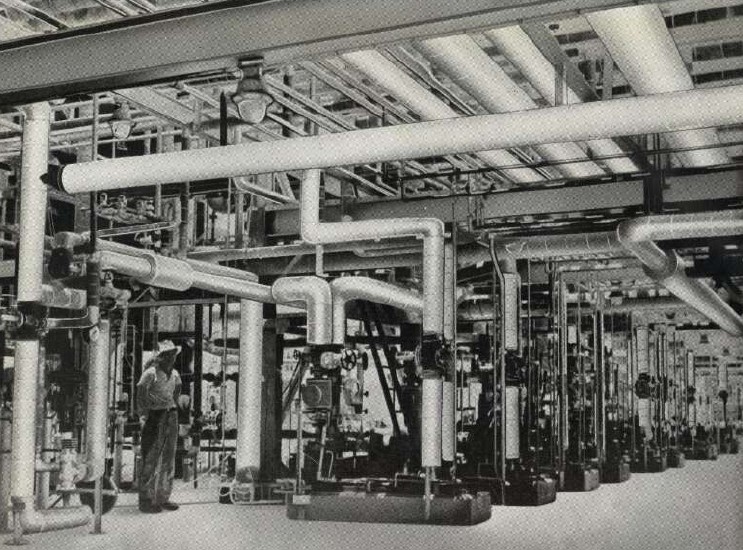

Industrial uses

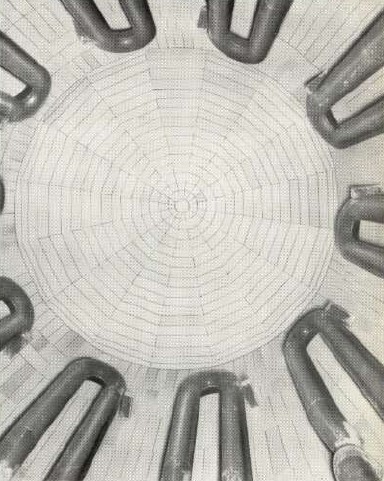

- Advertised for autoclaves, furnace walls, boilers, heat exchangers, hot air ducts, kilns, ovens and precipitators.

- Also used within fire doors. See asbestos (core) in fire doors page.

- Breechings, tanks, dryers, evaporators, condensers, autoclaves, turbines, chilling pits and locomotives.

Be aware

Designed to be hand-cut to shape/size on site, which exposed fibres.

Pipes may be recently encapsulated with other insulation material such as jacketed fibreglass or mineral wool.