Home / Insulation

Loose-fill asbestos insulation

Description

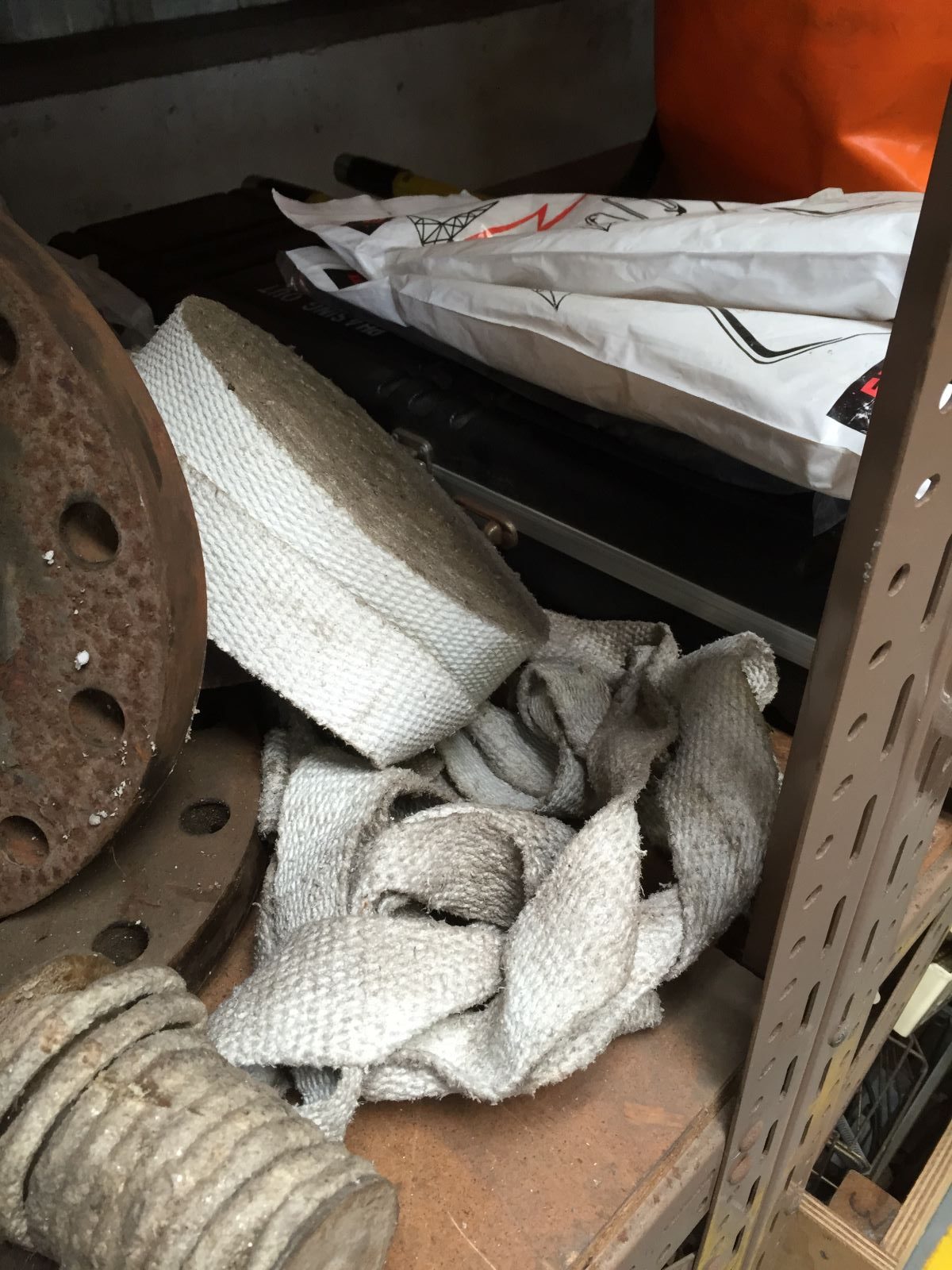

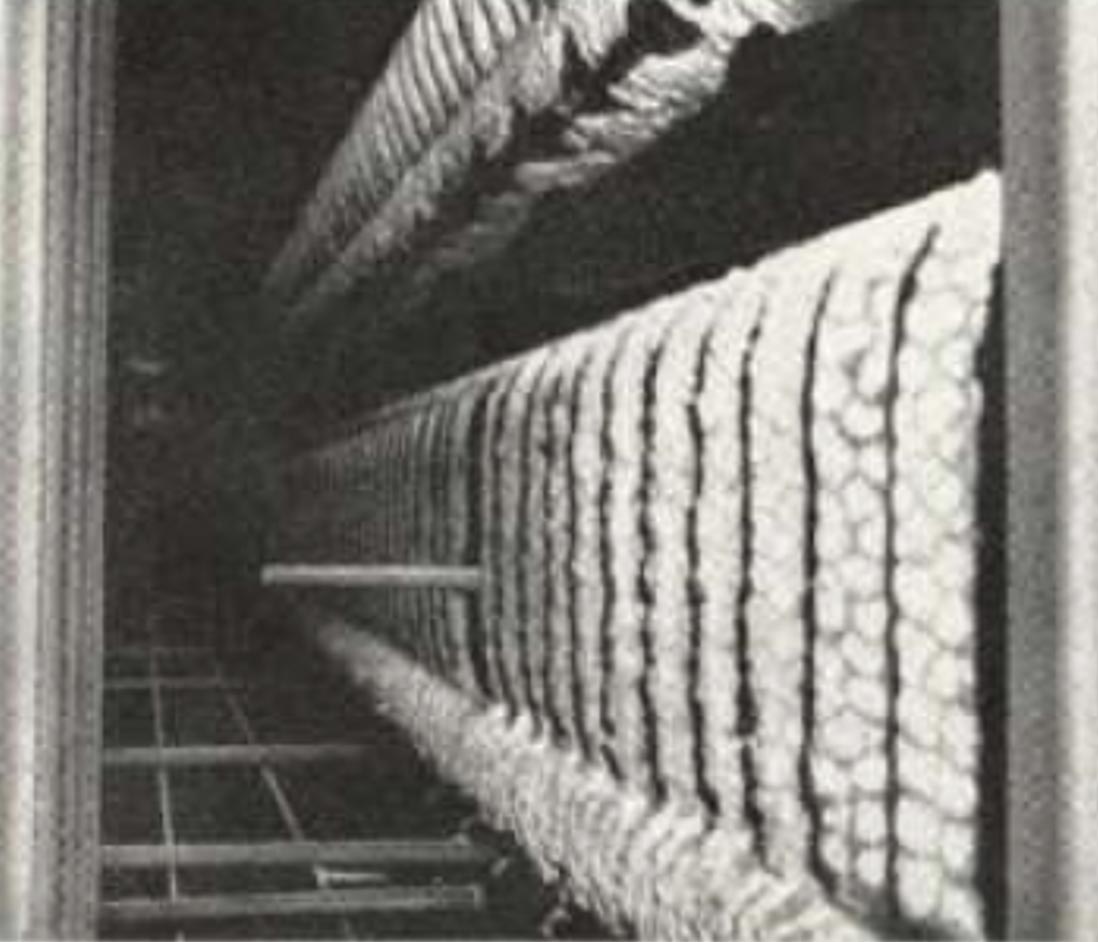

Classified as friable in every Australian state and territory.

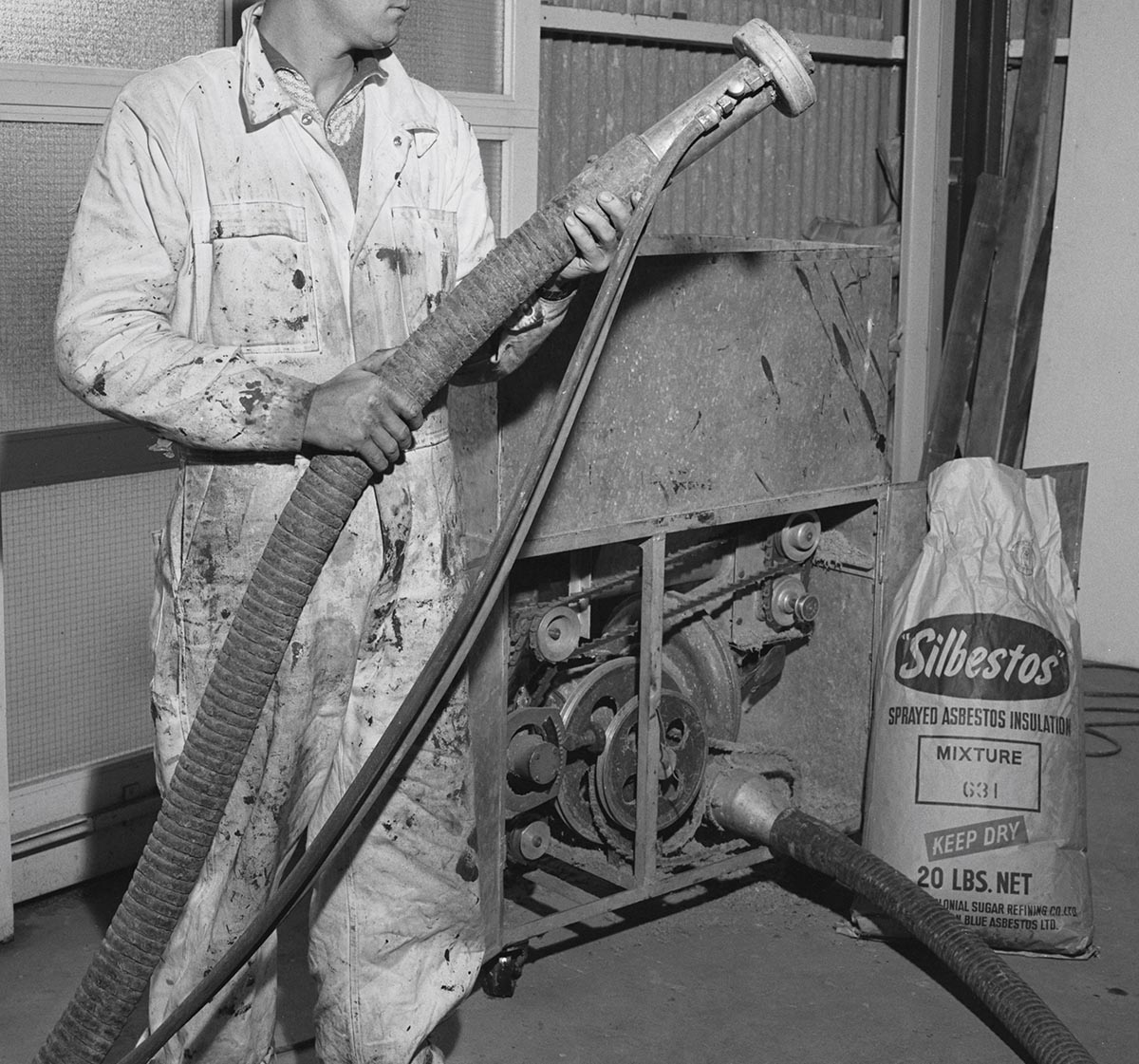

Loose asbestos fibres (usually South African sourced amosite asbestos) pumped from a truck-based hopper via a hose into the ceiling space of the structure. Depth of insulation was around 5-6.5cm (2-2.5”) when complete.

May be in-situ as the sole insulation or covered with non-ACM material such as batts.

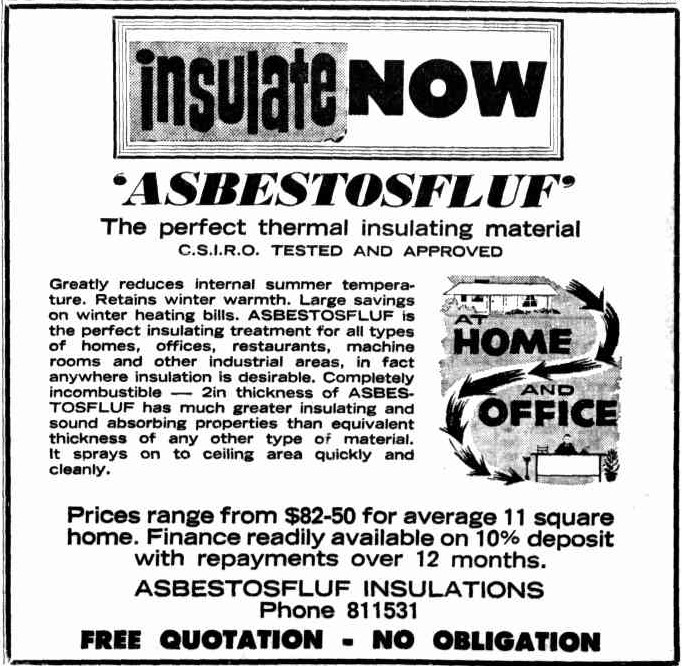

Asbestosfluf (commonly known under the name Mr Fluffy) was a material installed in residential structures between 1968 and the early 1980s.

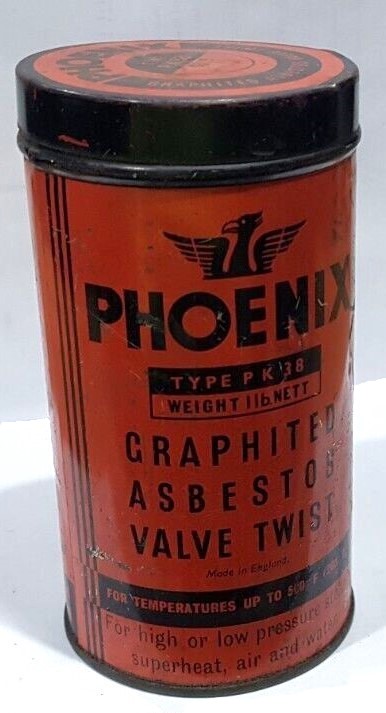

Brands/products

Asbestosfluf

Bowsers Asphalt (NSW)

Years of production/use

Mid 1950s to early 1980s

Residential uses

Ceiling space

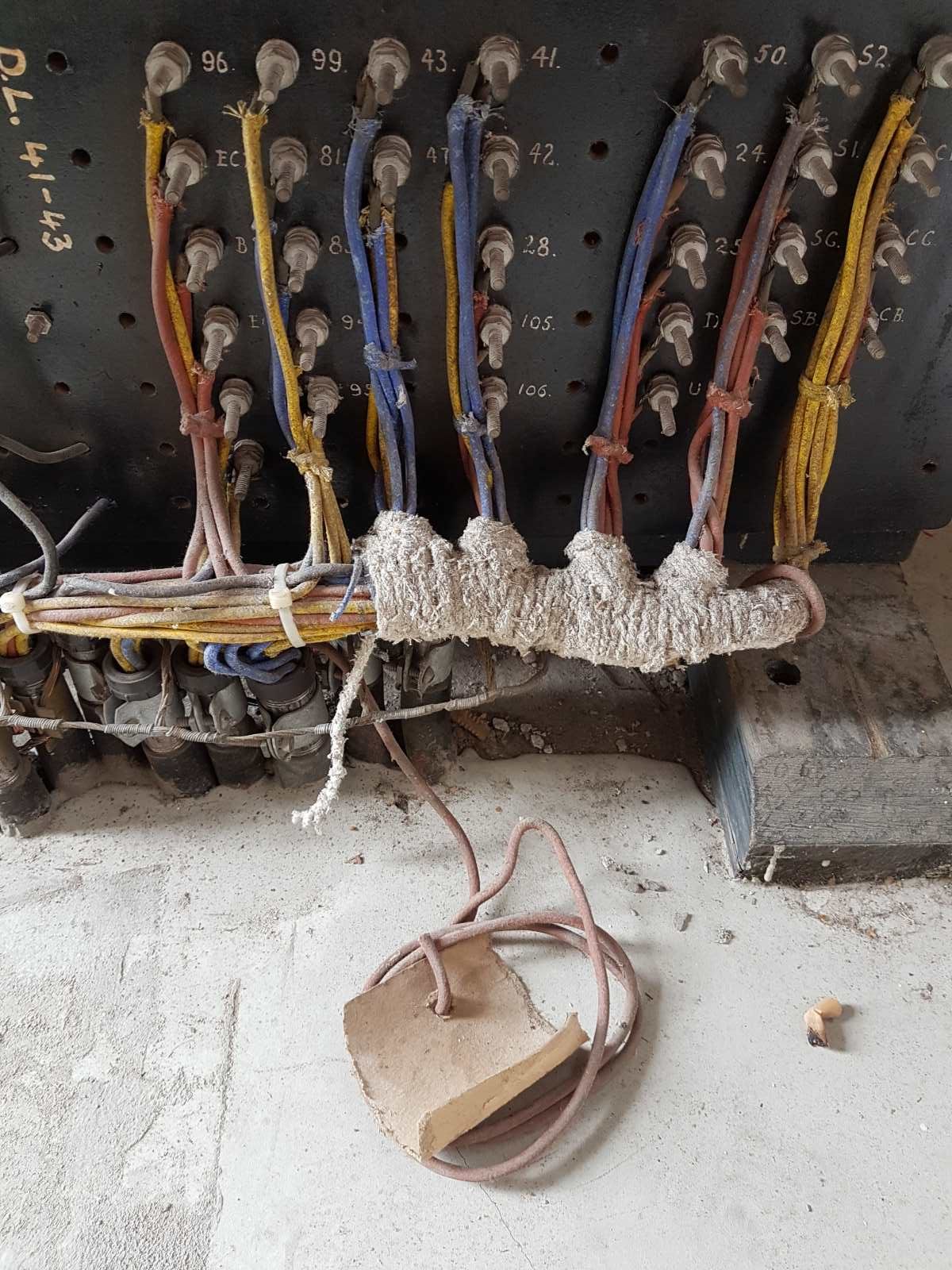

Industrial uses

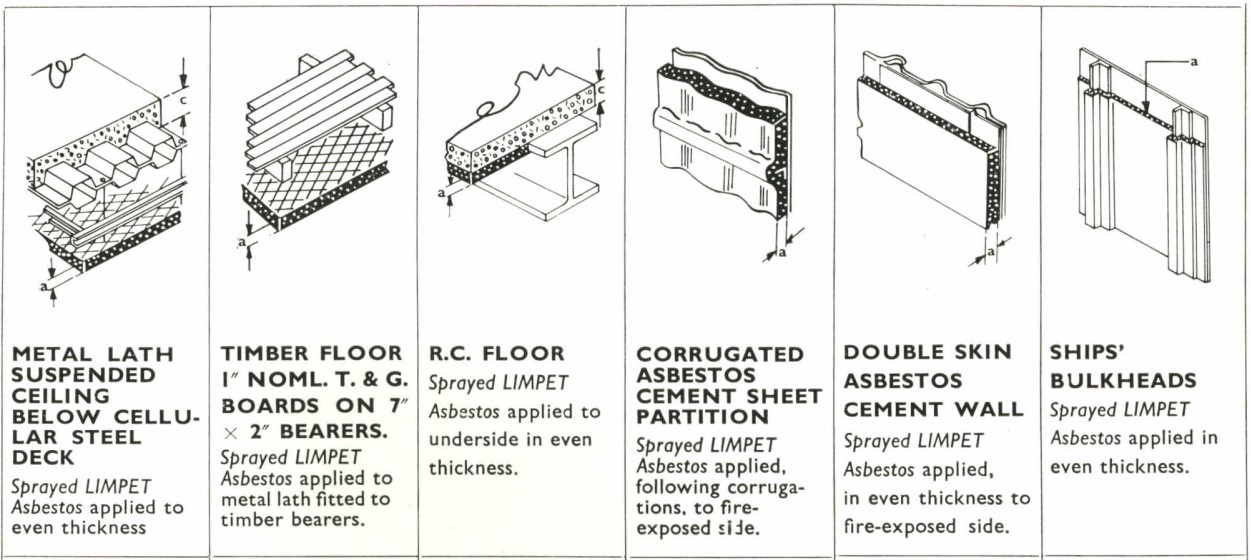

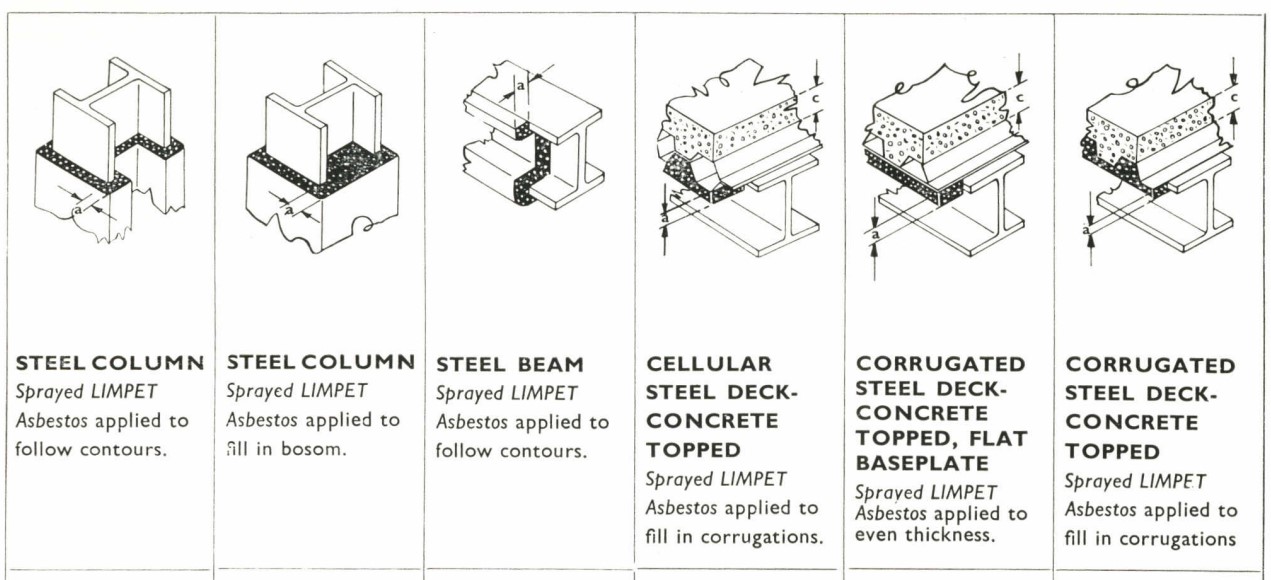

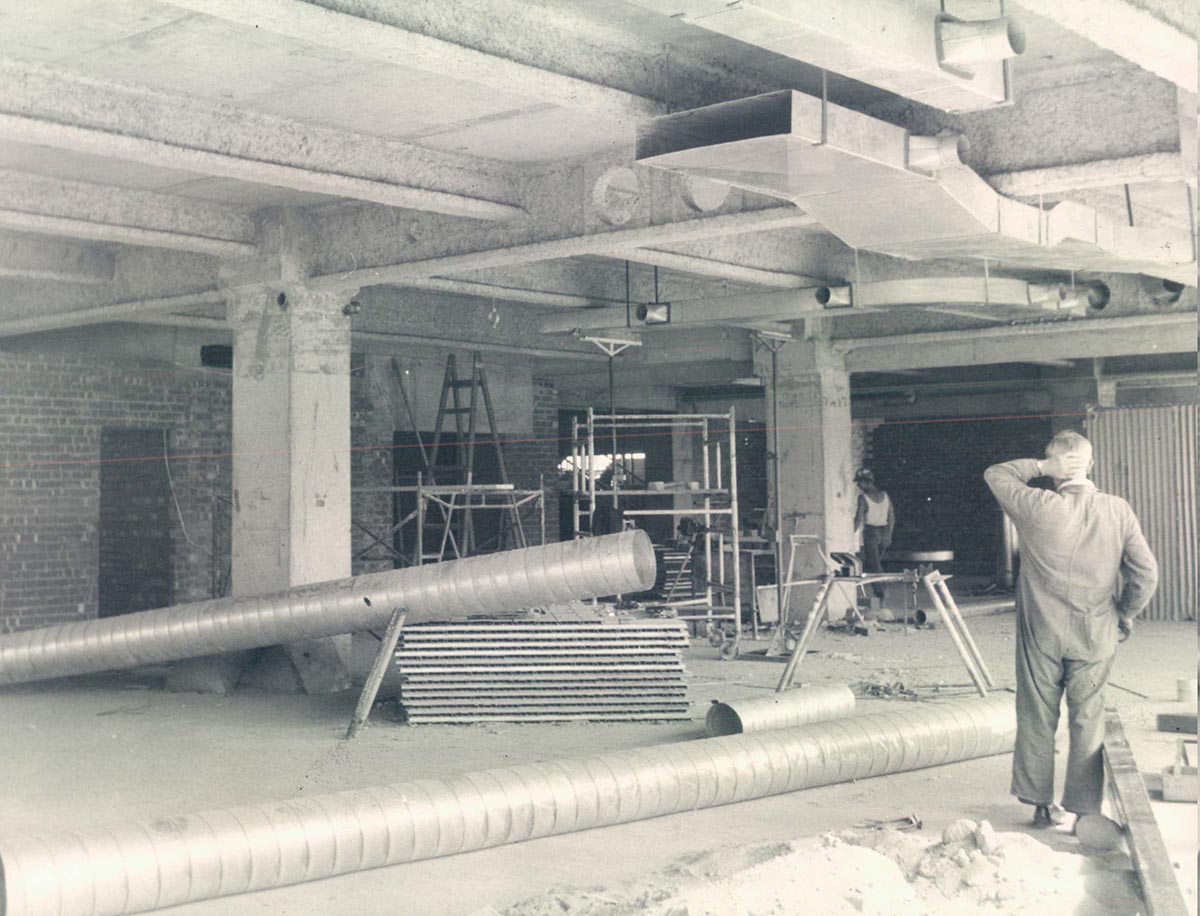

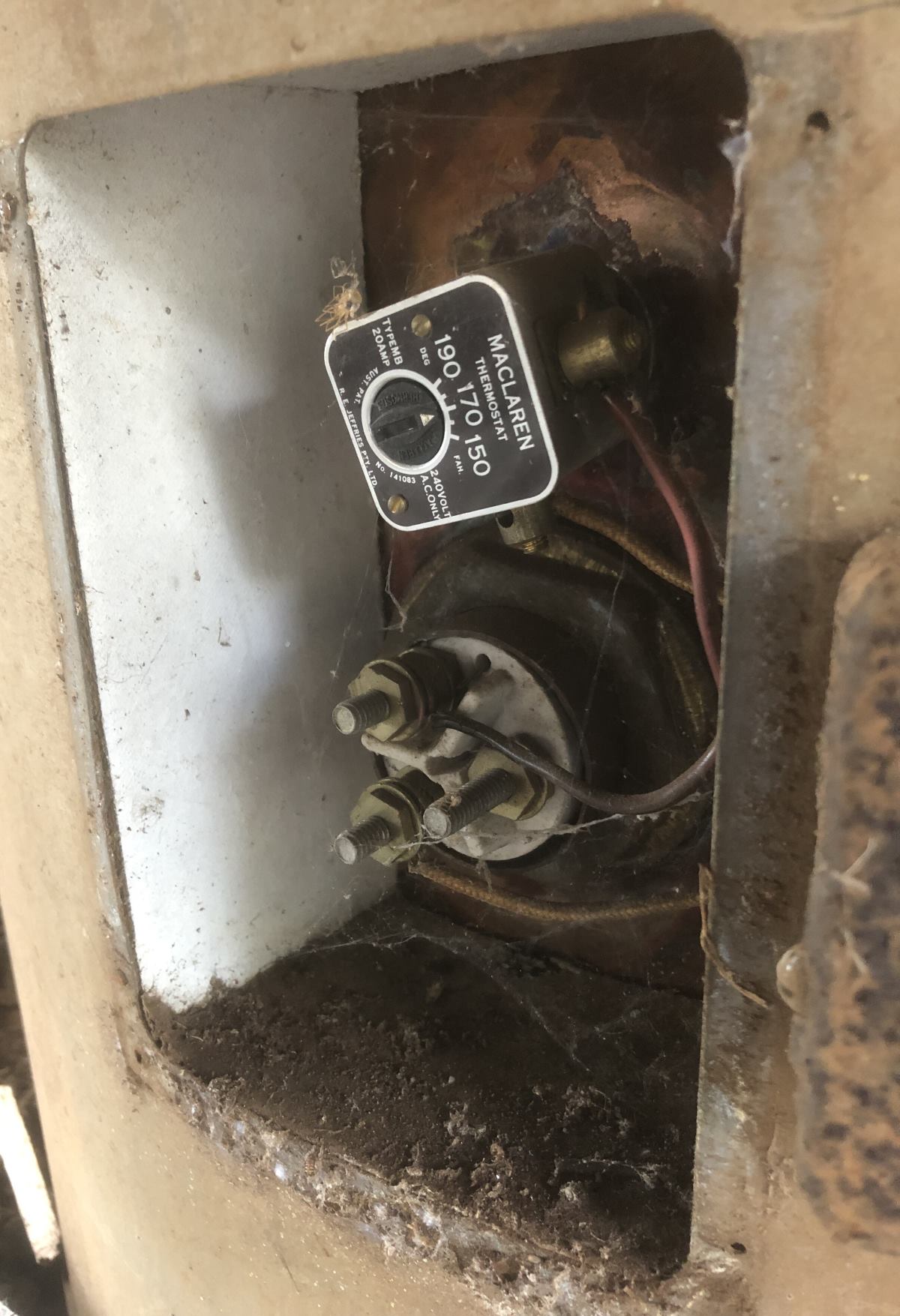

- Commercial ceiling space above structures that required consistent temperature control such as cool rooms, freezers, food storage, laboratories etc.

Be aware

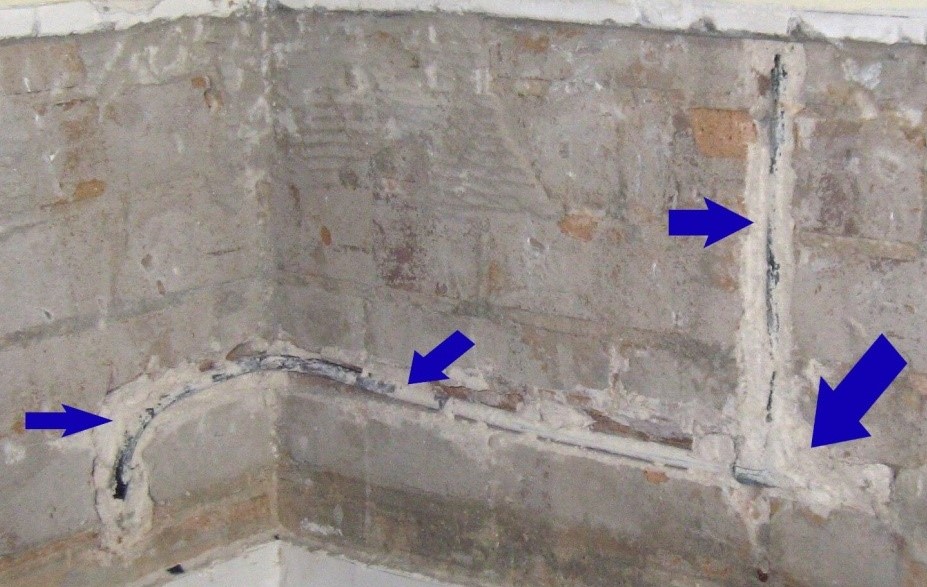

Spacings, cracks or perimeter spaces that provide air ingress from ceiling space may provide avenue for respirable asbestos fibres into other areas. Examples: manholes, recessed light fittings, skylights and installation points over other fittings: exhaust fans, ventilators (ceiling and wall), loose panels above enclosed cupboards as well as damaged or loose cornices, ceiling and wall sheeting.

Settled dust with asbestos will likely occur at ceiling space escape points on structures that remain undisturbed for long periods: tops of architraves, inside top areas of linen cupboards, built-in wardrobes, ceiling ventilation grills, seals around flues, wall ventilation grills and window lintels.

Loose roof tiles or damaged roofing with no sarking may provide leakage to exterior areas. Roof gutters may hold dust/residue in this regard.

Tween wall vertical cavities accessible from ceiling space may have been intentionally filled or will contain dust/residue from loose fill material. Sub-floor areas open to those cavities may also be contaminated, with settled dust occurring at pipe penetrations through walls to exterior.

A previous remediation process whereby the material was pumped out is unlikely to have removed 100% of the material. Dust/residue may remain, particularly below non-ACM insulation that may have been installed later.