Home / Electrical Infrastructure

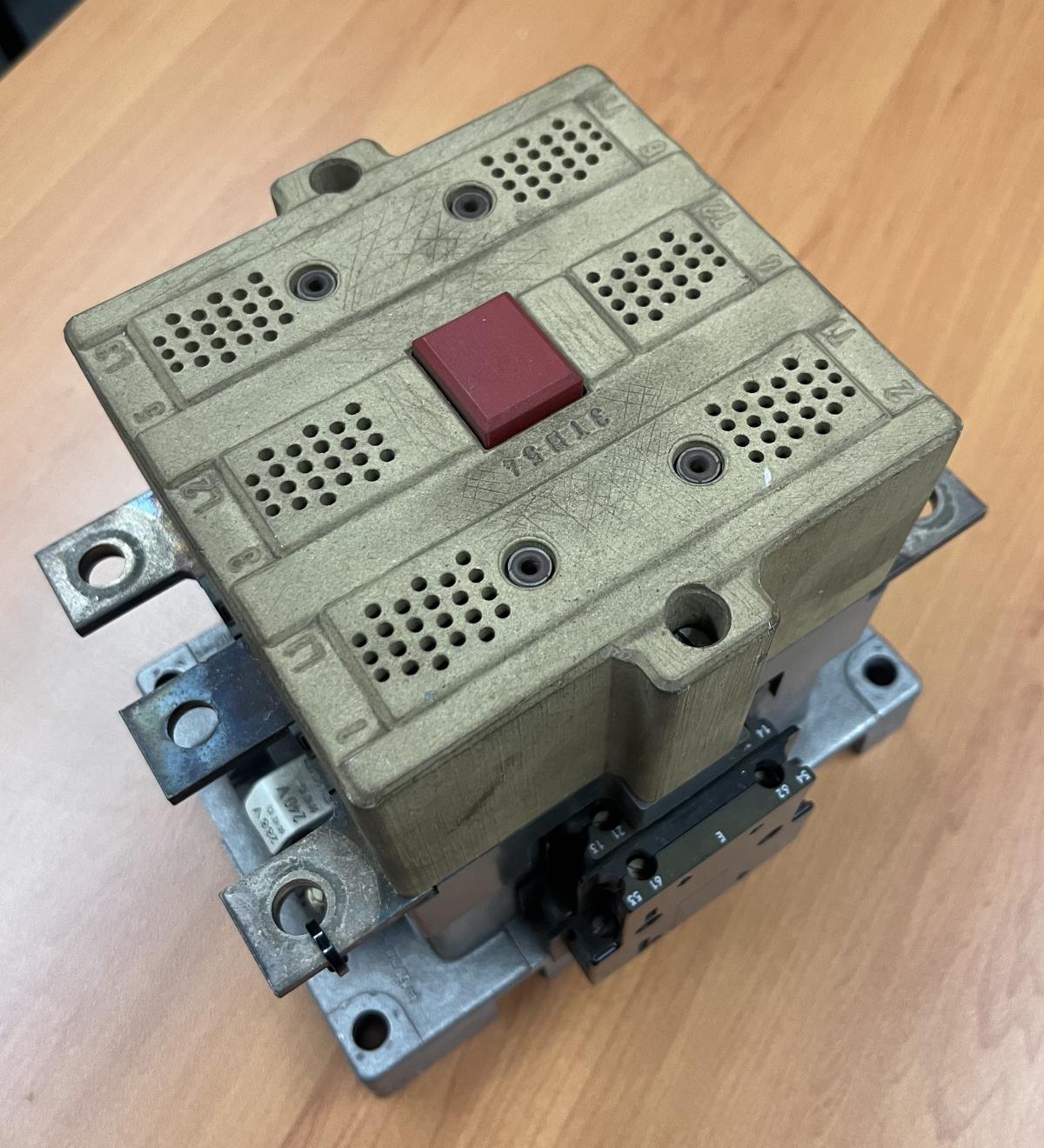

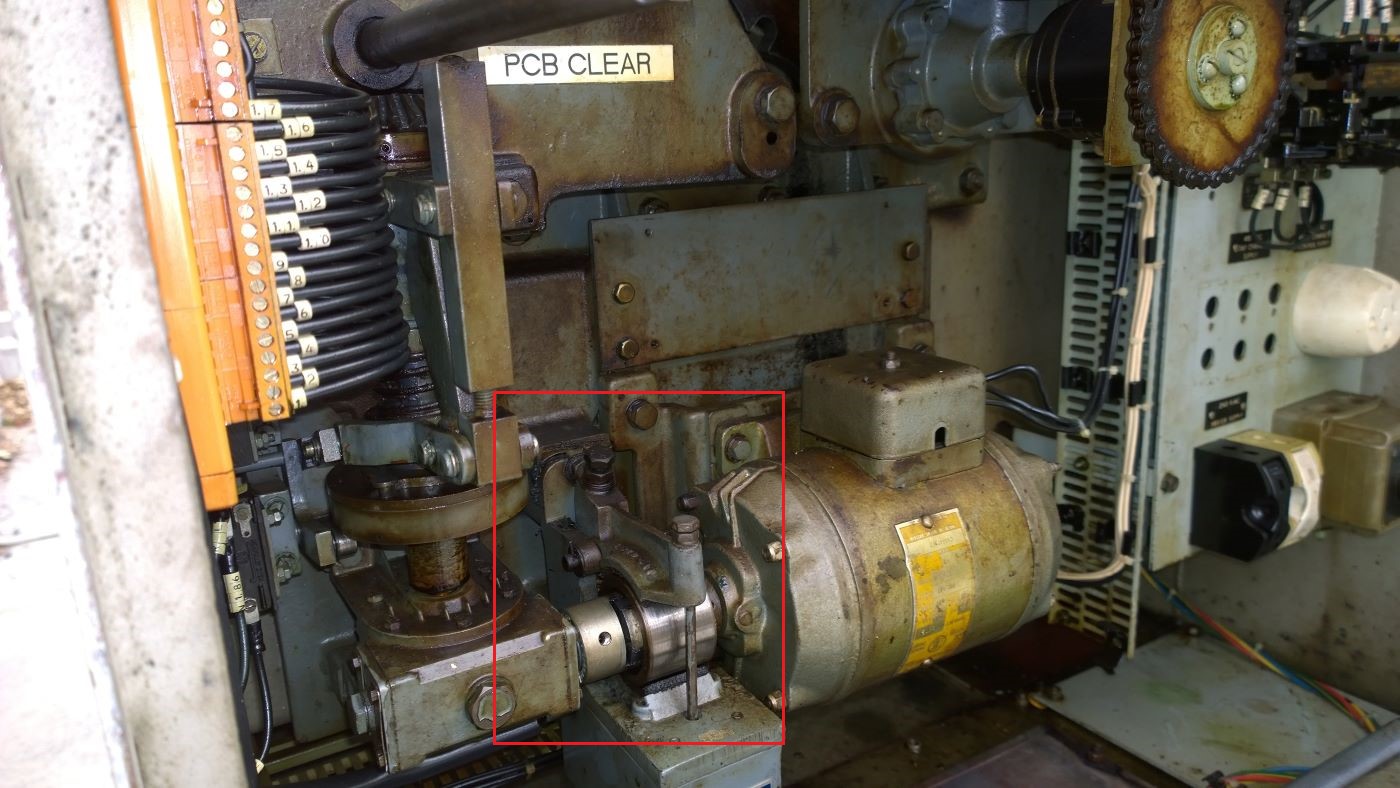

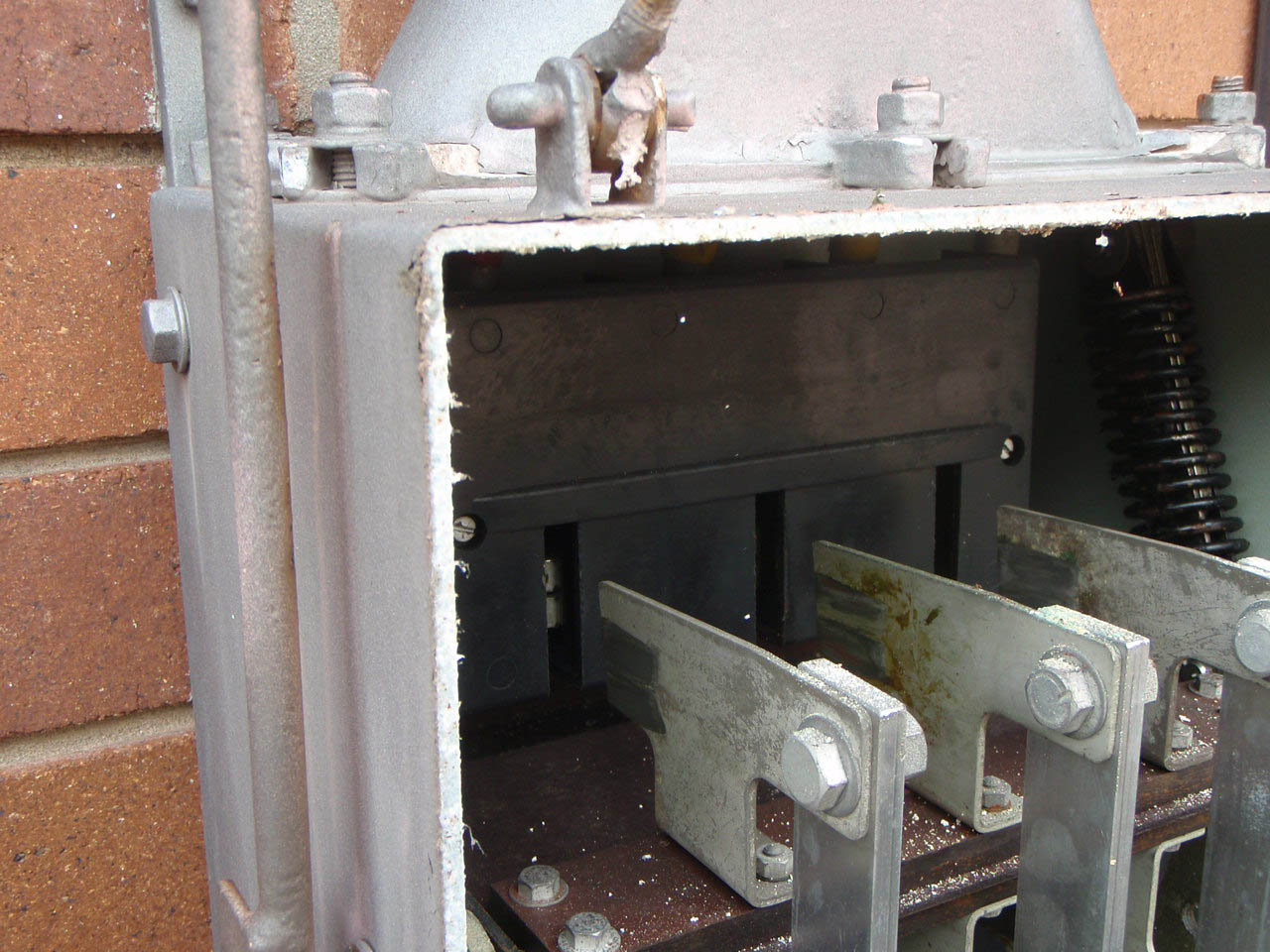

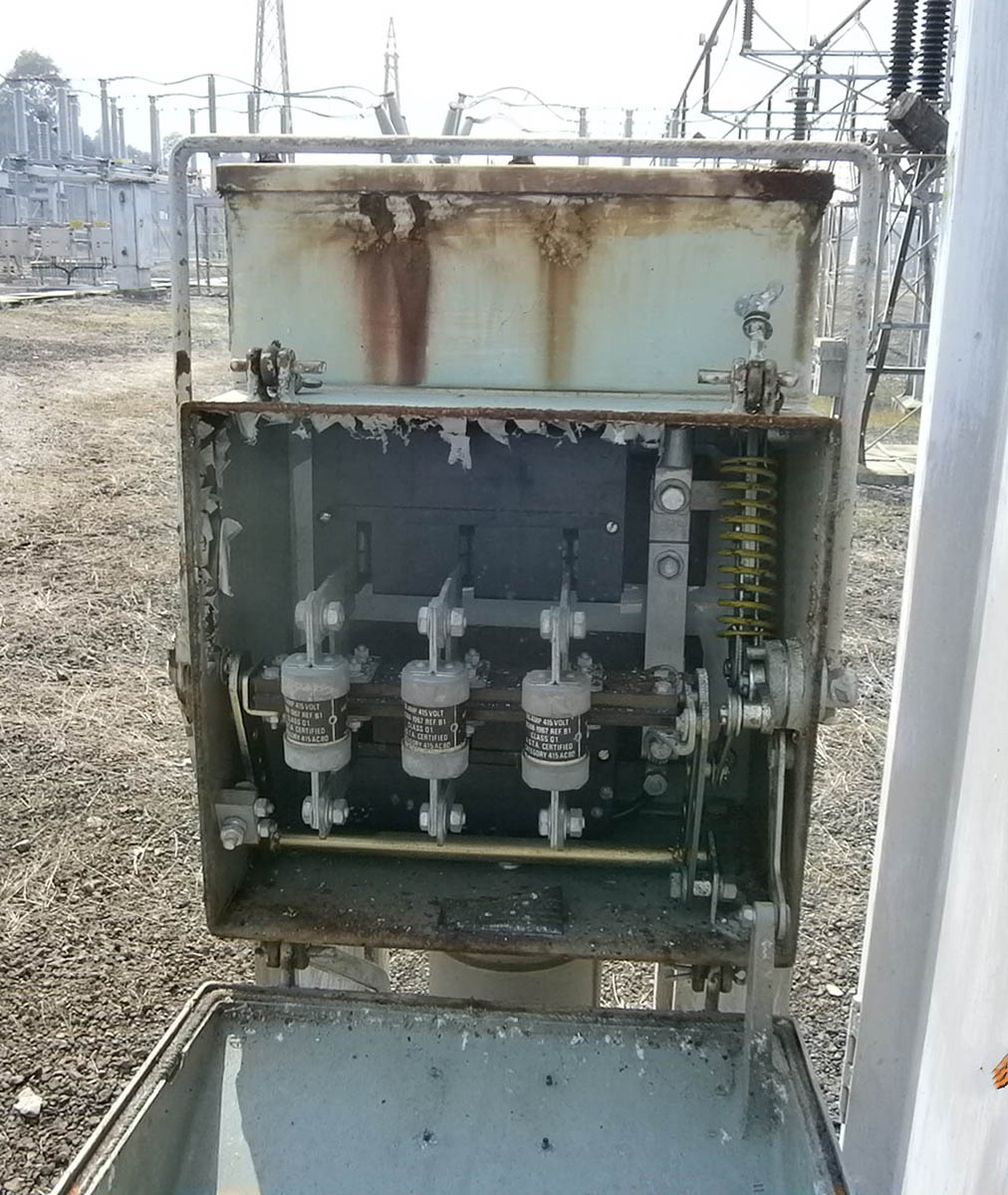

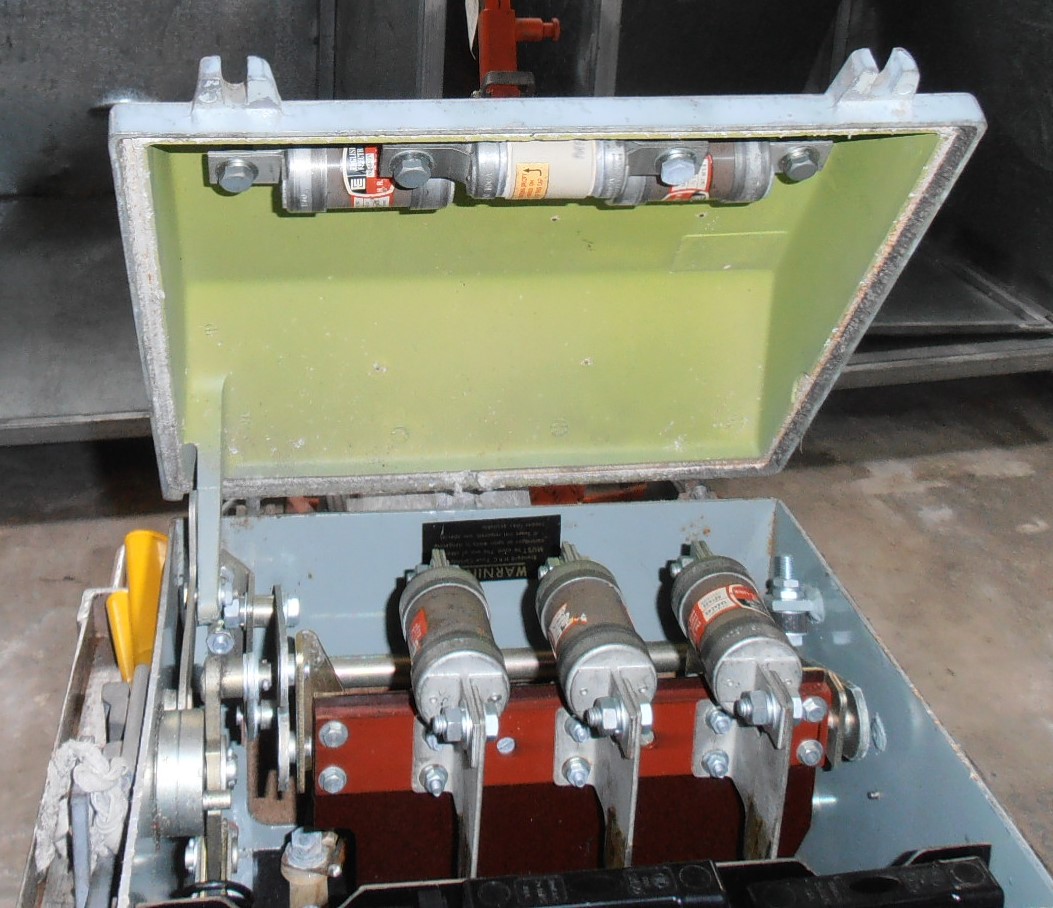

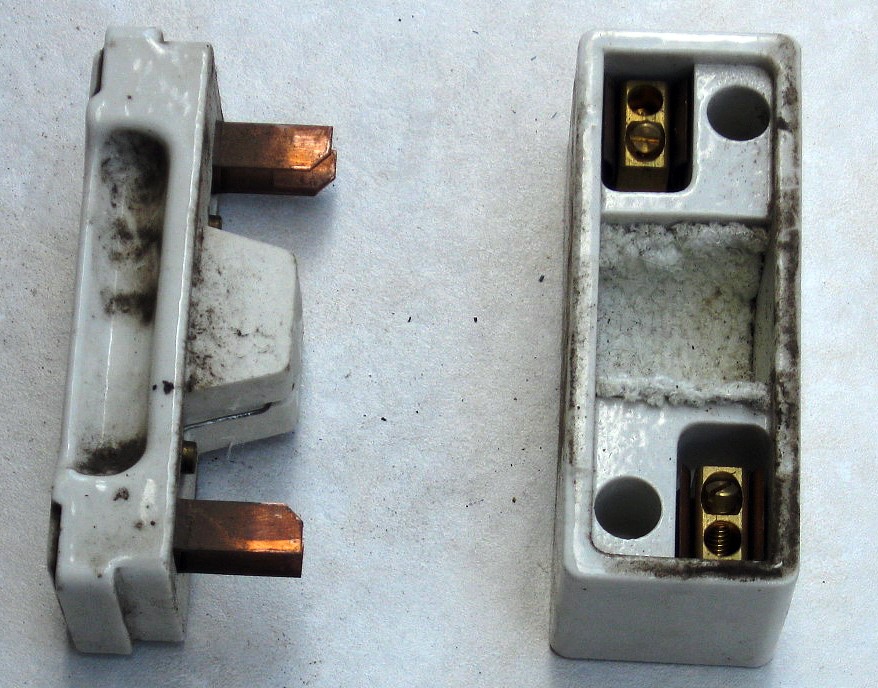

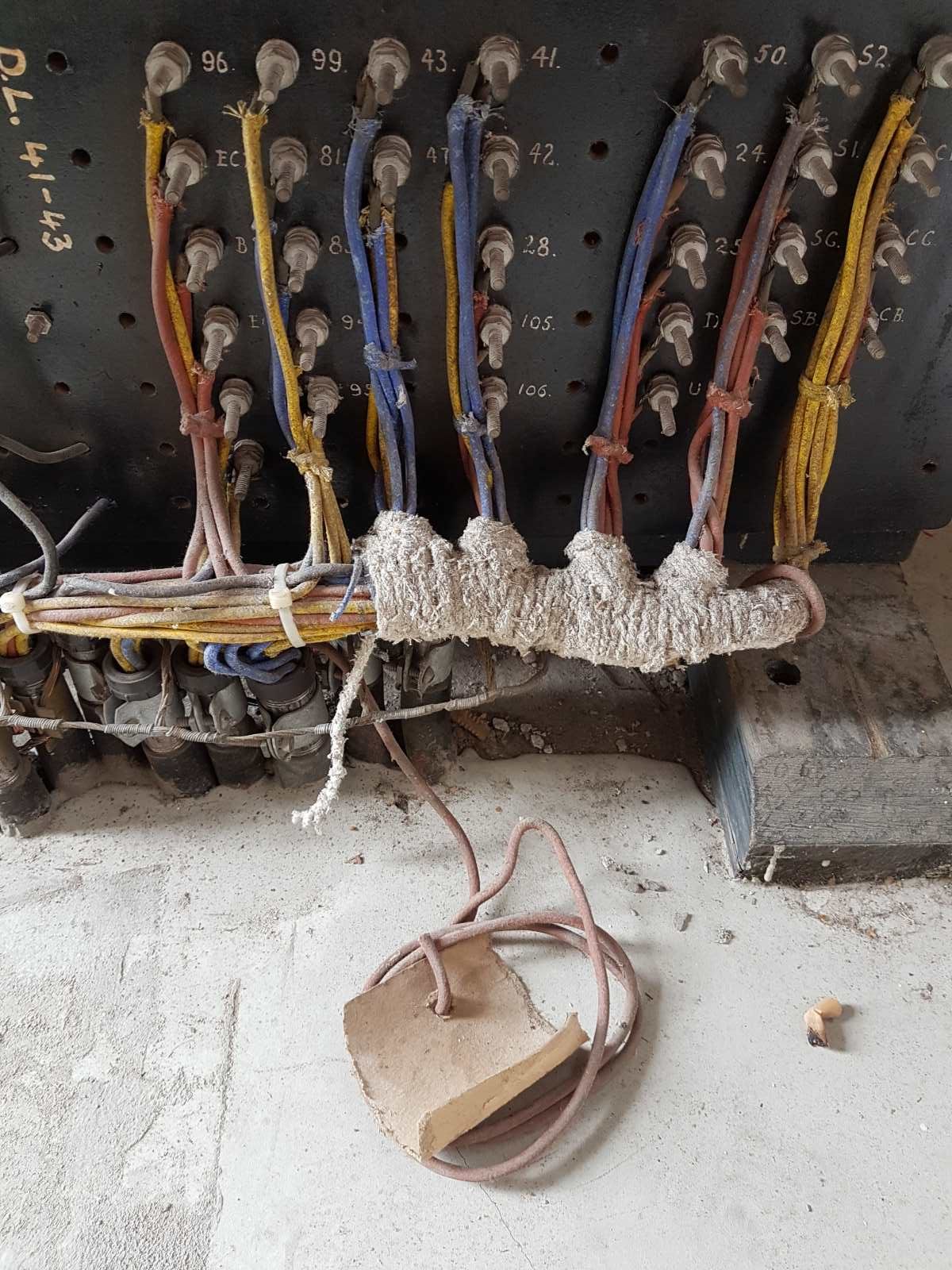

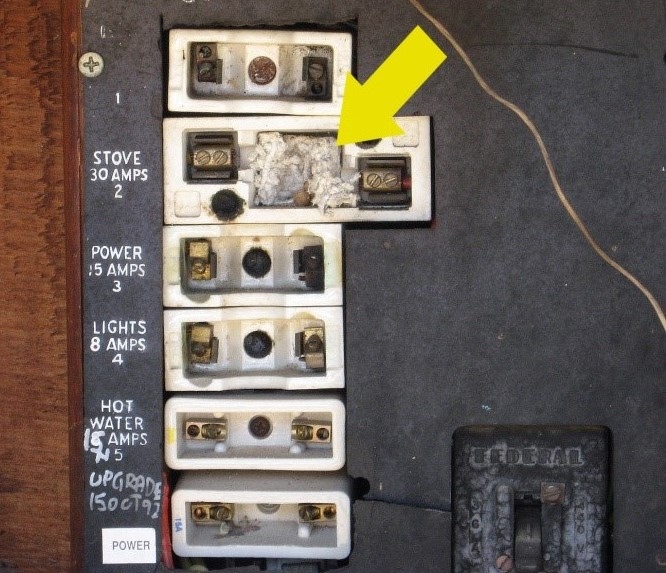

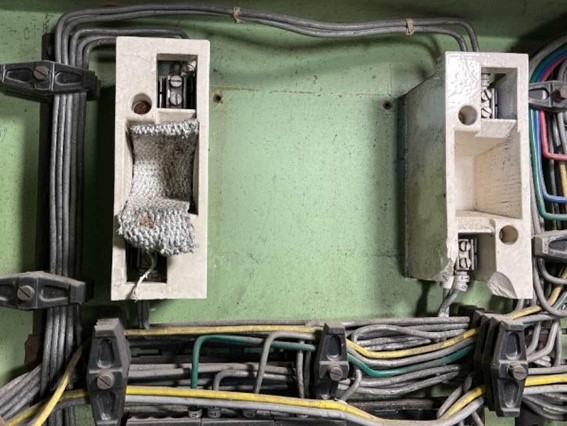

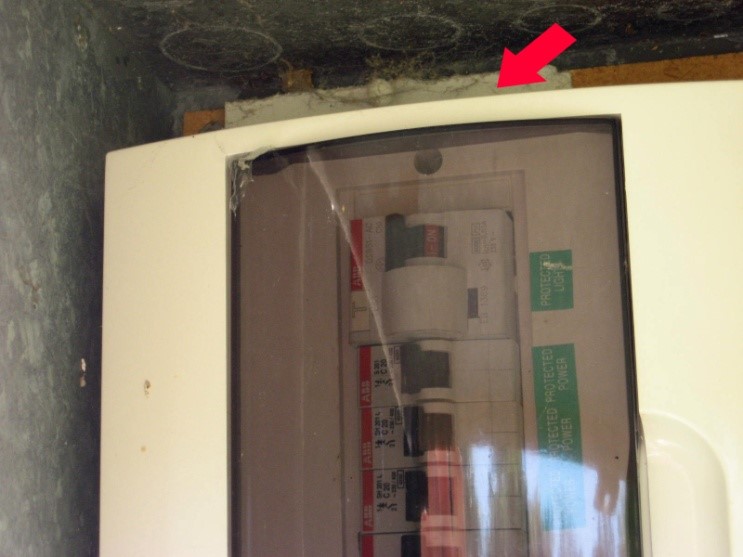

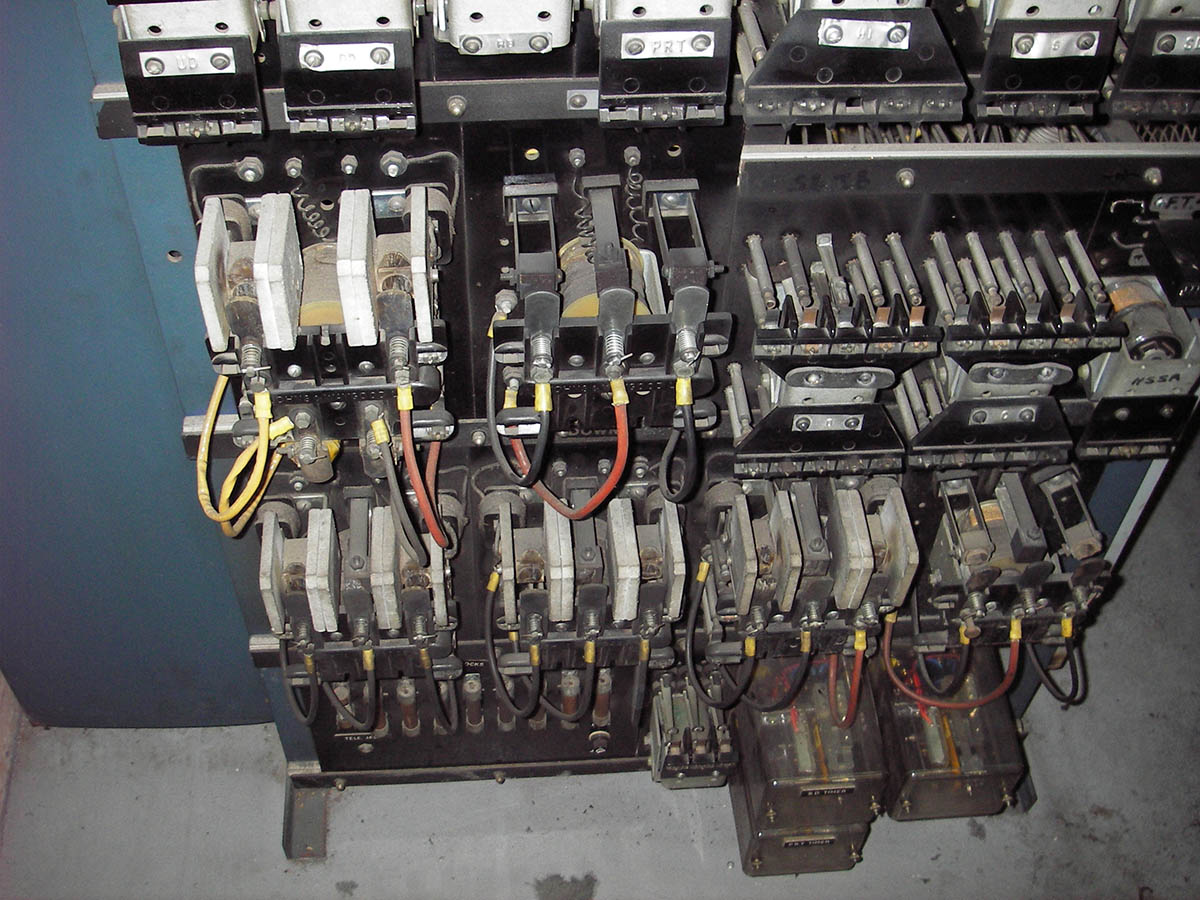

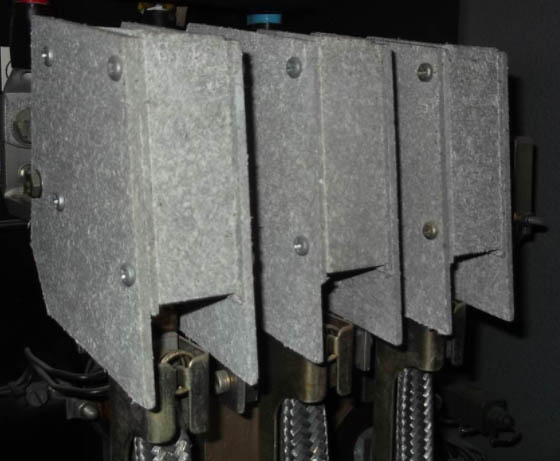

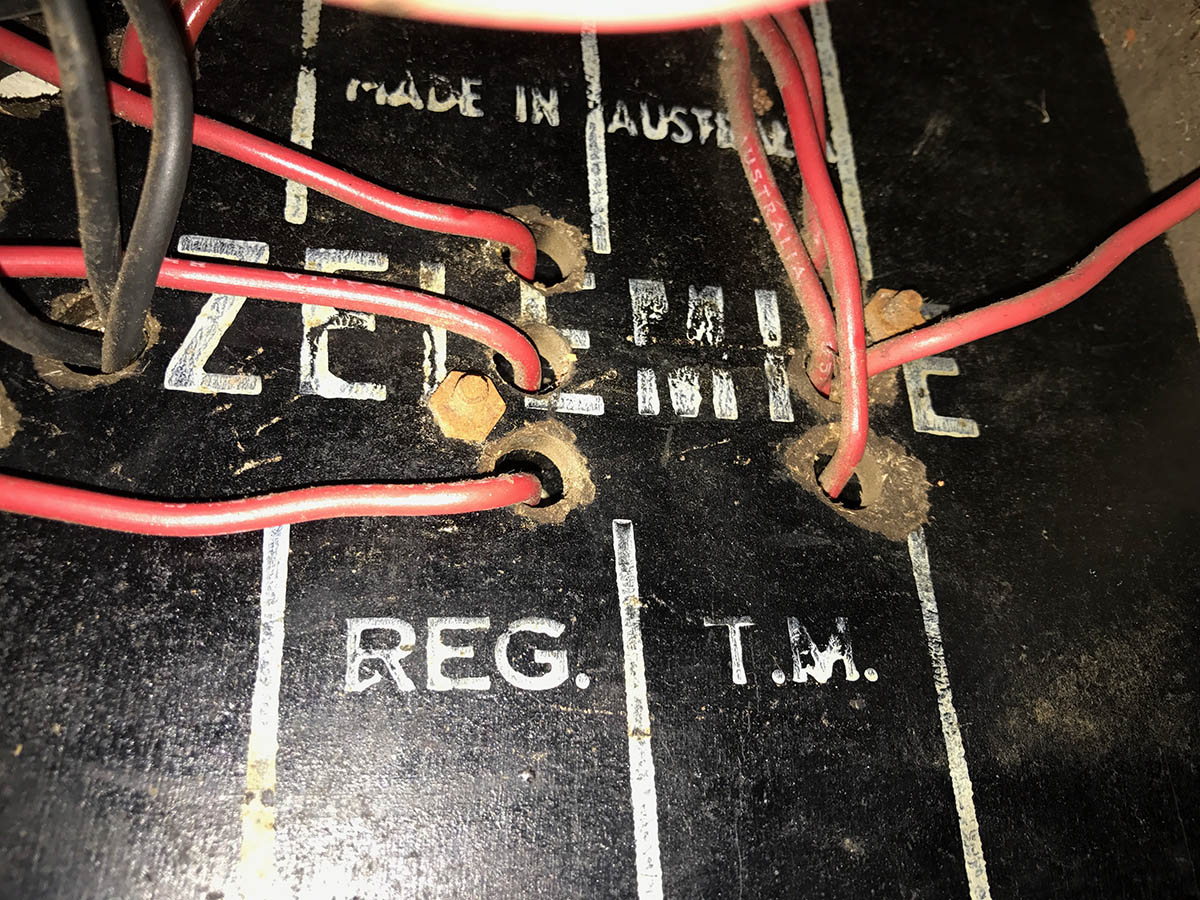

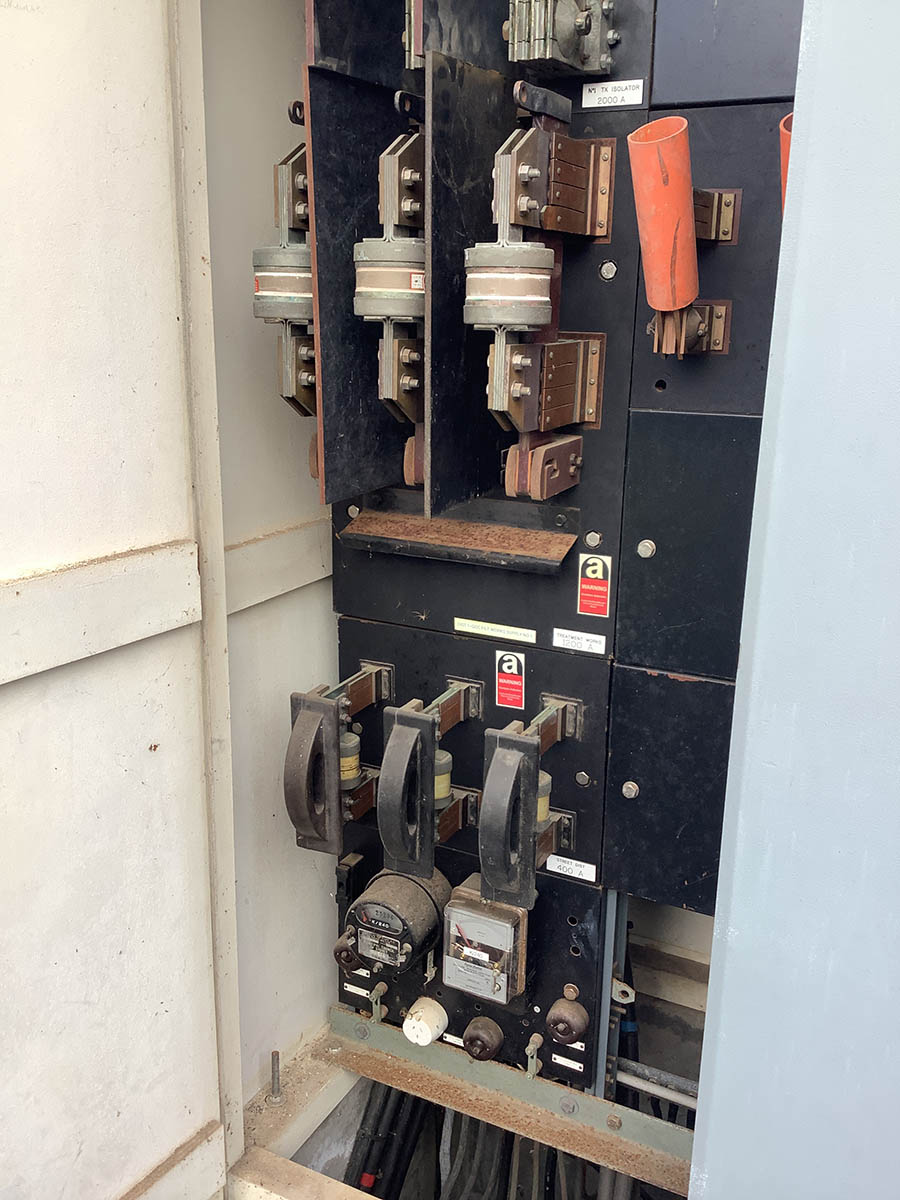

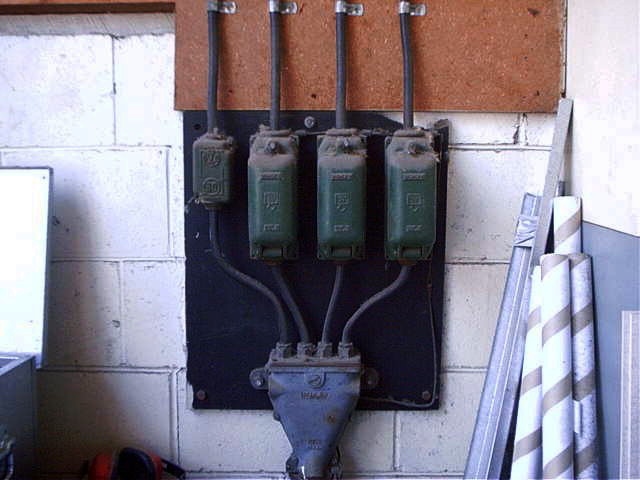

Electrical contactor frames with asbestos

Description

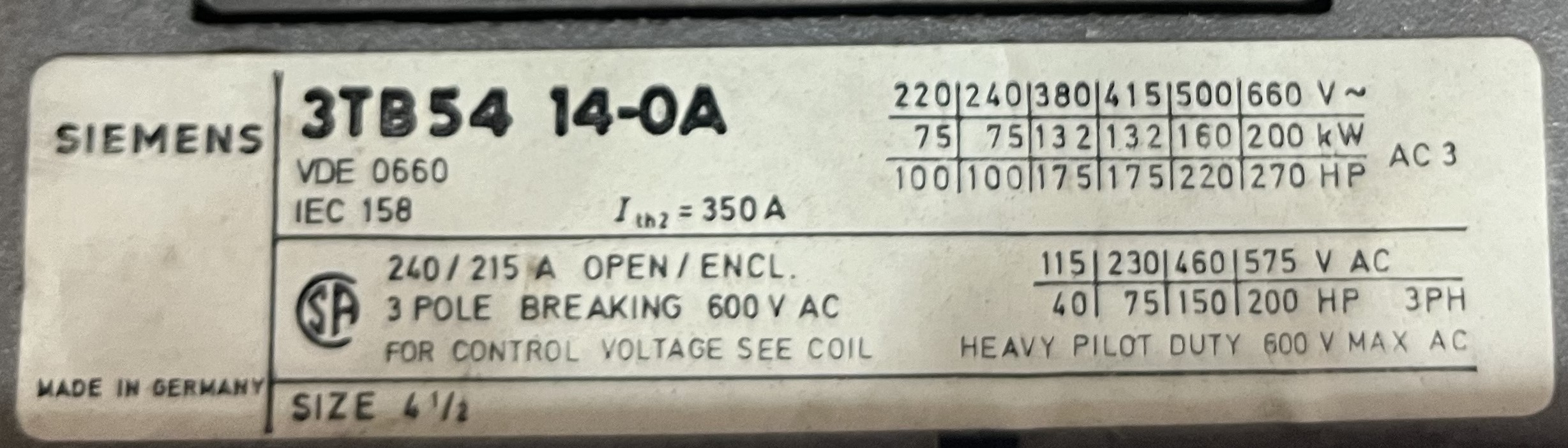

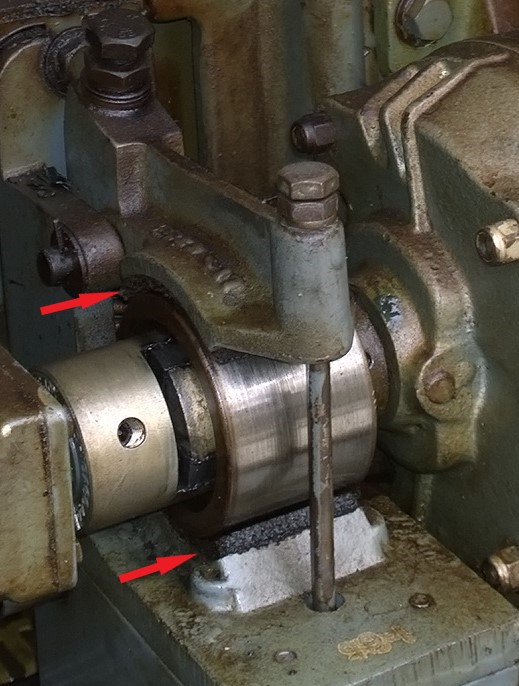

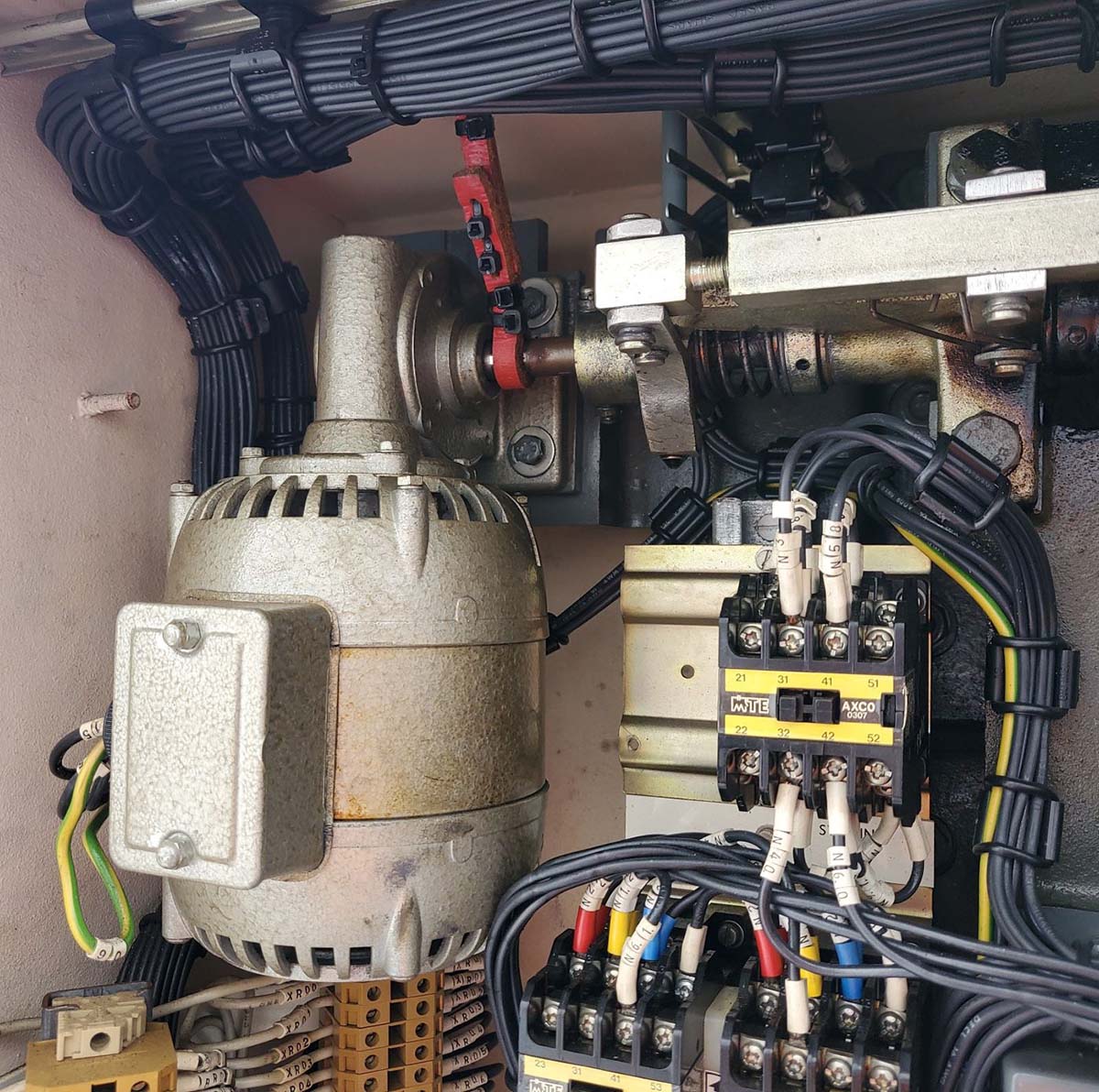

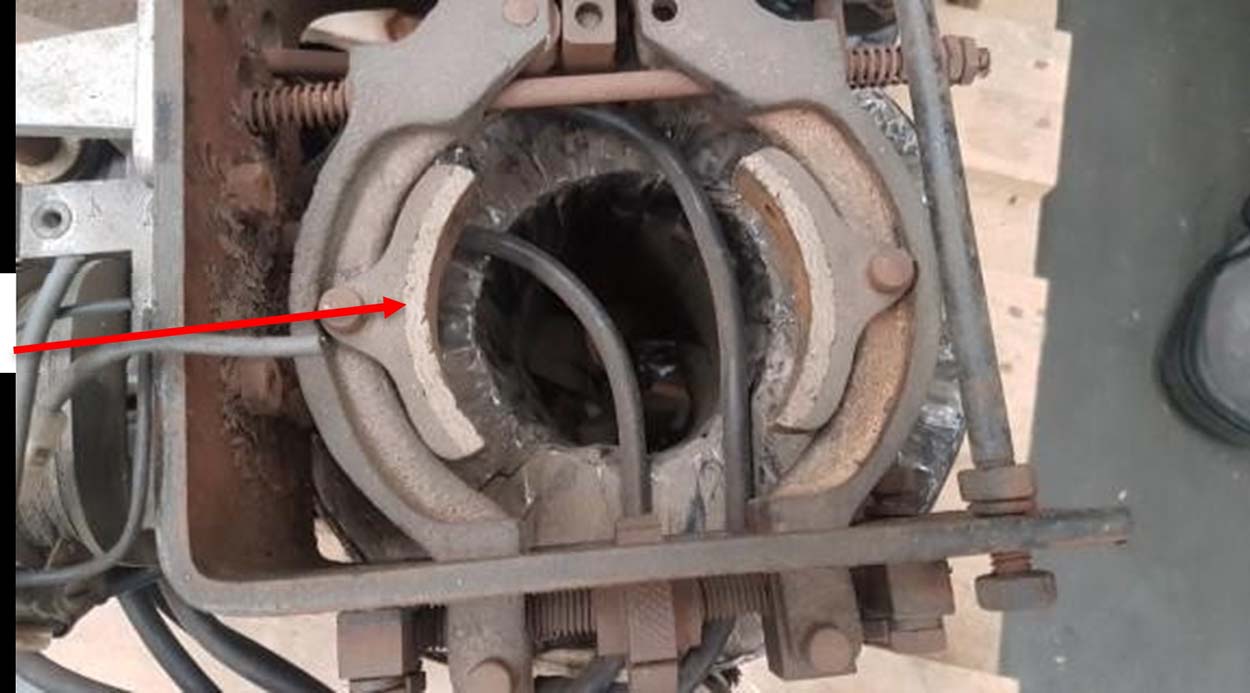

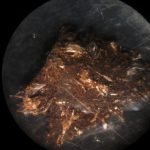

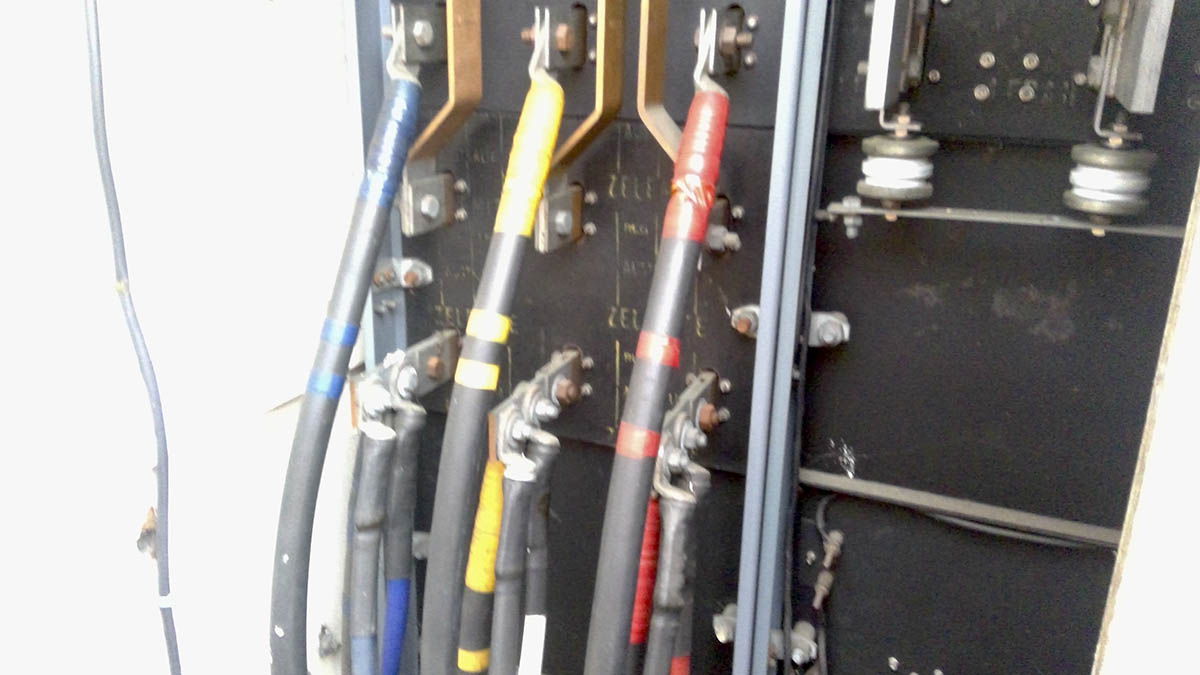

Industrial contactors (often used for switching motor starters) produced by Siemens Germany, prior to 1993. The frame structure is a grey coloured thermoset plastic (Bakelite-type) material containing chrysotile asbestos.

Certain contactors produced up to 1982 contained asbestos in thermoset plastic parts. No asbestos is said to have been used in production since 1985 (Siemens Germany).

The affected units included frame sizes:

- 3TA

- 3TB (first generation)

- 3TB52

- 3TB53

- 3TB54

- 3TB55

- 3TB56

- 3TB57

- 3TB58

- 3TC (first generation)

The Frames within 3TB40-43 to 3TB51 range is said not to contain asbestos. Although, a 3TB50 in Australia was sampled and tested and found to contain chrysotile asbestos.

Brands/products

Siemens

Years of production/use

Prior to 1993

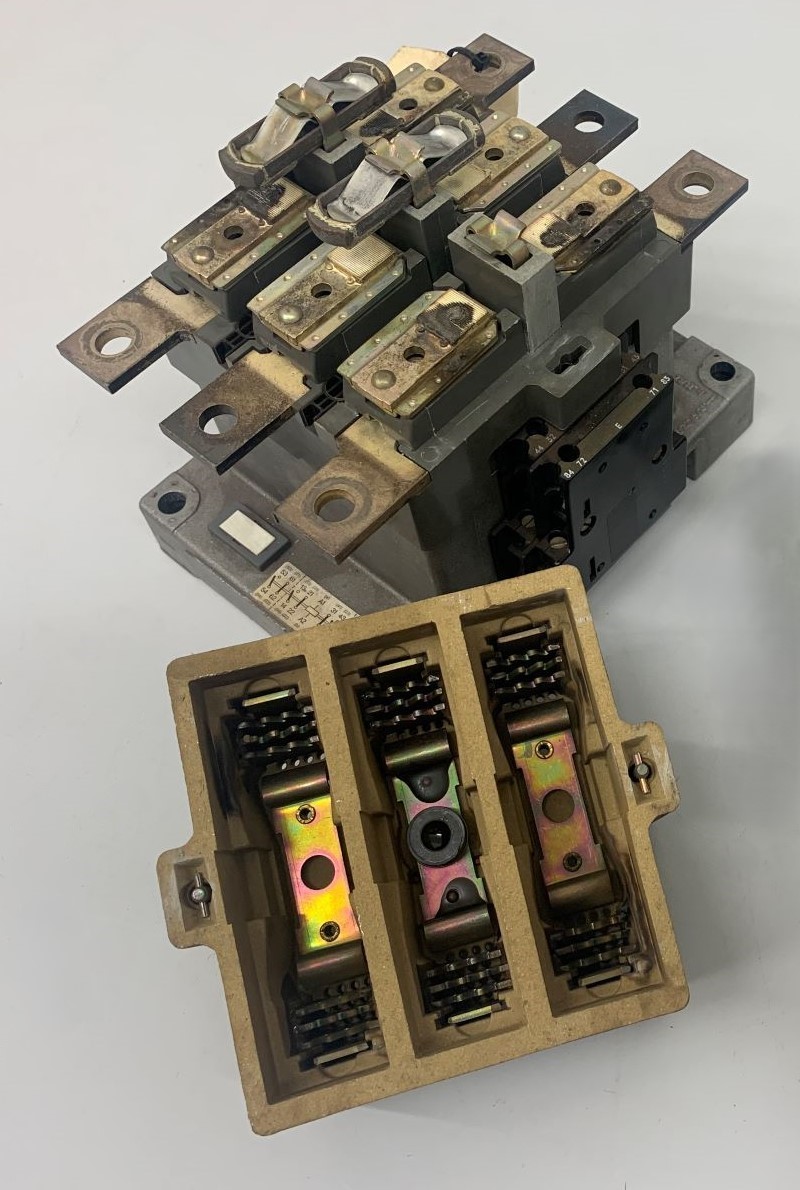

These frame designs are still in use with a current spare component market available which means the older frame can be updated with replaceable components. There are many older frames across the 3TA/B/C range available for sale in online market sites.

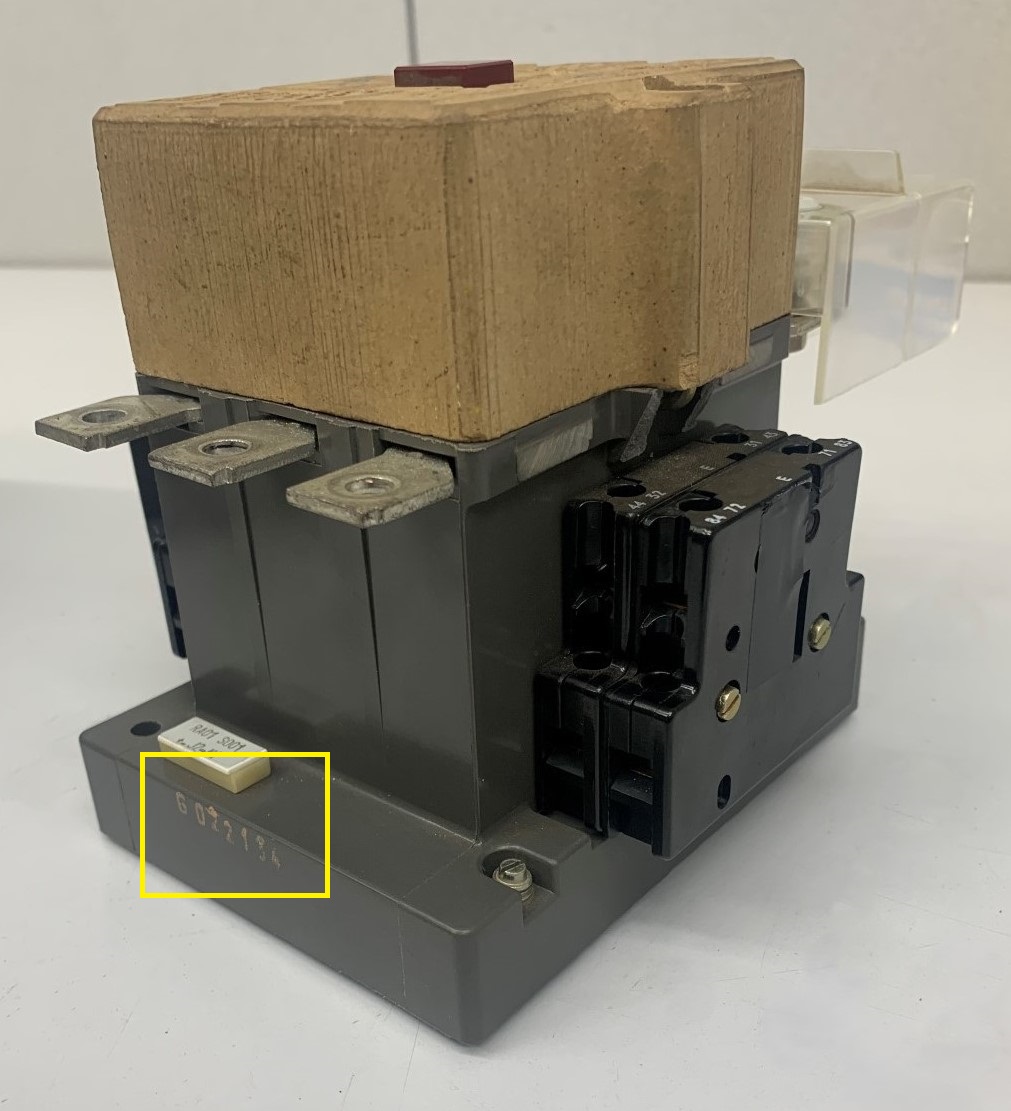

The use of asbestos was banned in Germany in 1993. The manufacture date can be identified buy a G followed by a 6-digit combination of numbers (G mark) on the frame, the first two indicating the year of manufacture. G marks are not always present across all models. For safe assessment, units produced prior to 1993 should be regarded as a risk for asbestos content until proven otherwise.

Residential uses

N/a

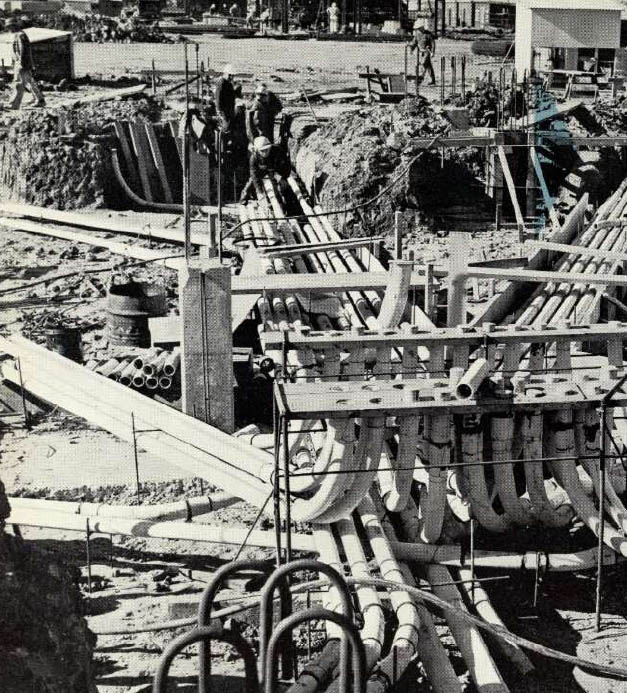

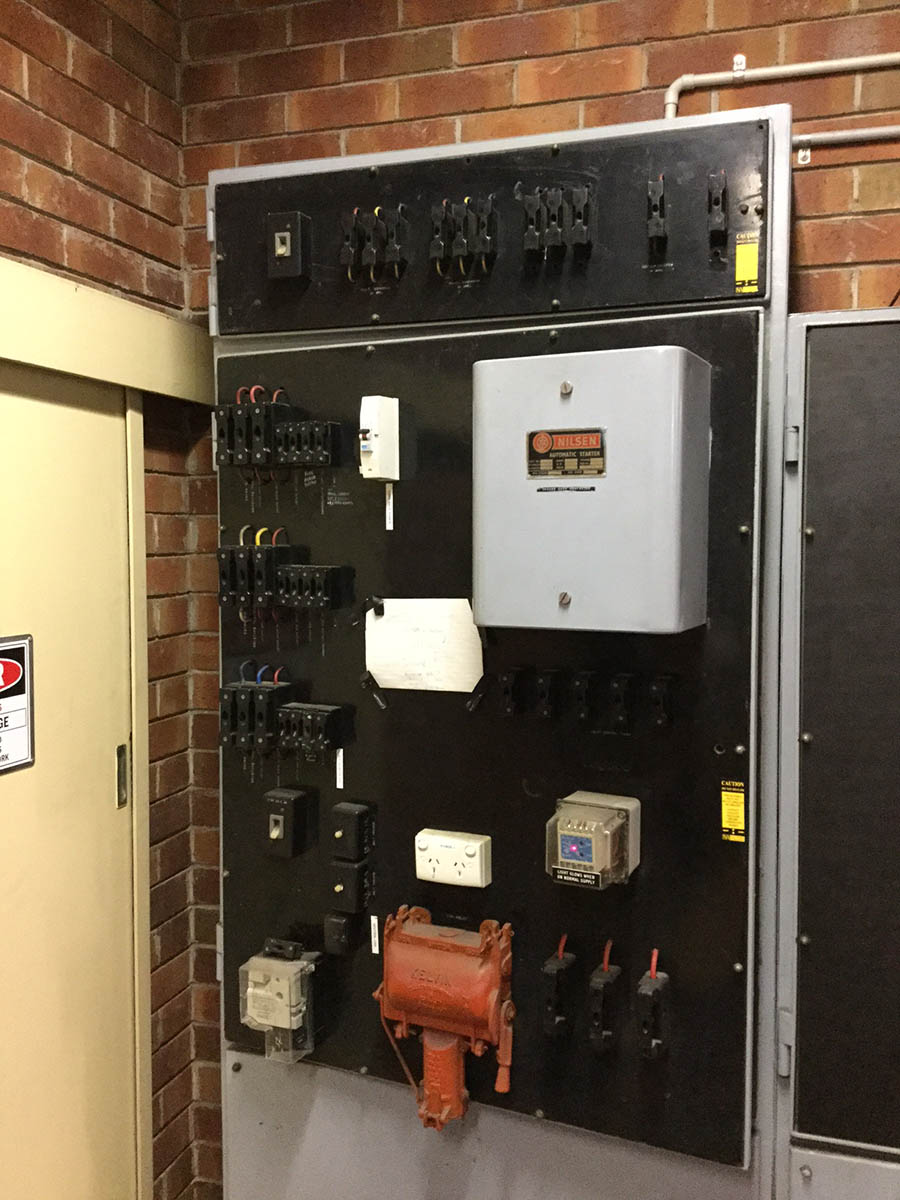

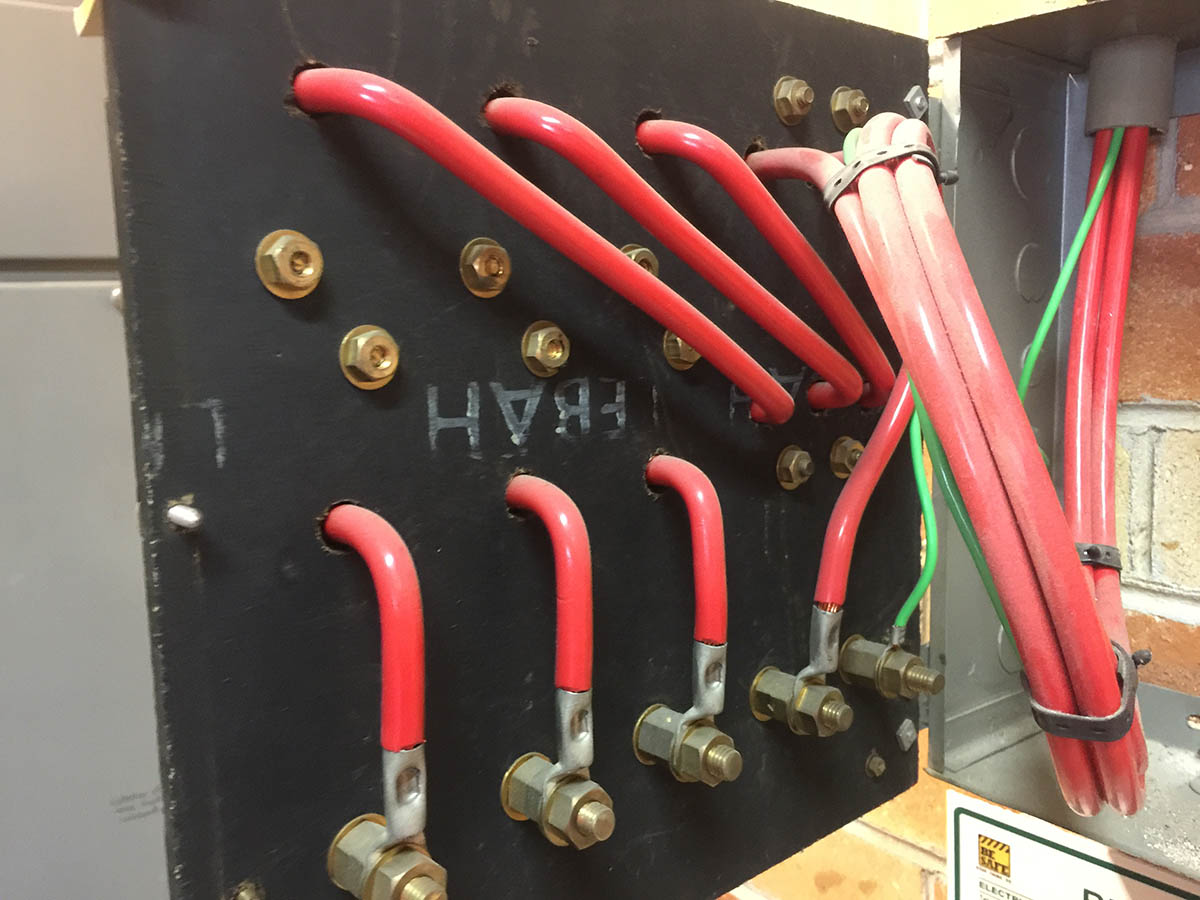

Industrial uses

- Large, fixed plant/infrastructure applications requiring continuous high voltage applications.

- Maritime vessels/platforms

- Railway and transport

- Power stations

Be aware

The housing may suffer slight damage, particularly in high voltage industrial use, when the units trip under heavy voltage load, causing material debris. This may be a result of age and repeated use.