Home / Building Structures & Components / Walls / Page 2

Asbestos cement flat sheeting – interior

Description

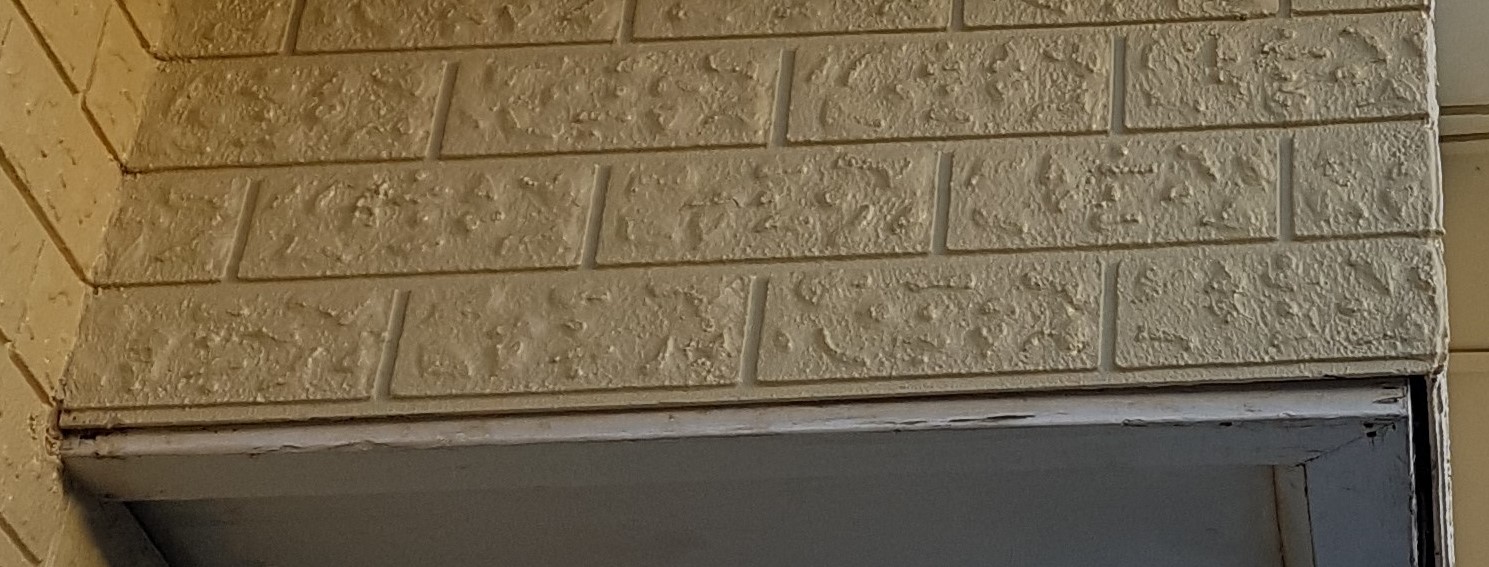

Surface appearance generally like plasterboard.

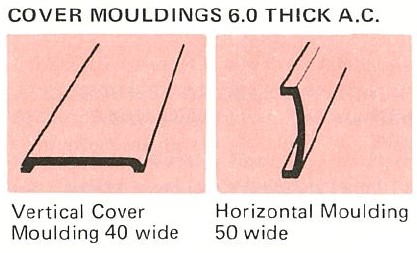

Sheet jointing may be covered with obtrusive AC cover moulding, wooden battens, or ‘Anaglypta’ paper strips, before painting. Shear point nails used for fixing in place – flat heads may be visible.

Villaboard was a water resistant AC sheeting for interior linings behind material such as wall tiles, behind/on top of cupboards and as a wallboard above decorative lining height within bathrooms. Produced with recessed and square edges. First produced by Wunderlich, then CSR still under the Wunderlich brand, and then finally by Hardies. James Hardie manufactures a non-ACM product with the same product name today.

Duracast (1930s) had a rough cast appearance.

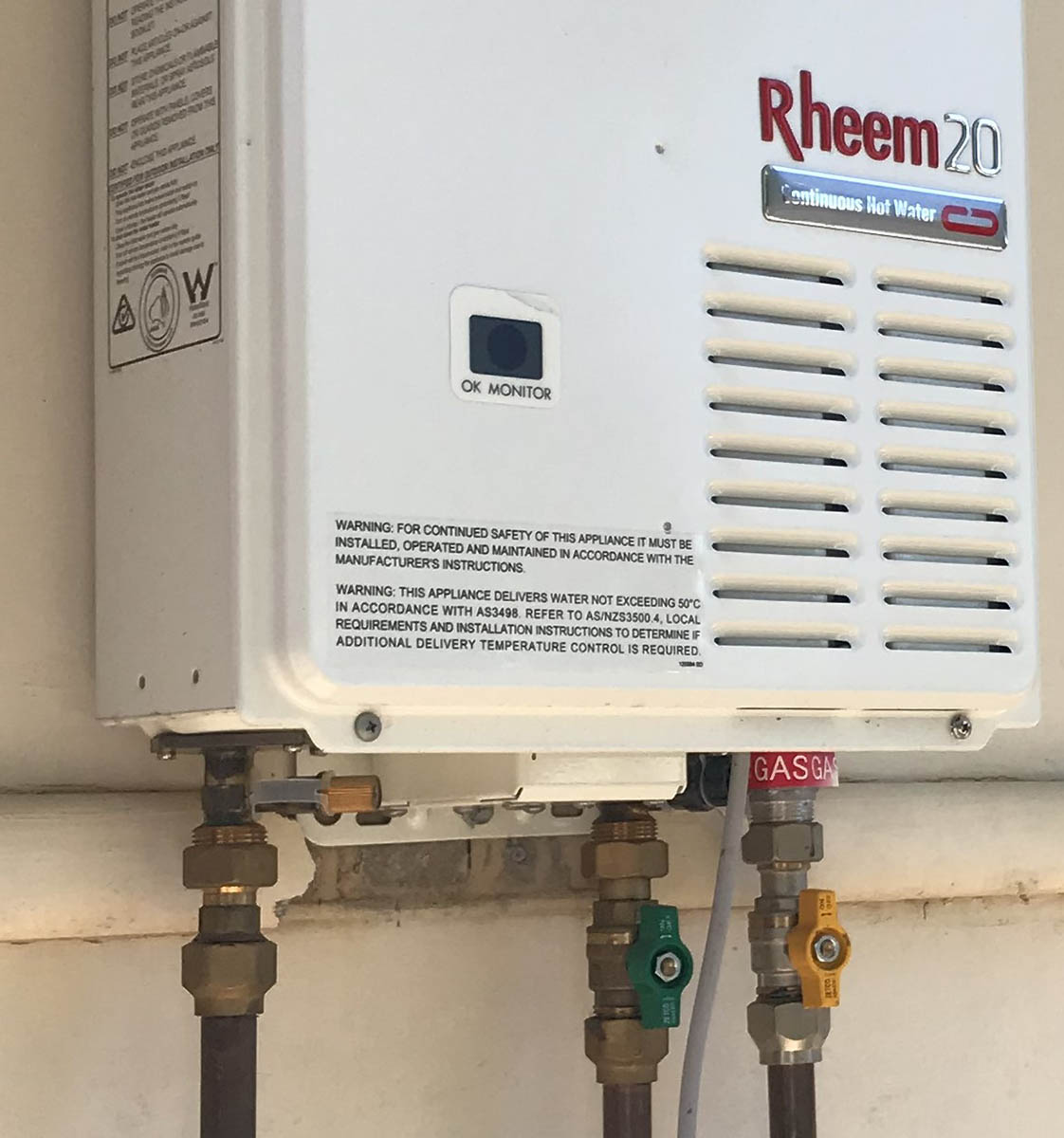

Flat AC sheeting used ad-hoc for providing vertical heat protection behind stoves and heating appliances, as well as shelving.

See also: Compressed flat asbestos cement sheeting.

Years of production/use

Prior to 1990

Brands/products

- Fibrolite

- Fibrock

- Tasbestos

- Hardiflex

- Villaboard

- Durabestos

- Asbestolite

- Wunderflex

- Versilux – sold only in Qld, WA and northern NSW

- Flexboard

- Endurite

- Duracast

Residential uses

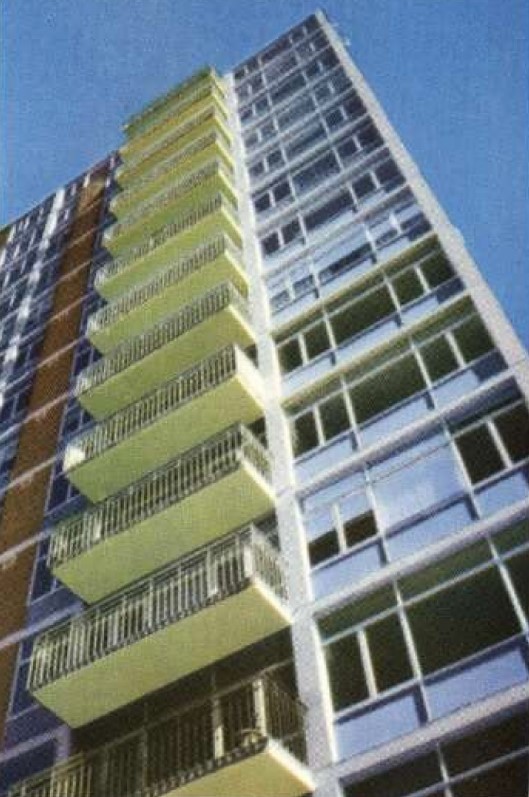

- Houses and other buildings on site.

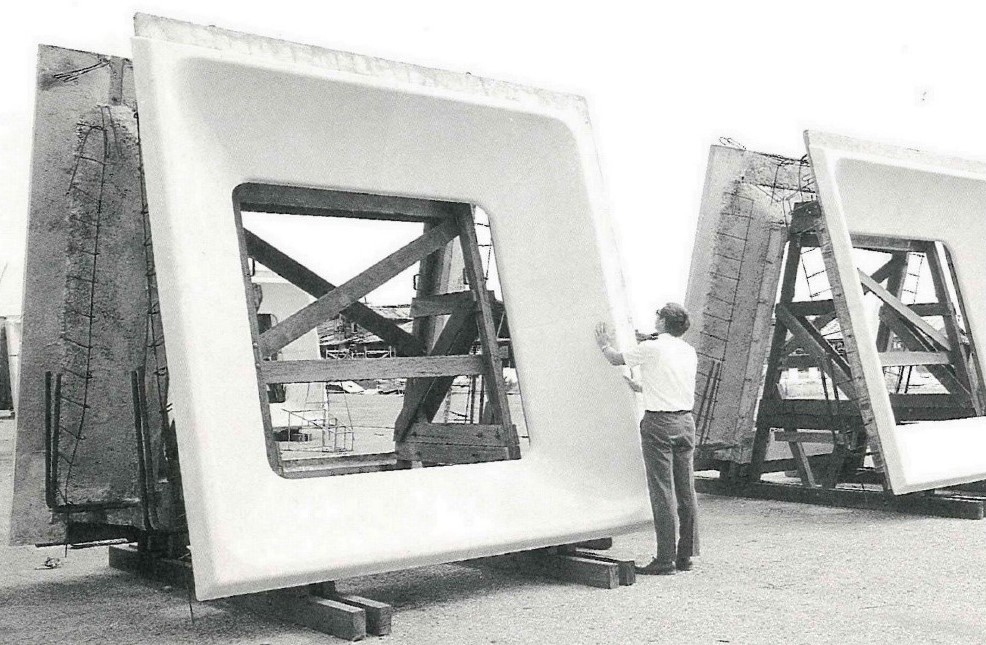

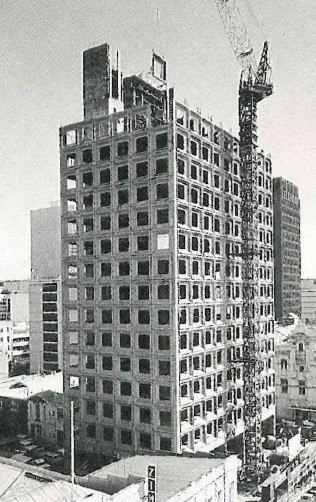

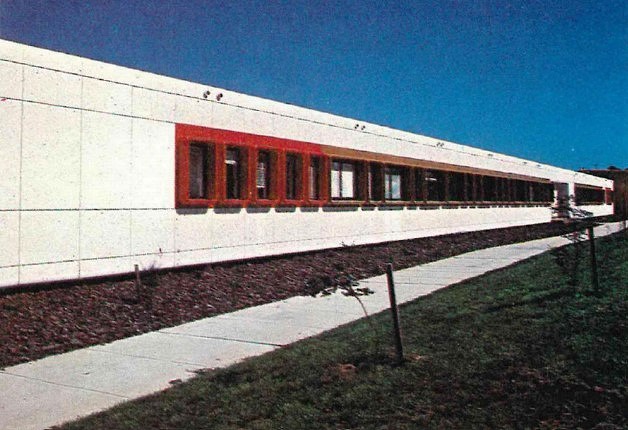

Industrial uses

- Foundries, factories, warehouses, substations, workshops, hospitals, community and government buildings.

- Communal washrooms and changerooms

Be aware

Consider the age of the building. Unless assessed by a professional, 9mm and 12mm thick panels can be mistaken for plasterboard, particularly if painted or wallpapered.

When cutting, drilling or demolishing:

- Cut edges may expose fibres.

- Original AC sheeting may be left in place for additional insulation, with non-ACM panels or tiles attached over the top.

- May have been intentionally used as an underlining sheet for ceramic tiling.

- May have been used as an underlay for flooring such as tiles, linoleum or asbestos containing vinyl flooring.