Home / Building Structures & Components / Walls

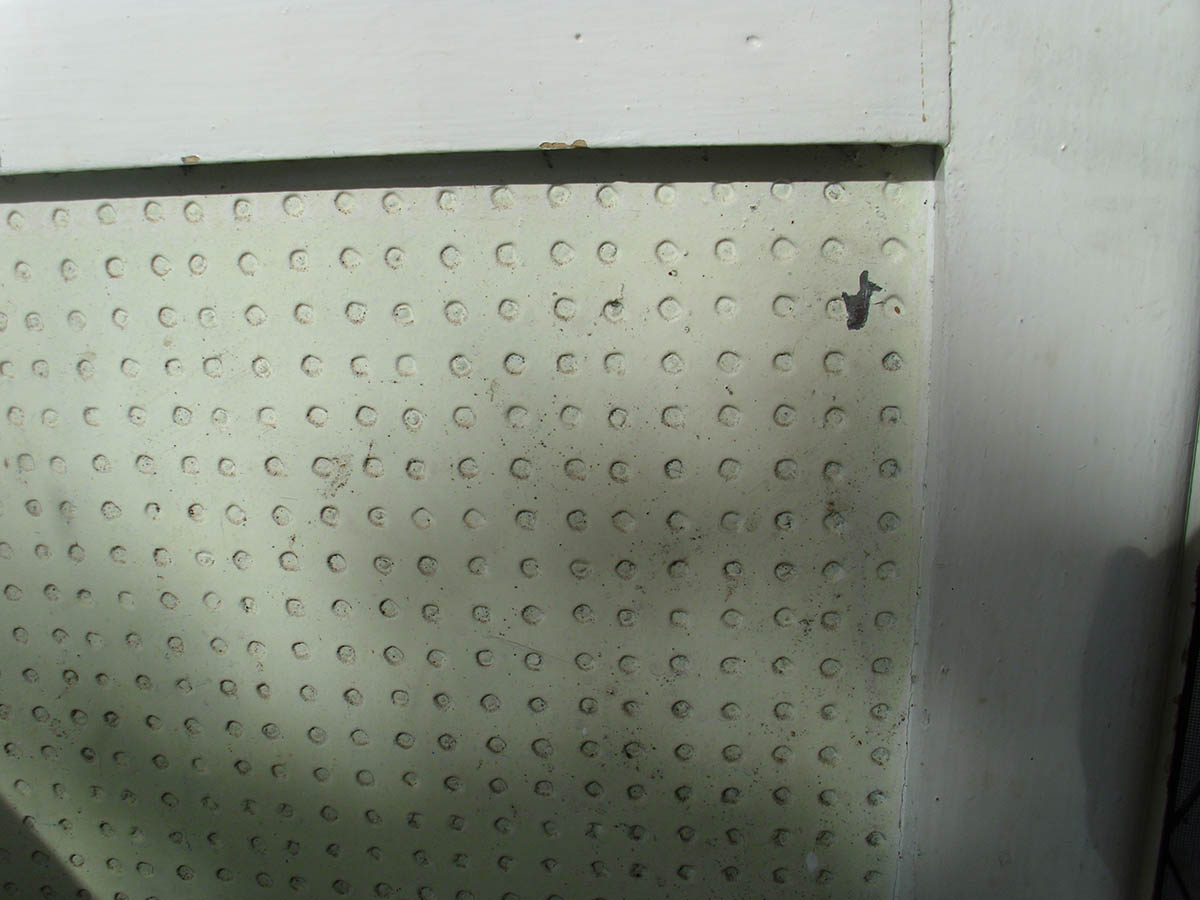

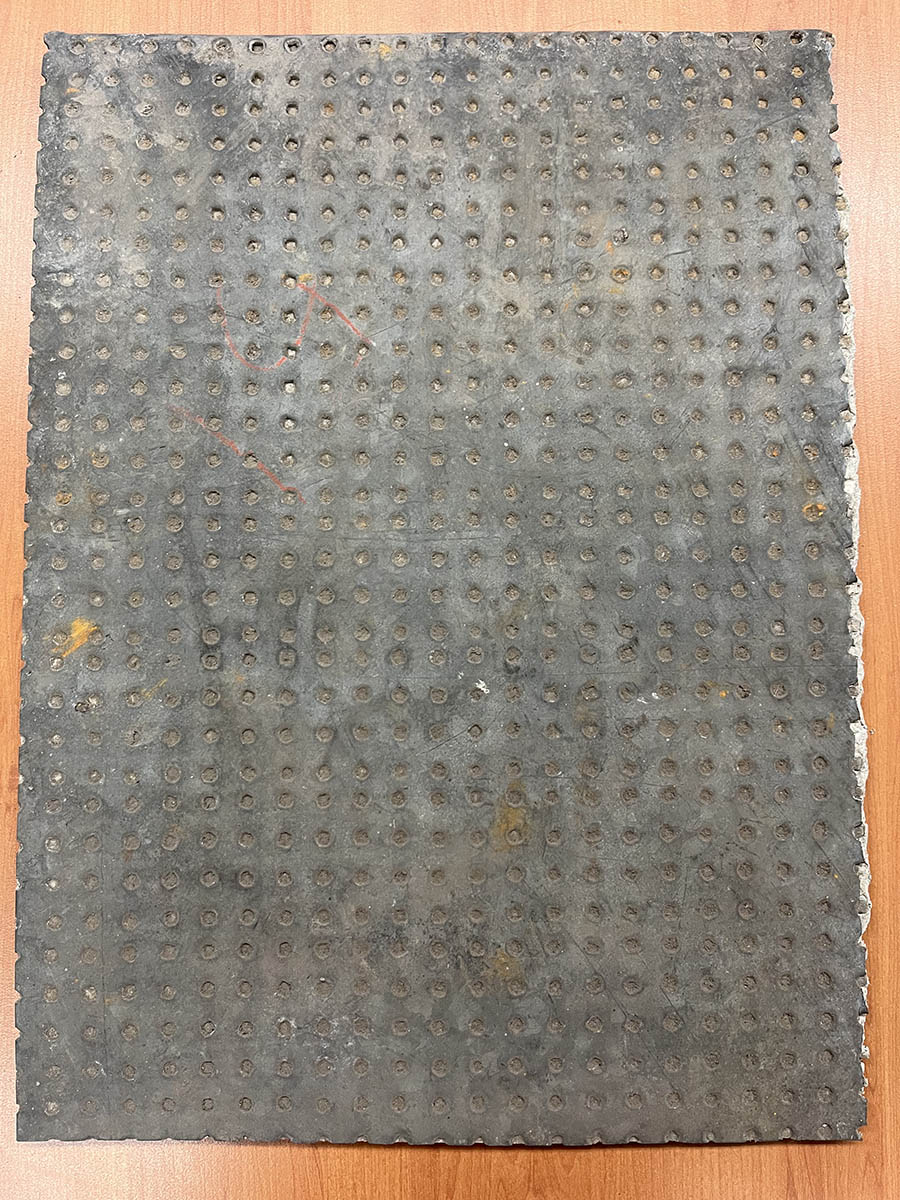

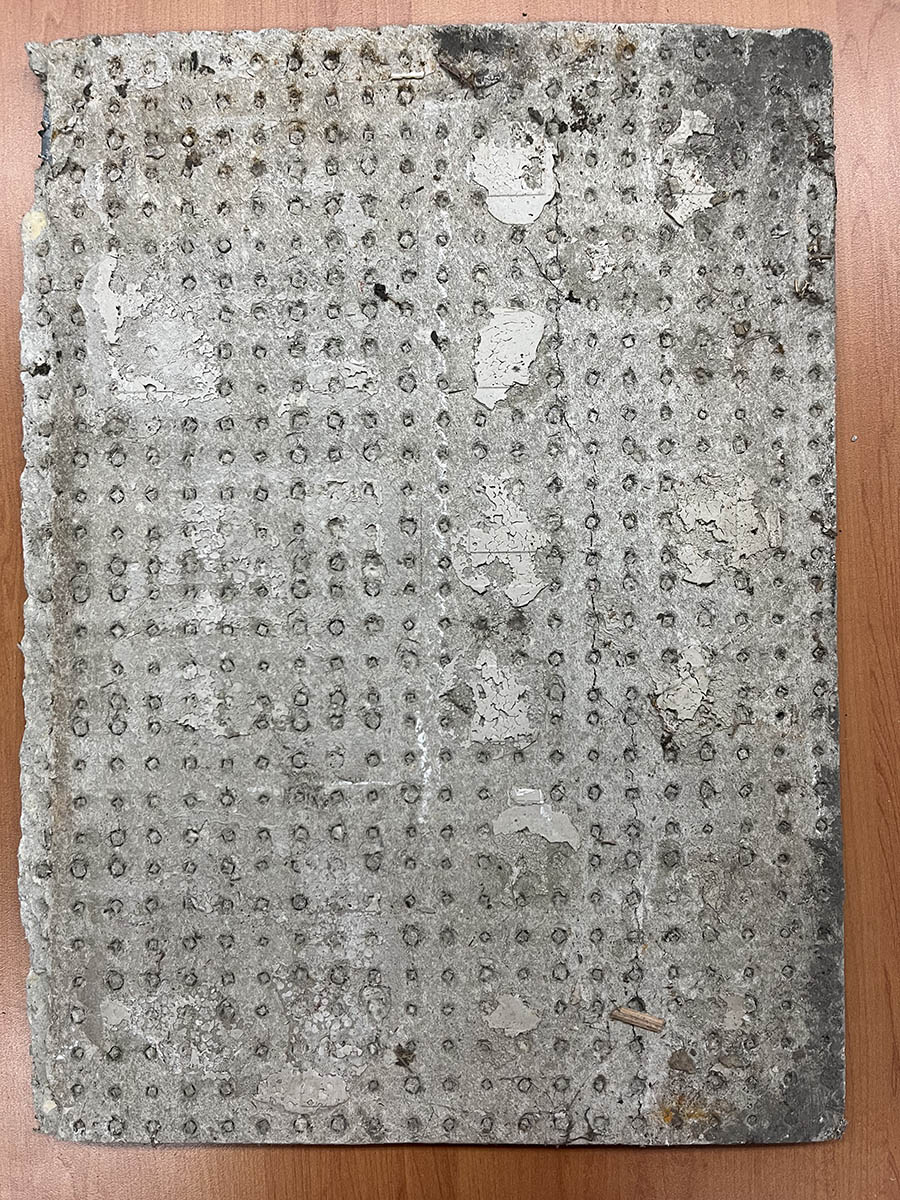

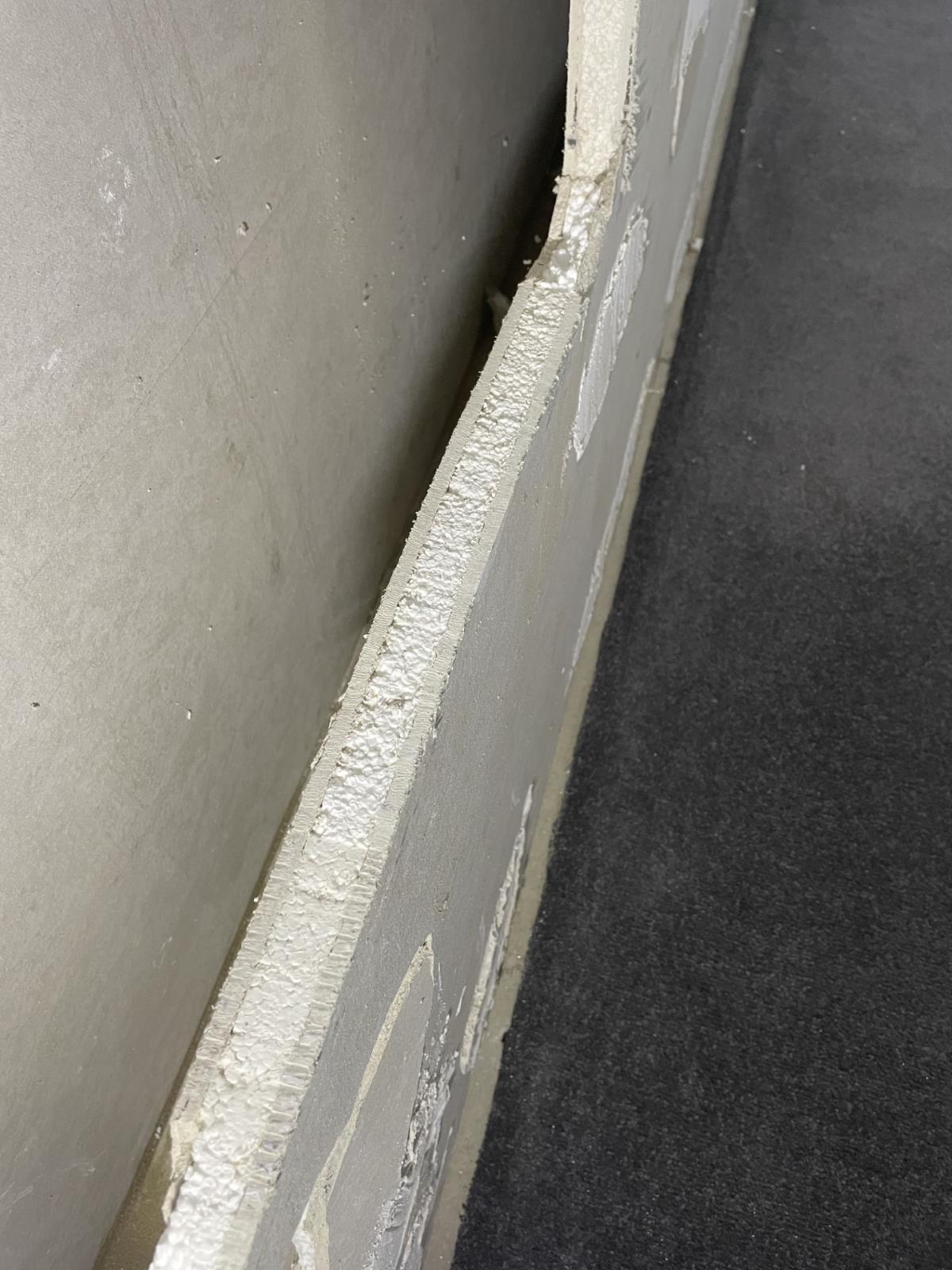

Timber faced asbestos cement sheeting

Description

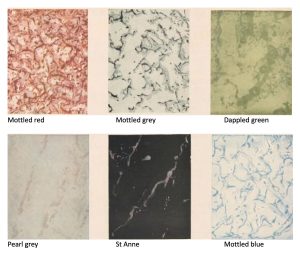

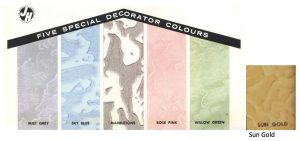

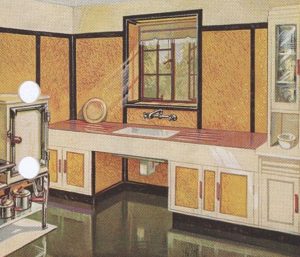

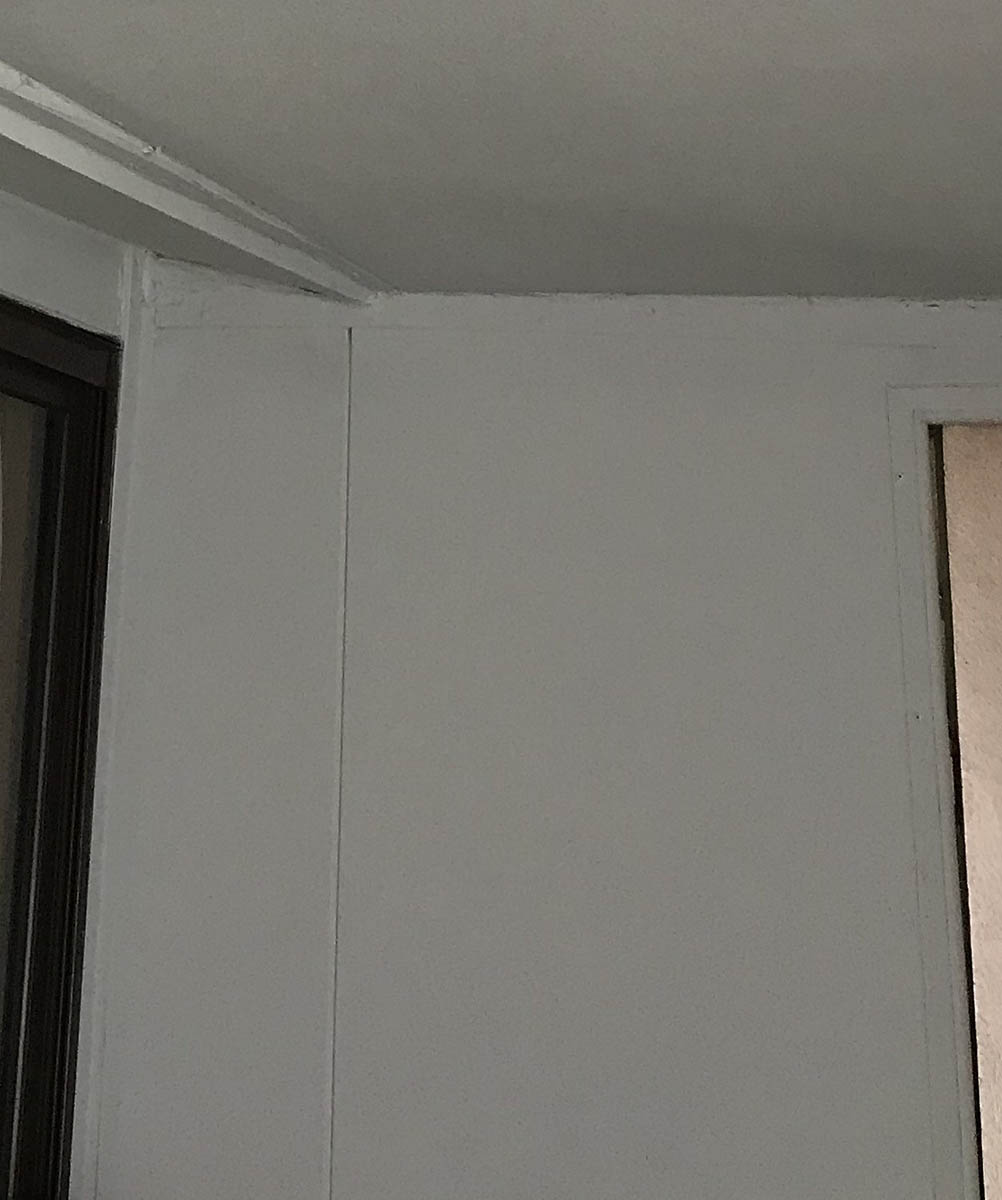

AC sheeting with actual timber or imitation timber veneer on one face.

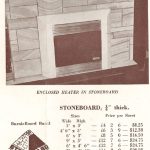

Used as an aesthetic enhancement for interior areas. Promoted as fire retardant, and so recommended for use around fireplaces.

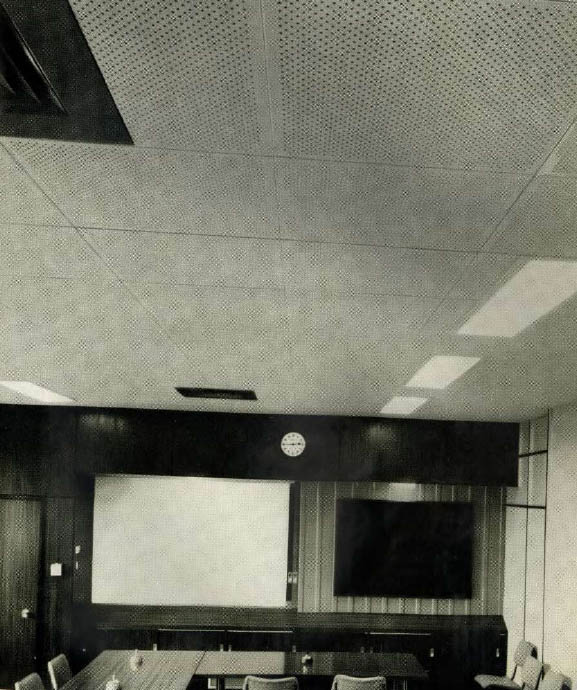

Also used for counter-front facades in public reception office areas, halls, spandrels and interior walls and partitions.

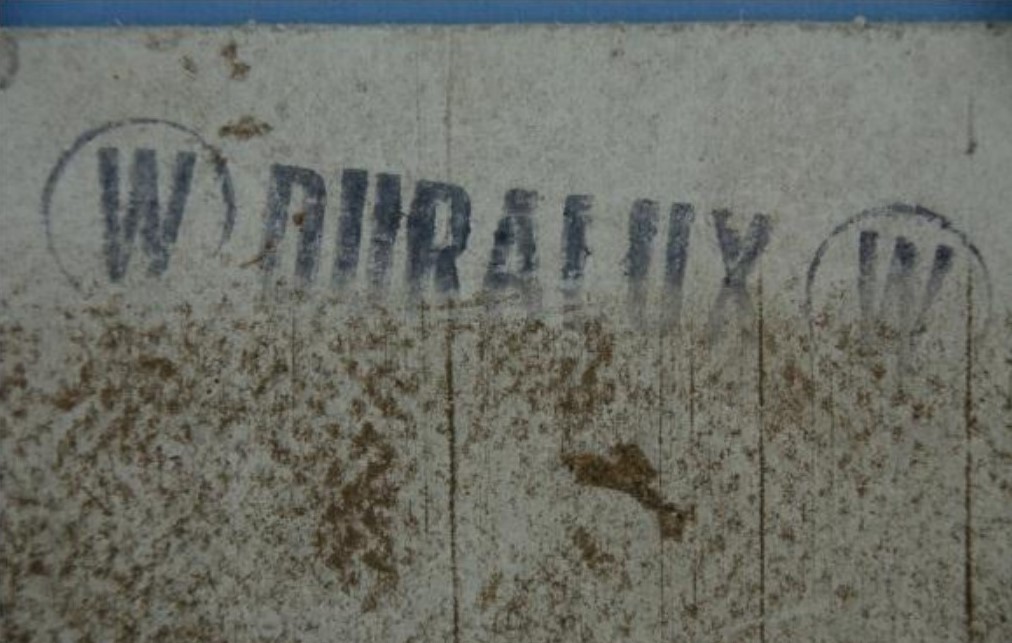

Wunderlich Duraveneer was advertised as being faced with actual Queensland walnut and maple timbers.

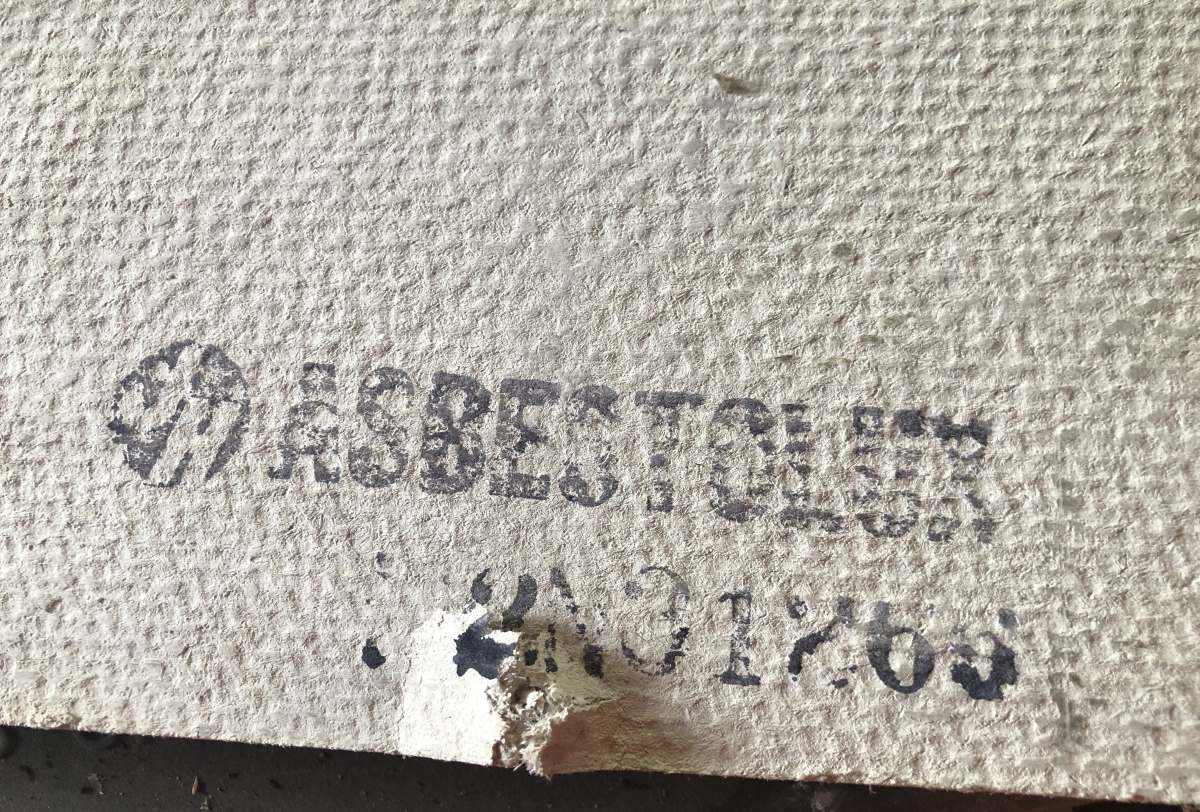

Asbestos Products Limited produced Armac, described as easily mistaken for highly polished expensive timber. Likely an imitation timber and advertised as available in a range of wood grains. Armac may have been manufactured in an identical manner to a laminated AC sheeting for wet areas (Artyle), which was a Tilux-type of product.

Brands/products

- Armac

- Duraveneer

Years of production/use

1930s – 1940s

Residential uses

- Interior facades, fireplaces – older residences built or renovated up until late 1940s

Industrial uses

- Older commercial offices, council buildings, banks, public facing areas – built or renovated up until late 1940s

Be aware

Actual woodgrain veneers may require core sampling or partial deconstruction to identify AC sheeting.