Home / Insulation / Sprayed coatings of asbestos

Sprayed coatings of asbestos

Description

A mix of up to 85% pure asbestos fibre, cement and an inorganic binder. Introduced into Australian construction in the early 1930s.

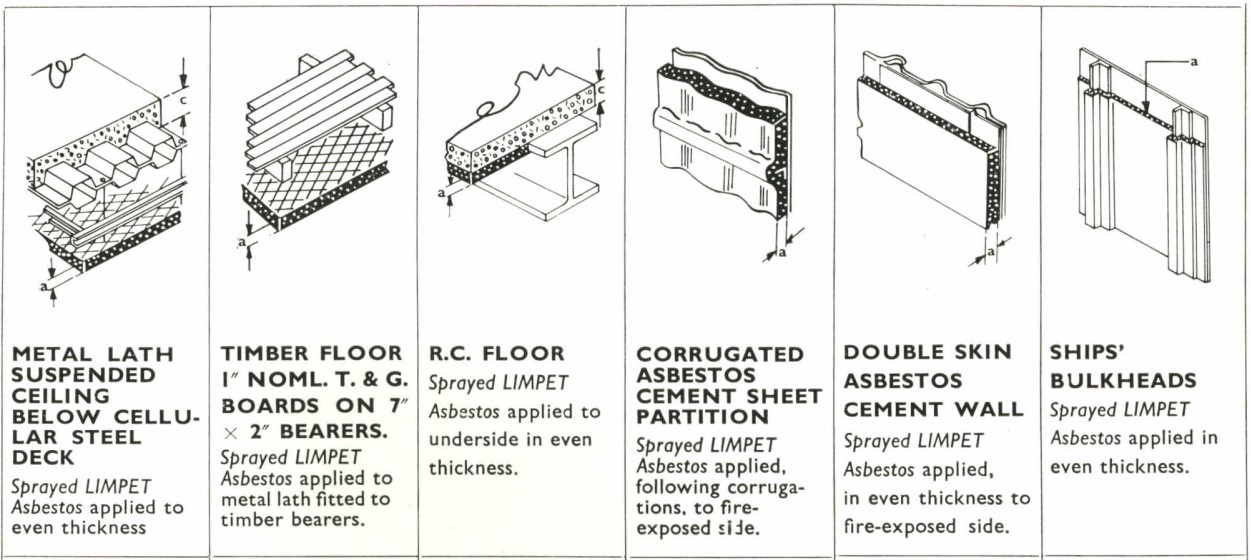

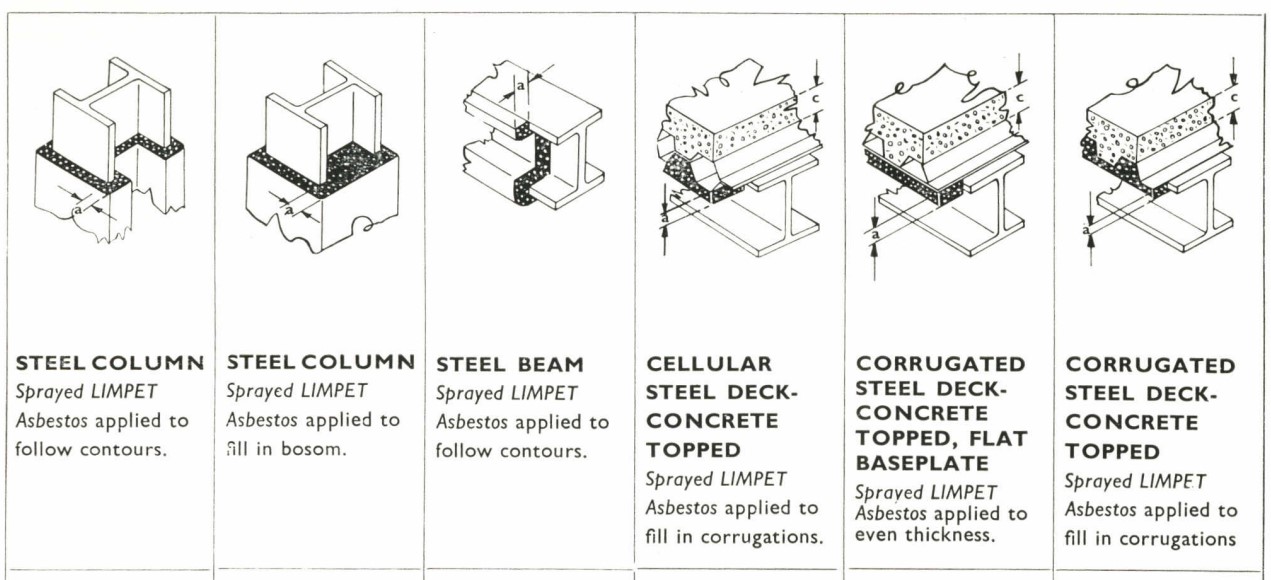

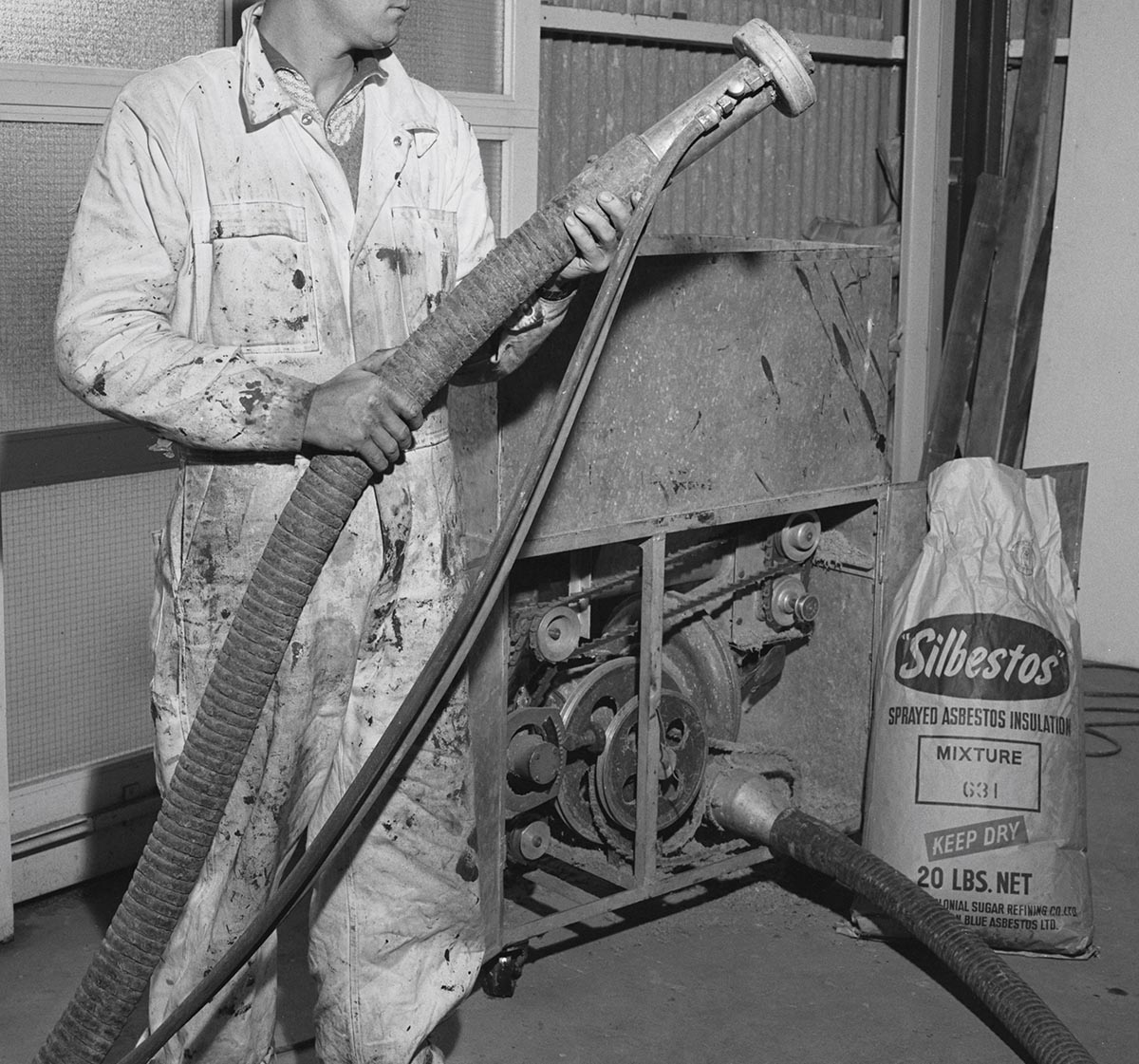

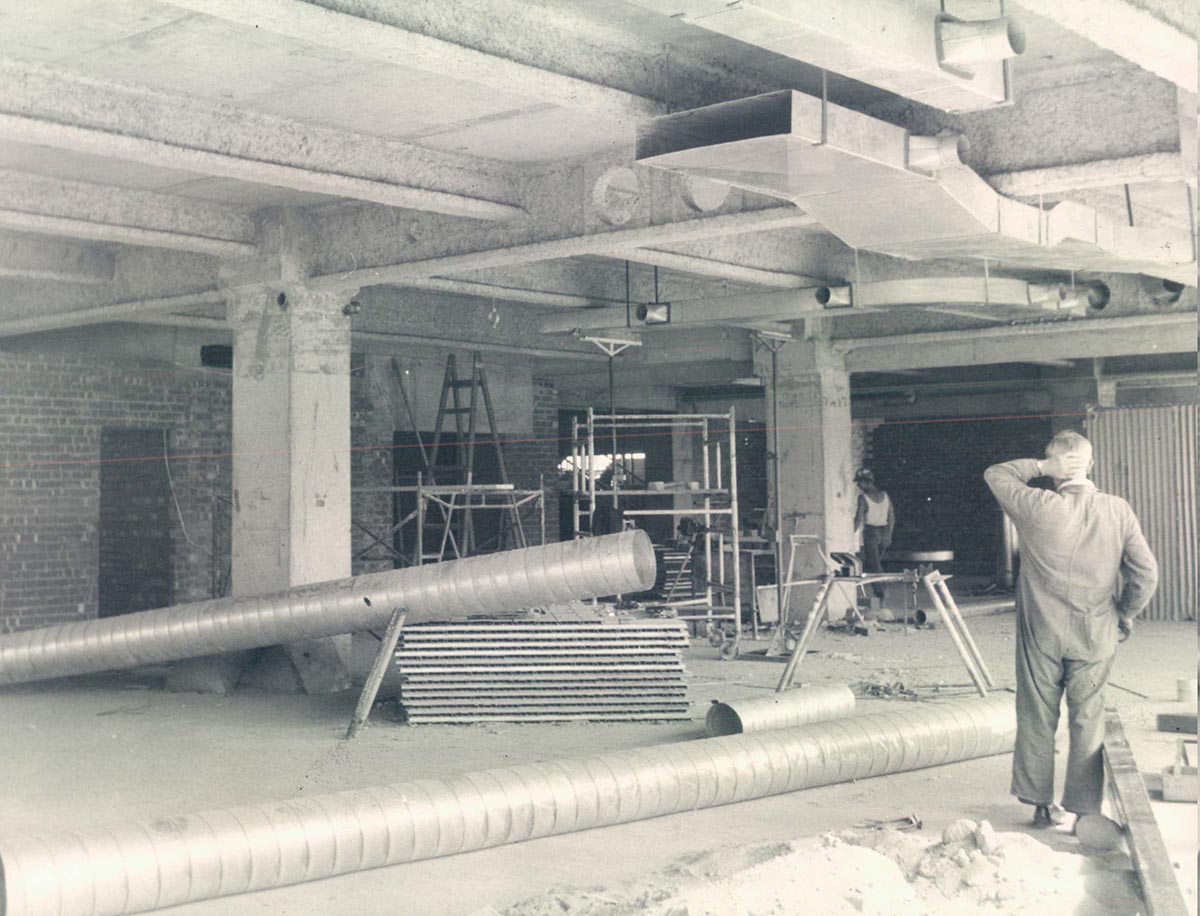

Applied with industrial-sized sprayers with jets of atomised water to the underside of roofs and in multi-storey ceiling tween-spaces on underside of floors. Used to achieve building fire-rating on steel and reinforced concrete beams/columns, thermal insulation, acoustic correction and as anti-condensation for corrosion resistance.

Left to dry with rough accumulated surface or tamped (trowelled) smooth. Usually white or grey in colour, may be painted. Advertised as able to be used on any surface, such as metal, masonry or cement. Repeatedly featured in architectural articles in the 1930s for its use as an acoustic correction or sound insulation material for interiors (theatres etc). Its use was not always an after-thought in construction but incorporated into building design. Sometimes referenced as flocculent. In acoustic applications, such as theatres, it was applied with less hardeners, which resulted in a slightly cushioned surface to touch. Hardeners were incorporated in foot traffic areas such as around staircases and foyers.

Often colloquially referenced as Limpet, which was a branded product imported from UK which gained a fair market share in Australia through a number of licensed installers.

Post Master General (PMG) internal instructions issued 1968 approved the use of Limpet B2 Hardset and required small warning signs installed to prevent fixings being later applied to steel beams, where installed in telephone and mail exchanges. Asbestos surveyors of these older or former structures should take note.

Another method of application around beams was a ribbed expanded metal box supported and surrounding the beam. The spray coating was applied to the surrounding profile and was a more economical profile for hard-set applications. This method was approved for use in PMG facilities.

Brands/products

- Bradford Insulation Industries

- Silbestos (CSR)

- Asbestospray

- Limpet (JW Roberts – UK)

- Limpet LW25

- Limpet LW26

Toughening coats containing PVA:

- Limpet TS5

- Asbestospray Type S

Hard coatings containing Portland cement:

- Limpet B2 Hardset

Multiple coatings were sometimes applied over the base coating in industrial sites to meet specific requirements:

- For additional protection to prevent damage or dusting of the surfaces which might be subject to mildly abrasive conditions, toughening coats contained the synthetic polymers PVA or Sodium Silicate SB-112. Suitable for exposed beams.

- For high impact and abrasion resistance and/or weather resistance, a hard-set coating of AC was applied and usually trowelled to a smooth finish with minimum thickness of 3/16” (4.7mm).

JW Roberts technical data sheets for Limpet sprayed asbestos coatings (circa 1960s) state: …structures protected by Sprayed LIMPET Asbestos achieve the highest possible fire resistance ratings. It should be noted that these ratings are obtained with (Limpet) coatings of minimum applied thicknesses, at densities as low as 9lb/cubic ft (144kg/cubic metre).

Years of production/use

Residential uses

- Lift machinery/electrical/air conditioning rooms in multi-storey apartments

Industrial uses

- Tween floor structures, upper rigid structural areas (shielding, columns, beams, purlins, braces and girts), under roofs

- Warehouses, factories, foundries, government and military structures, power stations, electrical sub-stations, plant/generator rooms, telephone exchanges, ducting etc

- Offices and public buildings (banks, theatres, hospitals, covered swimming pools), above false or suspended ceiling systems, buildings adjacent to noisy roadways etc

- Thermal and sound insulation applied to inside and underside of older (1940s-60s) railway rolling stock.

Be aware

Breaks up very easily. Minor disturbance of sprayed ACM coatings can release large quantities of asbestos fibres.

Overspray and splash back often occurred at the site from the equipment, requiring clean-up. In isolated spaces cleanup may have not been undertaken and so likely to be ACM debris around the sprayed area.

These products can contain chrysotile, amosite or crocidolite asbestos types, or a mixture of.

Silbestos, used by Bradford Insulation Industries, contained crocidolite asbestos.

Applying Silbestos sprayed asbestos insulation, July 1960 / photographs by Max Dupain & Associates – State Library NSW