Home / Insulation / Pipe insulation (lagging)

Pipe insulation (lagging)

Description

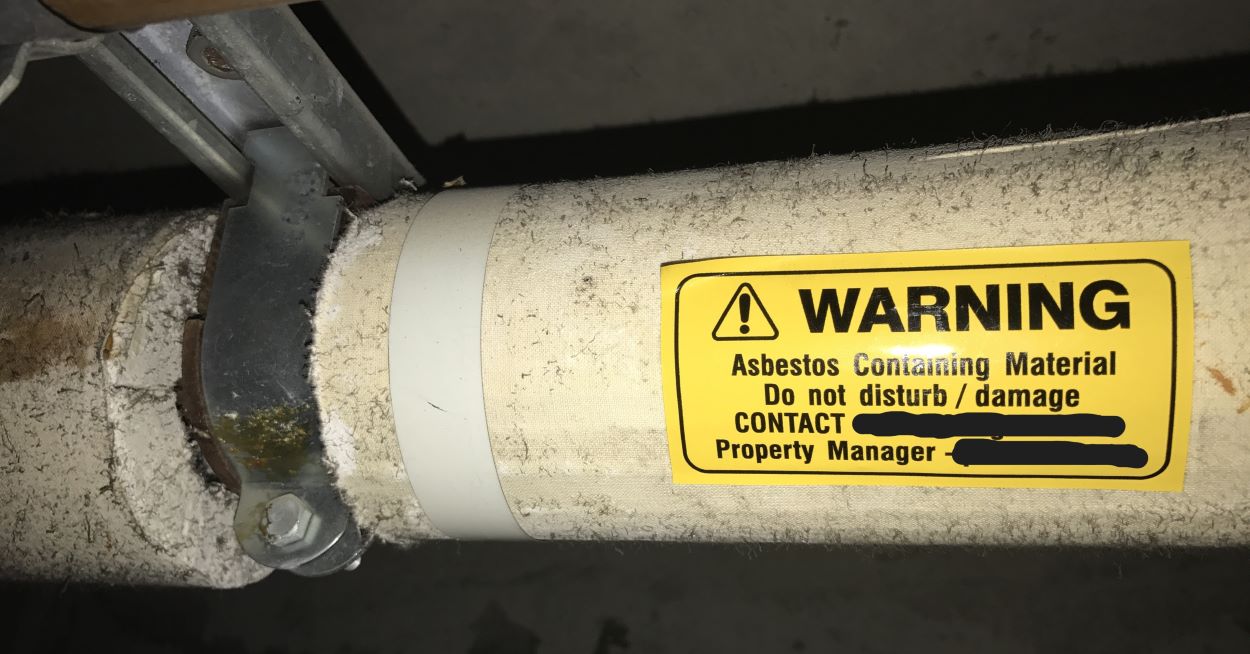

Lagging is a term which has become accepted as describing the insulation material applied to structures such as pressure pipes.

Asbestos lagging is commonly interpreted as the insulation material containing the asbestos fibre which can vary in its composition of asbestos content, type and bonding materials, each designed for specific temperature requirements, particularly in industrial applications.

Locally produced by Hardie’s, CSR and other smaller manufacturers. A large amount of imported material was used for pipe insulation. Sourced from UK and US based manufacturers and supplied through licensed agents in Australia.

Jacketing material used can also vary: Calico, cotton.

Brands/products

Refer to information pages: 85% Magnesia, Caposite, K-Lite and High Temperature.

The insulation material was marketed under various product names and varying ingredients:

- Compounds of asbestos with either magnesium carbonate, sodium silicate or diatomaceous earth (mineral-like material of fossilised aquatic organisms).

- Asbestos paper worked into radiused sections of flat and corrugated laminates.

- Asbestos felt, which was used on gas pipeline infrastructure.

Years of production/use

1800s – 1990s

Residential uses

Apartment complexes with common-supply pressure pipes

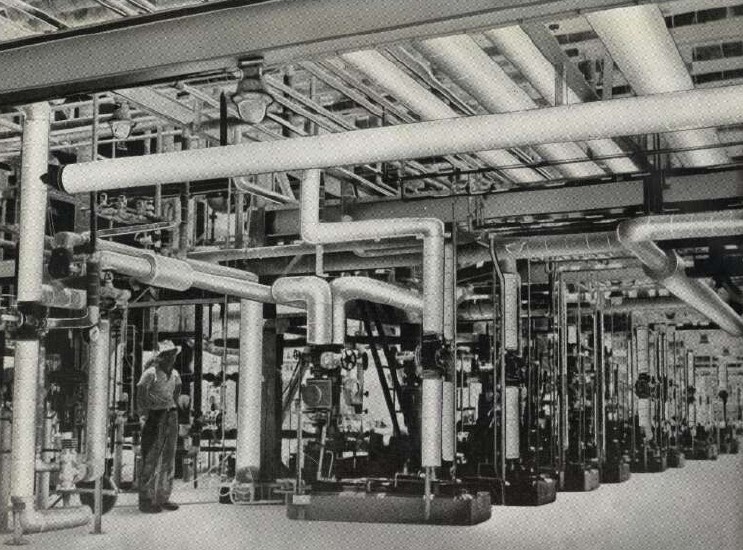

Industrial uses

Pressure pipes, heating/cooling systems, plant infrastructure, commercial and public infrastructure (eg hospitals)

Be aware

Materials will degrade over time from temp variances and environmental effects.

Debris in vicinity, whether from damage or maintenance, may contain asbestos fibres.

Original ACM may still be in-situ which has been encapsulated in jacketed mineral wool or fibreglass.