Home / Adhesives, sealants & coatings / Fixings for AC roofs, walls and gutters – use of bituminous washers and asbestos compounds

Fixings for AC roofs, walls and gutters – use of bituminous washers and asbestos compounds

Description

The use of bituminous washers with roofing screws/bolts and gutter bolts, in conjunction with bitumen sealing compounds, was accepted practice recommended by the Australian suppliers of AC product including sheeting, roof gutter systems and flashing. Prior to the asbestos ban, bituminous washers and bitumen compounds often contained asbestos as a raw material binder.

Brands/products

- Hardies

- Wunderlich

- CSR

- Tasbestos

- Asbestolite

Residential uses

All roofing and walling installations applicable to instructions.

Industrial uses

All roofing and walling installations applicable to instructions.

Roof fixings for corrugated asbestos cement sheets

Hardie’s (1963) instructions for installing Fibrolite Super Six AC sheeting included:

Fixing to steel purlins:

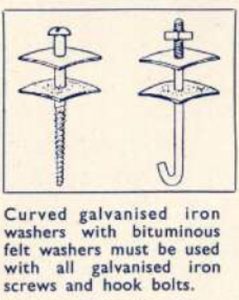

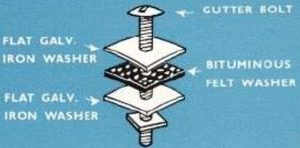

For fixing to steel purlins, ¼”dia. galvanised hexagon-headed Roofing Set Bolts are used, together with curved galvanised iron washers and bituminous felt washers.

Hardie’s (1961) instructions for installing Fibrolite corrugated AC sheeting included:

Fastenings for roofing

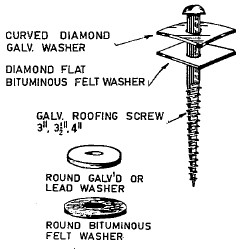

Galvanised Cone Head Screws, with curved galvanised iron washers and bituminous felt washers, for fixing to timber purlins or battens. Allow 1 pint plastic bitumen compound per 200 screws, for sealing.

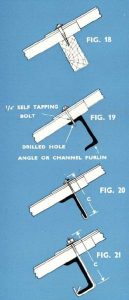

Galvanised Self-Tapping Bolts, together with curved galvanised iron washers and bituminous felt washers, for fixing by screwing into steel angle or channel purlins. Allow 1 pint plastic bitumen compound per 200 bolts for sealing.

Plastic bitumen for screw and bolt holes:

Before screwing or bolting the sheets to the purlins or battens, the fixings (screws or bolts) must be dipped in plastic bitumen to seal the fixing hole in the sheet. When bolts are inserted from inside the building, the plastic bitumen must be liberally applied to the bolts beneath the iron and bituminous washers. Allow 1 pint plastic bitumen (Bitmas) per 200 screws or bolts.

Wunderlich (1965) installation instructions for Durabestos corrugated sheet roofing included:

Pitch and end lap

The following standards have been adopted in our Industry:

Roof Pitch at Eaves: Below 7I° to min. 5°. Rafter Length: Not exceeding 30 ft. Specification: End laps and accessories bedded with plastic asbestos bitumen compound. Roof Pitch at Eaves: Below 7I° to min. 5°. Rafter Length: Over 30 ft. but not exceeding 70 ft. Specification: End laps and accessories for top 30 ft. rafter from centre line of ridge bedded with plastic asbestos bitumen compound. Balance of roof below this 30 ft.—end and side laps and accessories bedded. Roof Pitch at Eaves: Below 10° to min. 7I°. Rafter Length: Not exceeding 70 ft. Specification: End laps and accessories bedded with plastic asbestos bitumen compound.

End laps and accessories for top 70 ft. rafter from centre line of ridge bedded with plastic asbestos bitumen compound.

End laps

Exception: Where the rafter length can be covered by a single sheet (max. 10 ft.) a roof may be pitched down to a minimum of 2l° at eaves, provided the side laps and accessories are bedded with plastic asbestos bitumen compound.

Sealing of laps

Depending on the roof pitch and length of rafter, end laps and/or side laps require sealing as specified in the tabulation above. This applies also in “Snow” country and in cases where it is essential to guard against the infiltration of dust, soot, etc.

NB: End laps/side laps refers to overlapping sheet ends/sides placed to ensure no water/dust ingress.

Be aware

Bituminous washers would break and slip with pressure if the screw/bolt was installed too tight.

Asbestos containing compounds were sometimes used as an alternative to bituminous washers or used to later replace damaged bituminous washers during maintenance.

Wall fixings for corrugated asbestos cement sheets

Wunderlich (1965) installation instructions for Durabestos guttering included:

Fastenings for walling:

Galvanised Cone Head Screws, together with curved galvanised iron washers and bituminous felt washers, for fixing to timber girts.

¼” Galvanised Hook Bolts, together with curved galvanised iron washers and bituminous felt washers, for fixing to angle iron girts on walls.

¼” Galvanised Hook Bolts, together with curved galvanised iron washers and bituminous felt washers, for fixing to reverse angle iron girts on walls.

CSR (1950s) instructions for installing Fibrock corrugated AC sheeting included:

On exterior walls, “Fibrock” is nailed direct to the timber studding, or over the Cane-ite sheathing, if used…Vertical joints are sealed with a strip of bituminous felt or filled with mastic putty, before battening. Galvanised iron or heavy bituminous felt flashing must be used at horizontal joints before nailing the battens. Other methods of jointing include the use of metal connector strips or bitumen-coated heavy aluminium foil.

“Fibrock” is normally fixed with 1½” corrugations side lap and is secured to purlins or battens with screws fitted with felt and galvanised washers. The screws are dipped in a bituminous compound before screwing.

Moulded asbestos cement gutter fixings

Wunderlich (1965) installation instructions for Durabestos guttering included:

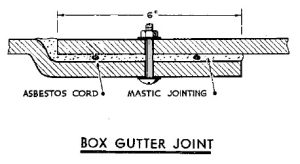

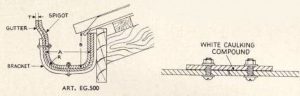

Durabestos box gutters

A round bituminous felt washer is necessary under the bolt head with a round bituminous felt and lead washer under the nut. Insert a length of asbestos cord between the collar and plain end, as shown by detail at right [above diagram], then fill the gutter joint with plastic asbestos bitumen compound, using sufficient to completely fill the cavity when drawn together by the gutter bolts. Trowel with plastic asbestos bitumen compound on the inside of the gutter joint, covering approximately 2″ on each side of the joint, care being exercised to completely cover the nut and washers.

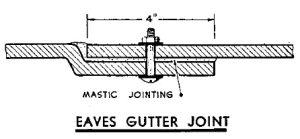

Durabestos eaves gutters

Fill the gutter joint with plastic asbestos bitumen compound, using sufficient to adequately seal the joint when drawn together by gutter bolts which are fixed by drilling through the collar joint.

Hardie's (1961)

Hardie’s (1961) provided similar instructions for the use of a caulking compound, recommending Selleys Ezy-Calk, which does not appear to have contained asbestos. No instruction for the use of asbestos cord was provided as the caulking compound, squeezed from a tube, provided this feature.

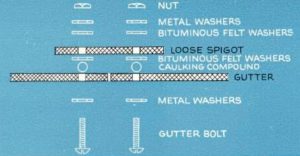

Fibrolite eaves gutters

Remove loose spigot and clean dust from joint, cut end of tube of Ezy-Calk, so that it produces a cord of sealing compound approx. 3/80-1/2″ diameter, which is placed on the inside of the gutter on the line of the fixing holes. A round bituminous felt washer is then placed on the sealing compound directly above the fixing holes. The loose joining spigot is then inserted and carefully pressed into position.

NOTE: When making a joint, a caulking compound (supplied on request) should be applied in three narrow bands to the inside of the gutter; and the spigot, outlet or stop-end bolted firmly in position to form a watertight joint.

Be aware

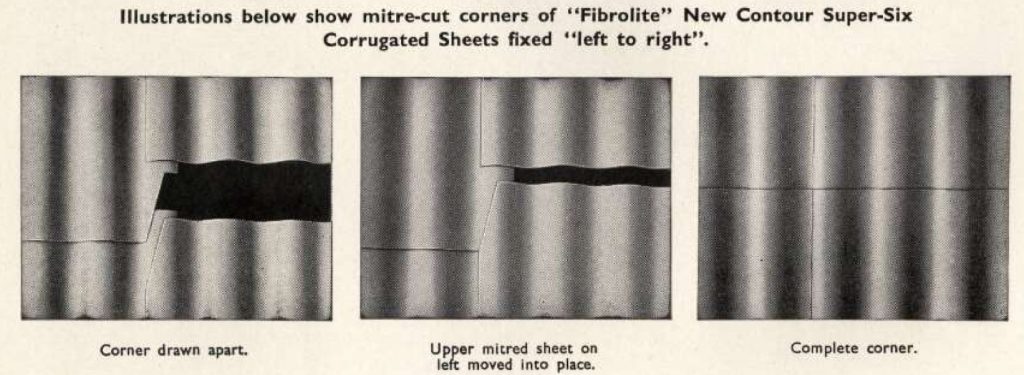

Sealants used at mitre cuts of sheet overlaps may be from installation or from later repairs.

Written instruction vs actual practice may have resulted in asbestos caulking compounds being commonly used for installation and repairs. Unless known otherwise, assume that sealants and compounds in-situ will contain asbestos.

Bituminous washers containing asbestos and set into a compound, will likely break if attempted removal is made.