Home / Building structures & components / Walls / Low density board (LDB)

Low density board (LDB)

Description

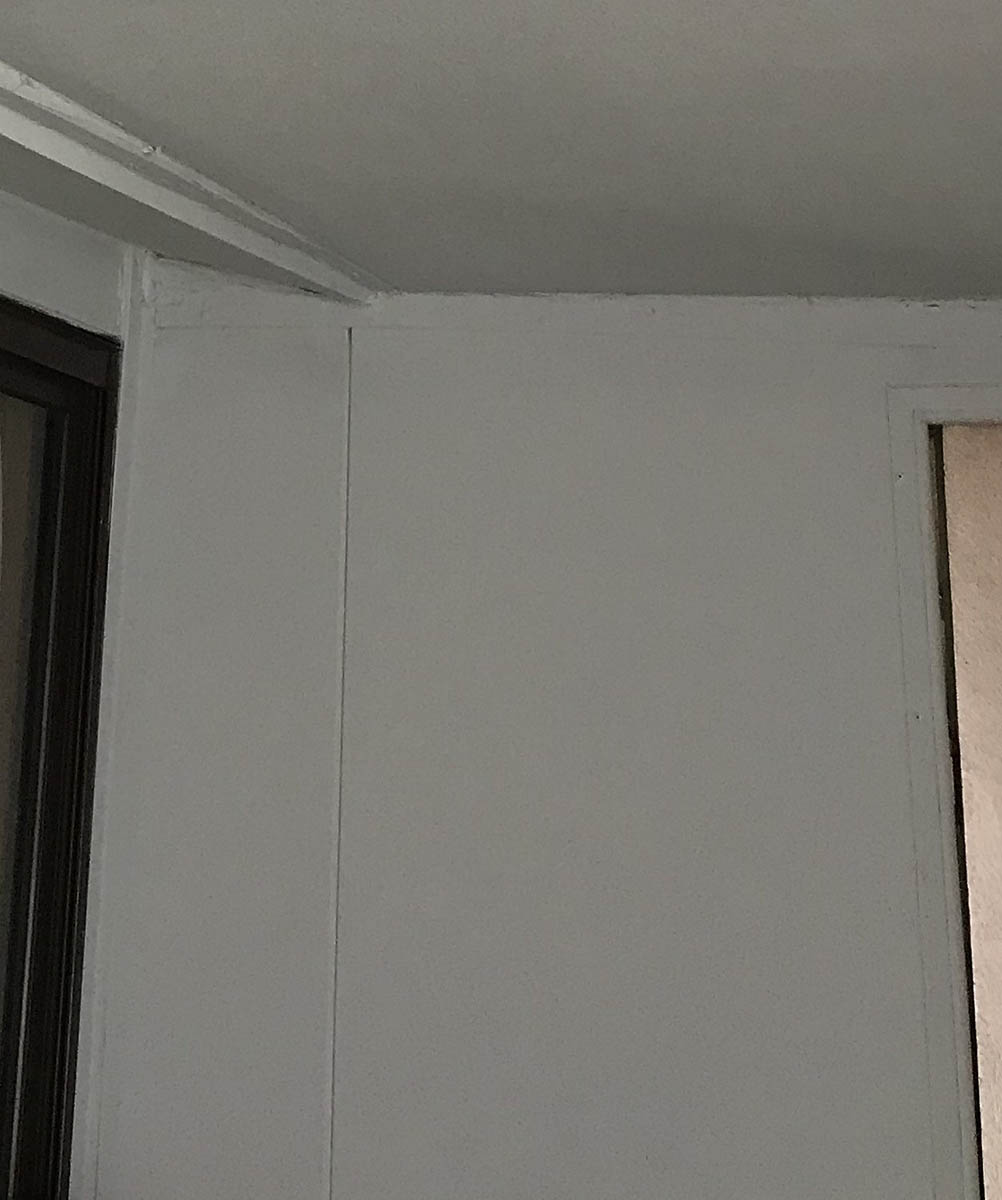

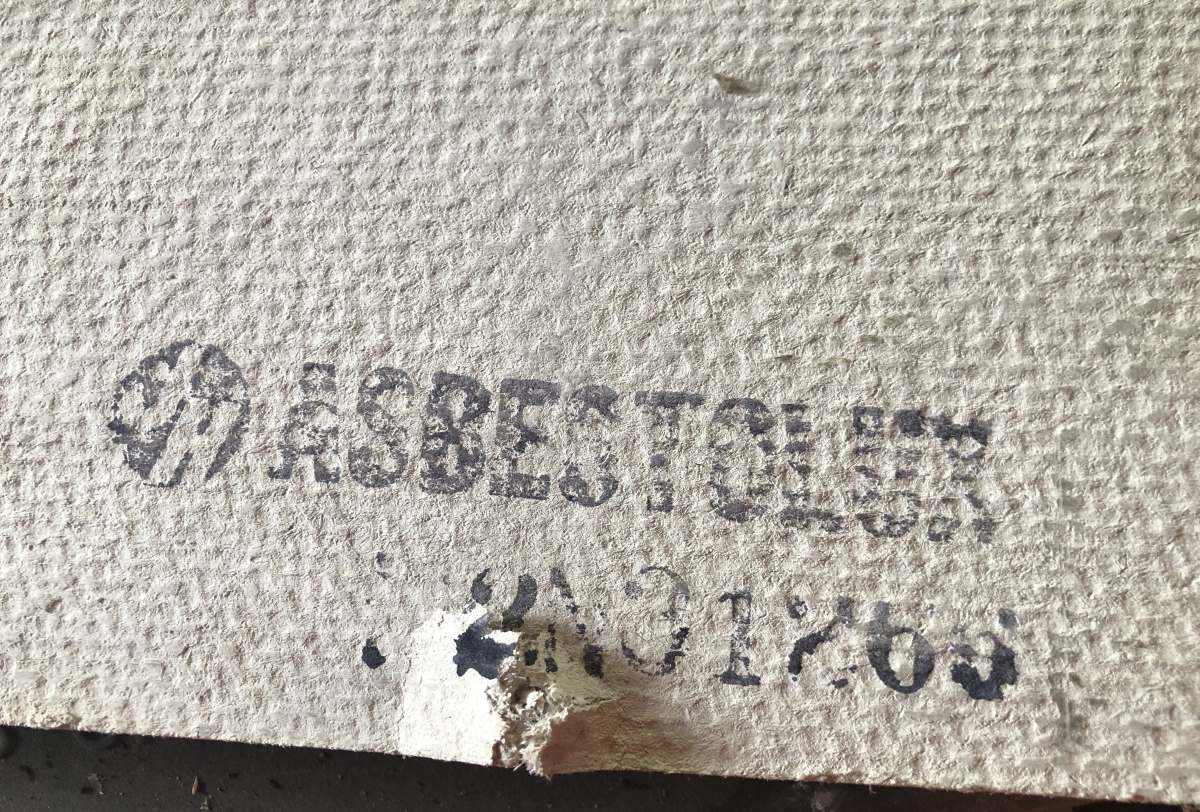

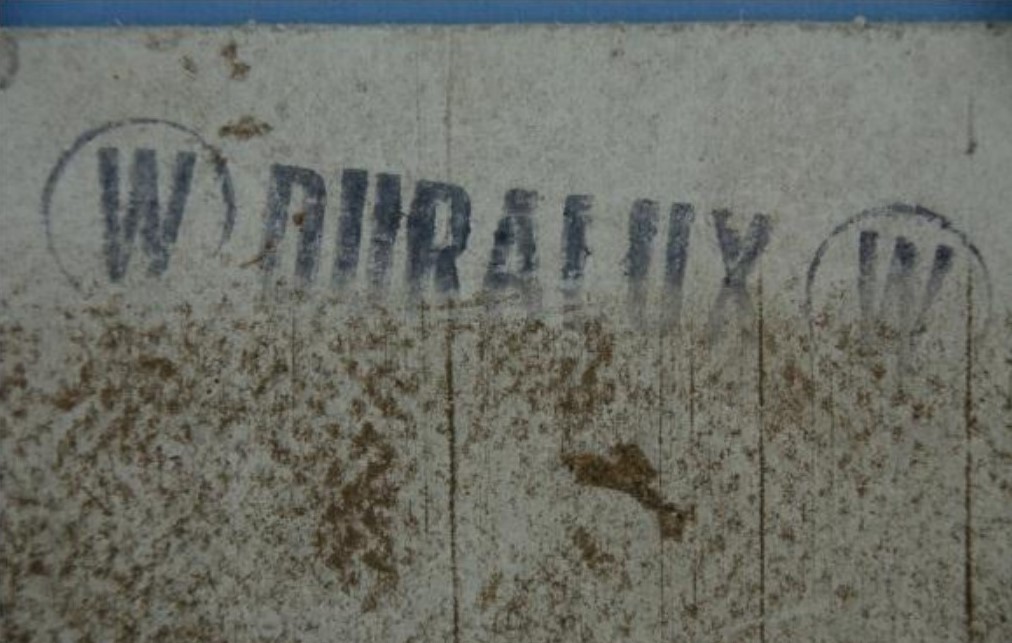

Also known as asbestos insulating board (AIB). Sheeting of similar visual surface appearance to asbestos cement sheeting. Used for walls and ceilings between 1950s-70s. Solid or perforated. Produced in 4.5mm, 6.5mm, 9mm and 12mm thicknesses. Unpainted, it tends to have a slightly blue-grey appearance as opposed to a more whitish grey appearance of regular AC sheeting.

Marketed as non-combustible light weight interior lining for insulation under hot water tanks, heaters, ironing boards, behind stoves and cupboard linings.

Often made from amosite asbestos mixed with chrysotile asbestos and calcium silicate plaster as the binder. Lighter material, more advantageous to logistics and installation. Amosite was thought to have better fire resistance qualities.

Rear side of LDB is usually dimpled. Edging often bevelled so sheet joints will appear to have V-shaped valley when butted together. Squared edges (stone cut) also produced.

It is a structurally softer material and easily dented from a slight impression with a tool.

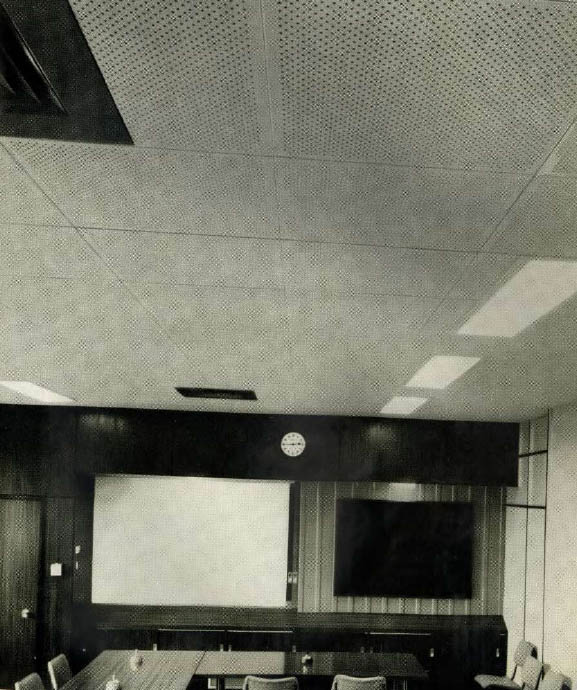

Used in ceiling tiles, solid and perforated for acoustic qualities. Advantageous for noisy high human traffic areas such as schools. See ceiling tiles information page.

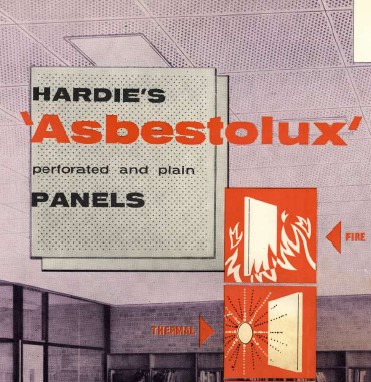

Hardie’s Asbestolux was advertised as ‘…protection from fire, sound, heat, cold and condensation.’

CSR/Wunderlich Bevelux was advertised as: ‘…will not shatter when exposed to intense heat.’

Often favoured in climates with high humidity (northern Australia), as its structure was more moisture resistant.

Brands/products

- Asbestolux

- Duralux (Wunderlich Qld)

Duralux is also a current brand name for a fibre board product manufactured in Australia with no asbestos

- Bevelux

- F.R. Board

Since May 2021, LDB is classified as friable in all circumstances under Queensland law.

Years of production/use

1950s – 1970s

Residential uses

- Interior walling and ceiling of houses and apartments. Also perforated sheets used in workshops as tool peg boards.

- Soffit panels under eaves.

- Generally ceilings in multi-storey buildings.

- Floor insulation beneath hot tanks, heaters. Under floor insulation above lower floor garages. Lining of cupboards and behind stoves.

Industrial uses

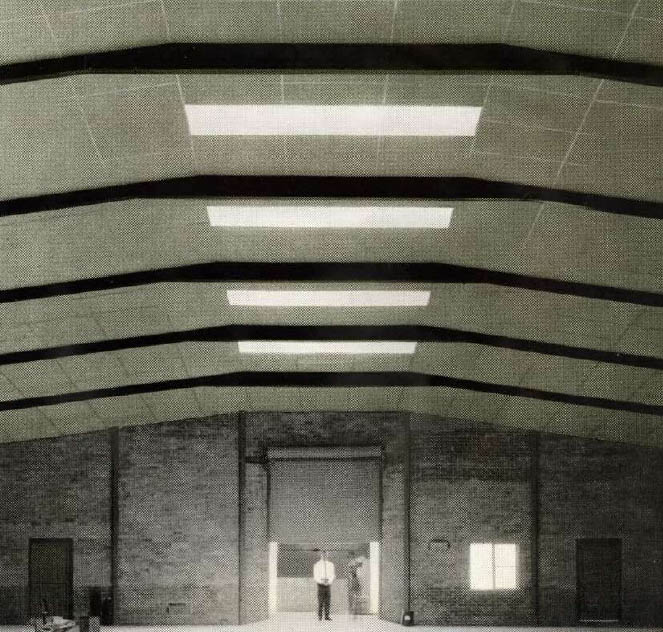

- Factories, workshops, shops (particularly as ceilings in flat-roofed rows of), community and government buildings (including military), schools, food processing plants, laundries, textile plants, kitchens, laboratories, bakeries, hospitals, interior of aircraft hangars, offices etc.

- Underside of mezzanine offices or outer facing walls between factory and office spaces

- Used as ‘fillets’ for fire rated structures – see: AC tween panels (Fillets) for fire rated ceilings information page.

- Draught fire curtains, industrial ovens/driers, high temp trunking and ducting, heat shields, linings for foundry pallets, moulding boxes and electrical circuit boxes.

Be aware

LDB is easily damaged. Tears like cardboard. Estimated asbestos content is up to 70%.

Safe Work Australia Guide: How to identify and handle low density asbestos fibre board

Once painted, LDB sheeting with bevelled edges may have a Masonite-type appearance.

Often used as an insulation material in preference to Millboard, particularly in humid zones.