Home / Building structures & components / Other building components / Compressed flat asbestos cement sheeting

Compressed flat asbestos cement sheeting

Description

Compressed, high density AC sheet with double face, thicker than common AC flat sheeting. Sold in square or rectangular panels. Smooth face both sides or with single side non-skid patterned face.

1980 specs show production was in thicknesses of 6mm, 9mm, 12mm, 15mm, 18mm and 24mm.

Internal and external use. Developed for weather-proof, moisture-proof applications.

A dense, high strength, building product for bathroom/toilet partitions in commercial premises and public buildings, spandrel panels and porch flooring. Advertised for curtain walls, balustrades on bridges and balconies, stairtreads, bathroom floors, underlay for tiles, suspended decks, sub-floors, sun louvres, windowsills, tunnel linings, laboratory bench tops and permanent formwork applications such as bridge decking. Advertised as able to be applied directly to joists.

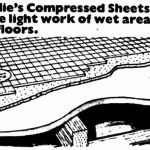

Hardie’s technical publications for the construction of decking with compressed sheeting recommended the use of AC spacing strips (offcuts) and AC internal angles as base moulding (1980).

Brands/products

- Fibrolite

- Fully compressed thick sheets

Years of production/use

Late 1960s-1980s

Following the cease of asbestos use, Hardie’s manufactured an identical cellulose fibre product under the name Compressed Sheet II. This may be branded on the underside edging. If unsure, sampling for testing by a NATA accredited laboratory is the only method of confirming the non-asbestos product.

Residential uses

Decks, landings, flooring, balustrades on multi-storey apartments

Industrial uses

Balustrades on bridges, toilet and changeroom partitions

Be aware

Weathering combined with direct contact such as foot traffic, will have increased damage effect.

External decking with a compressed sheet upper surface may have a second layer of AC sheeting installed underneath, separated by sarking.