Home / Building structures & components / Floors / Vinyl flooring and tiles with asbestos

Vinyl flooring and tiles with asbestos

Description

Asbestos backed vinyl flooring and tiles, or asphalt tiles that have visual appearance of vinyl or linoleum.

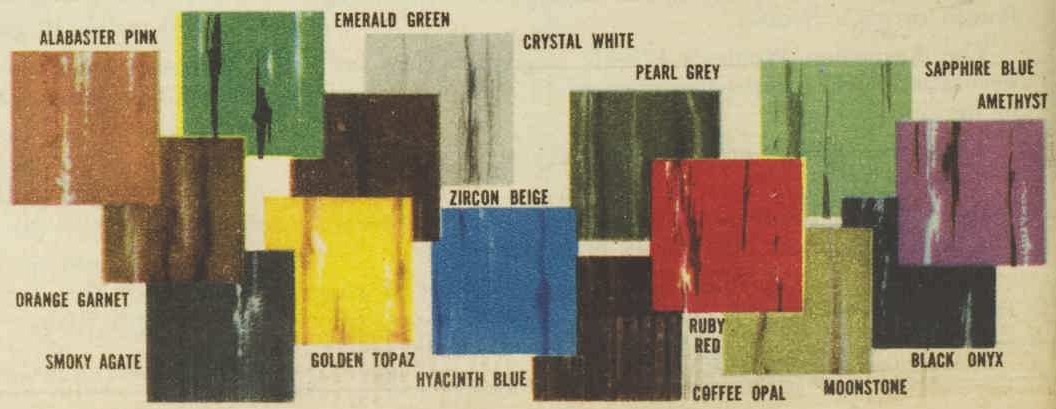

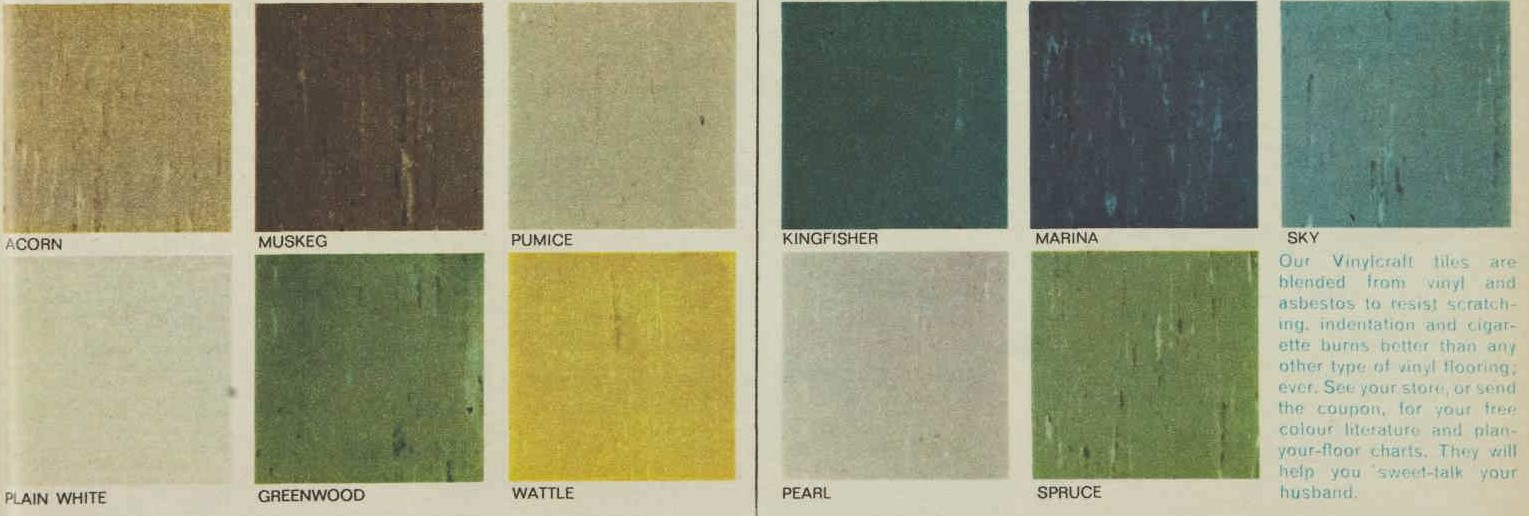

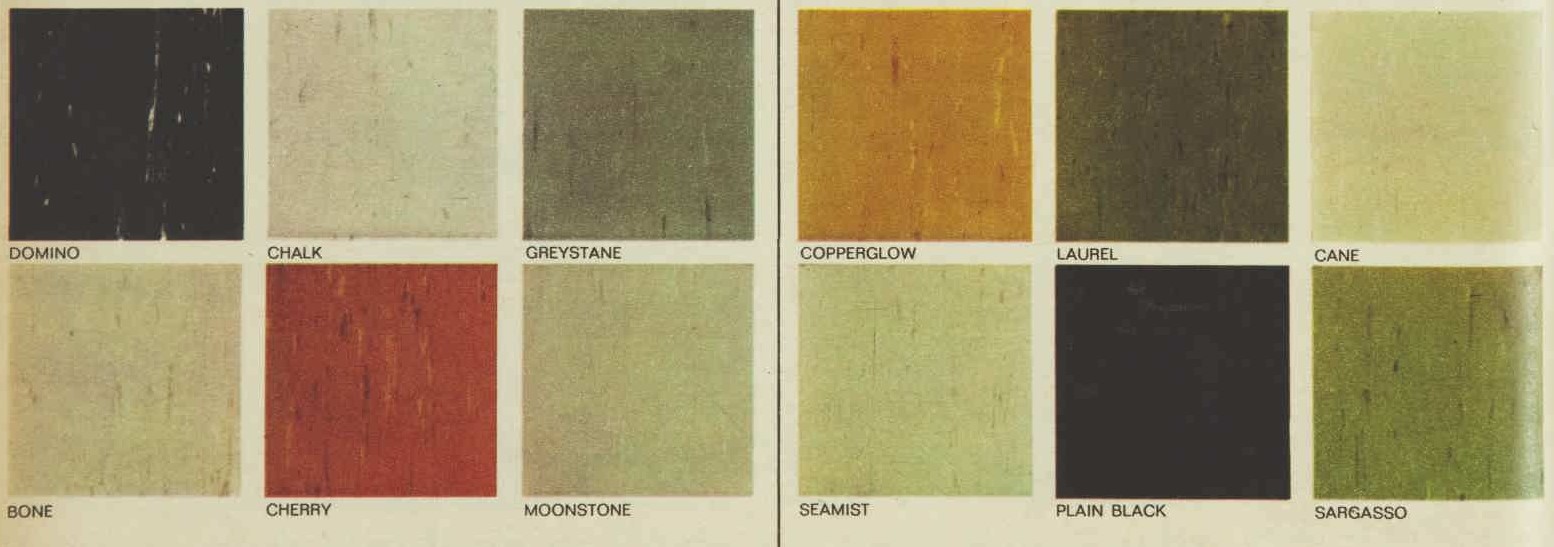

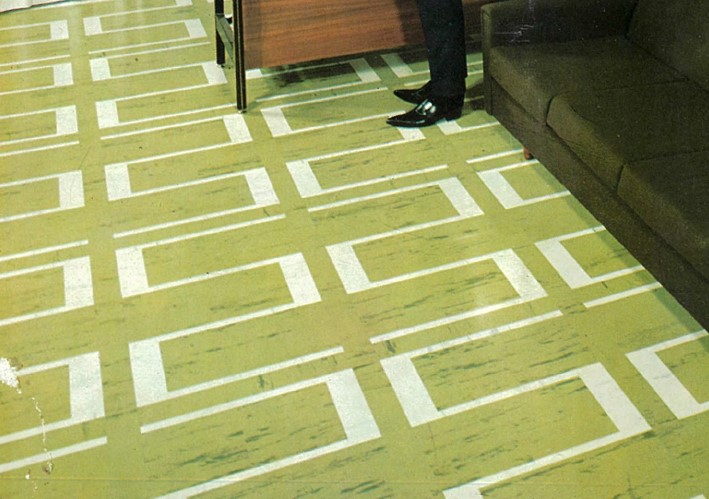

Large range of colours and patterns marketed to DIY homeowners over decades.

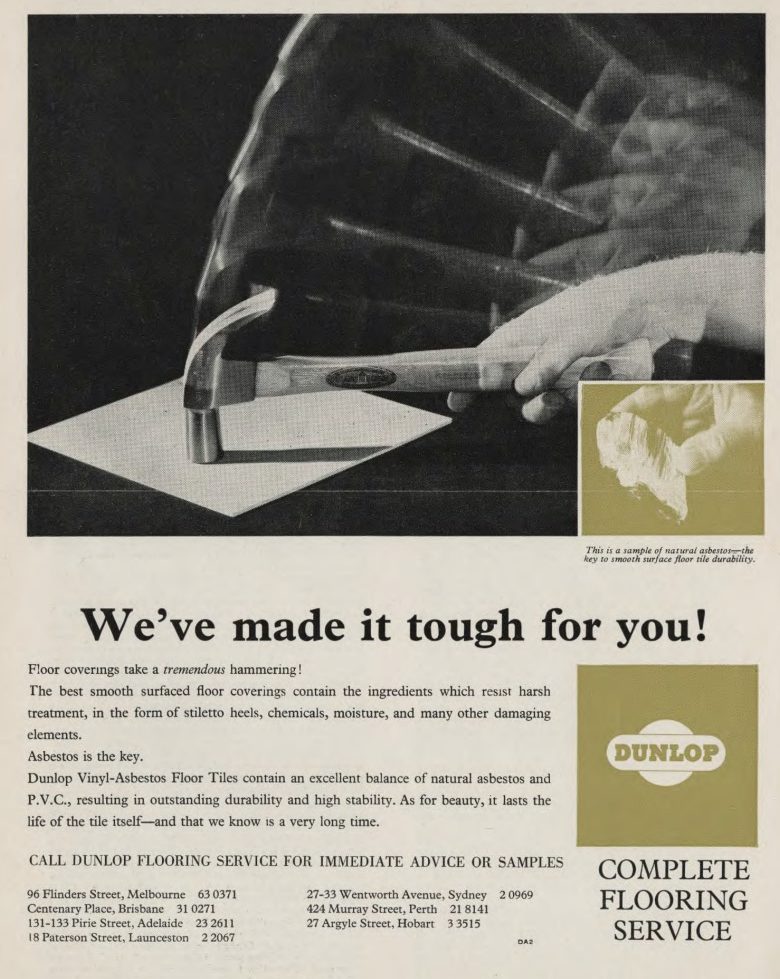

Produced in Australia 1950s-1970s.

CSR Vinylflex asbestos flooring was still being marketed in 1979. In 1982 CSR sold their Vinylflex production arm to US-based manufacturer Armstrong-Nylex.

While manufactured in Australia, a large amount of production occurred in USA. Accurate volumes of imported flooring and tiles for sale in Australia during this period cannot be estimated.

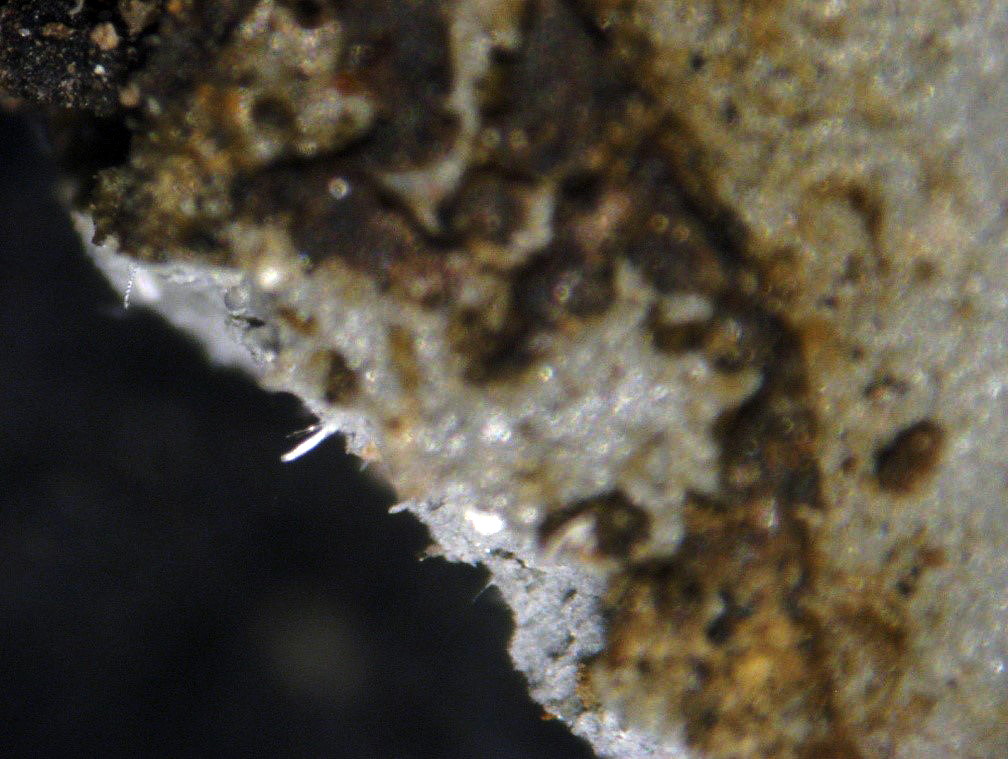

Asbestos content could range 20-45%.

Years of production/use

Production: Prior to 1980s

Use: prior to 1990

Brands/products

- Vinylflex (CSR)

Vinylflex is also a current brand name for PVC based tiles and other goods with no asbestos.

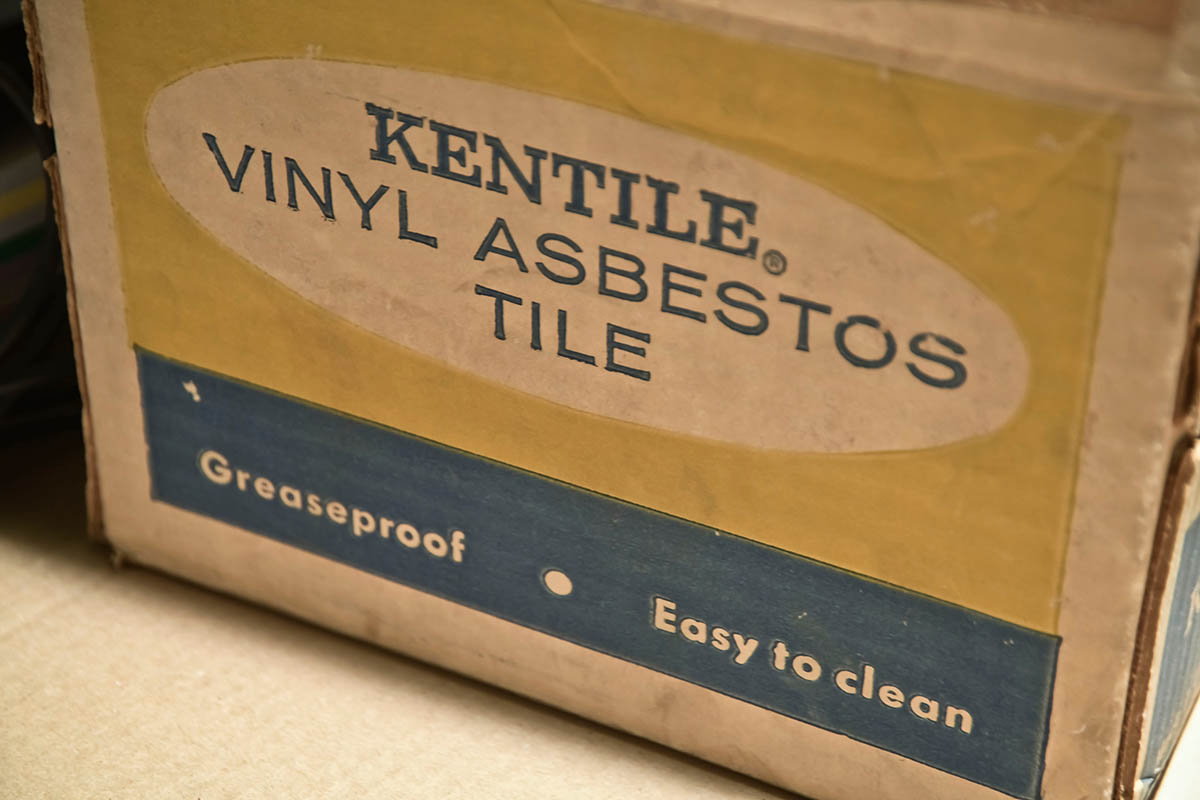

- Kentile (USA)

- Asphalt tiles (CSR)

- Johns Manville (USA)

- Dermide

- Vinylcraft (Nairntile)

- Dunlop Vinyl

- Olympic Tyre and Rubber

- Supervinyl (Nylex)

- Royal Flexyl

- Armstrong Cork (Australia)

- subsidiary of Armstrong Cork Co (USA)

Residential uses

- Kitchens, laundries, bathrooms, and offcuts used to line cupboard shelving

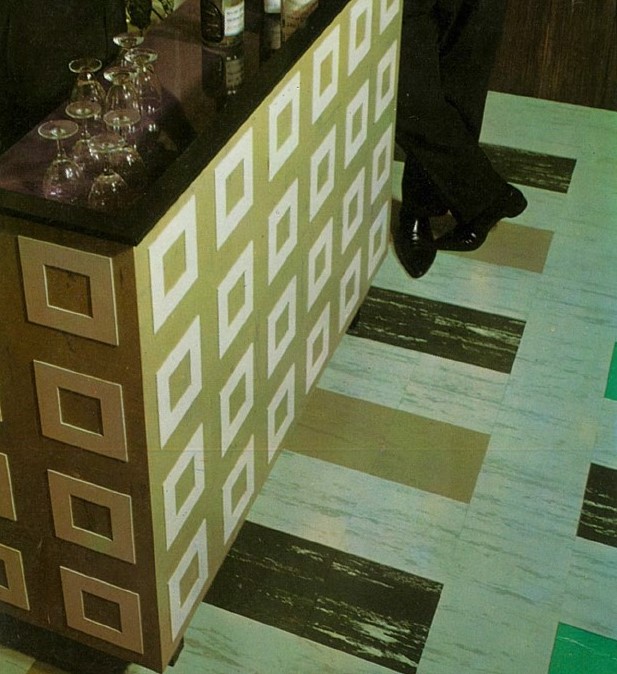

- Splashbacks and feature walls in kitchen or laundry areas

Industrial uses

- Offices and commercial buildings, commercial kitchens, shops, cafés, restaurants, department stores, bowling alleys – community buildings/halls with high foot traffic

- Government buildings – Defence, telecommunications, hospitals and other offices

Be aware

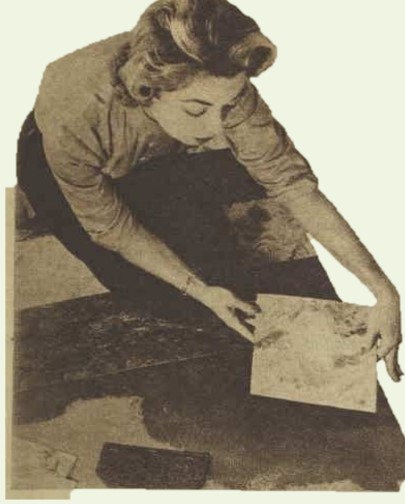

Paint-on adhesives for attachment to floorboards/slabs may also contain asbestos. Particularly if black in colour.

Non-asbestos flooring may have been overlaid on top to reduce cost/workload of removal.

Underlays of AC flat sheeting or asbestos felt.

Further information

Linoleum flooring is made of linseed oil, cork dust, wood flour, pine resin and pigments, and then pressed into cotton scrim fabric.

Vinyl is a synthetic product made of polyvinyl chloride (PVC). When combined with asbestos, which acts as a binder, the product had durability and firmness for high foot-traffic areas. Also known as a thermoplastic tile, asbestos was added as to the vinyl resin during the manufacturing process. It may be incorporated as a backing on the tile, or in the main tile material itself.

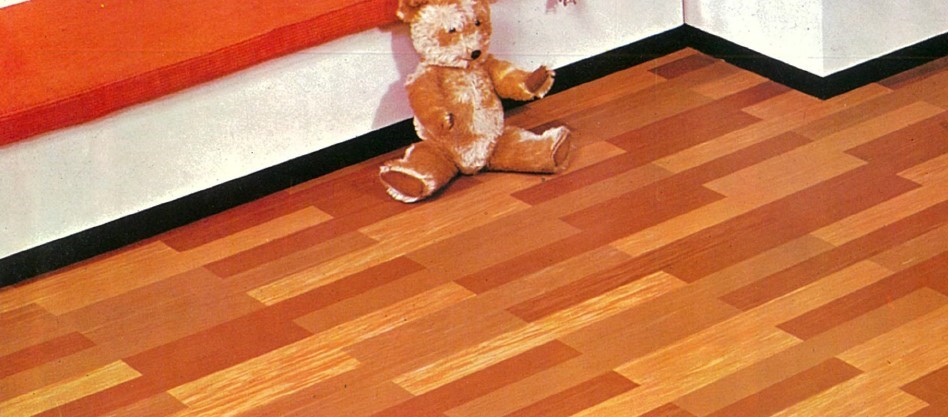

The tiles were marketed for both flooring and walls. Tiles were not only square but produced in rectangular sizes and (feature) planks and strips. As well as plain colours, tiles and flooring imitated terrazzo, marble and woodgrain. Tile and flooring manufacturers also supplied asbestos felt underlay and adhesives for use when laying.

Tiles and feature strips were marketed to be installed in pattens at the discretion of the customer, including vertically on walls and other structures.