Home / Insulation / Millboard

Millboard

Description

Lightweight and flexible insulating sheet for temperatures up to 540°C. Usually white in colour. Used as insulation (keeping heat in) and as a firewall or fire-proof lining for non-liquid fire risks.

Produced in various thicknesses and sheet sizes.

The composition of Hardie’s and Hardie-BI Company Asbestos Millboard sheets was approximately 10 to 15 per cent amosite asbestos and 15 to 20 per cent cement mixed with diatomaceous earth and other inorganic fillers.

CSR advertised a Millboard sheet consisting ‘almost entirely of chrysotile asbestos.’

Some formulations comprised 70-80% asbestos.

Brands/products

- Hardie’s

- Hardie-BI

- CSR

- Salamander

Years of production/use

First produced in the USA in the early 20th Century. Early imported product may be present in older industrial sites and homes with original structures or product requiring insulation.

Hardie’s produced this product from 1950 and co-produced it with Bradford Insulation Industries and CSR between 1964-1971.

Residential uses

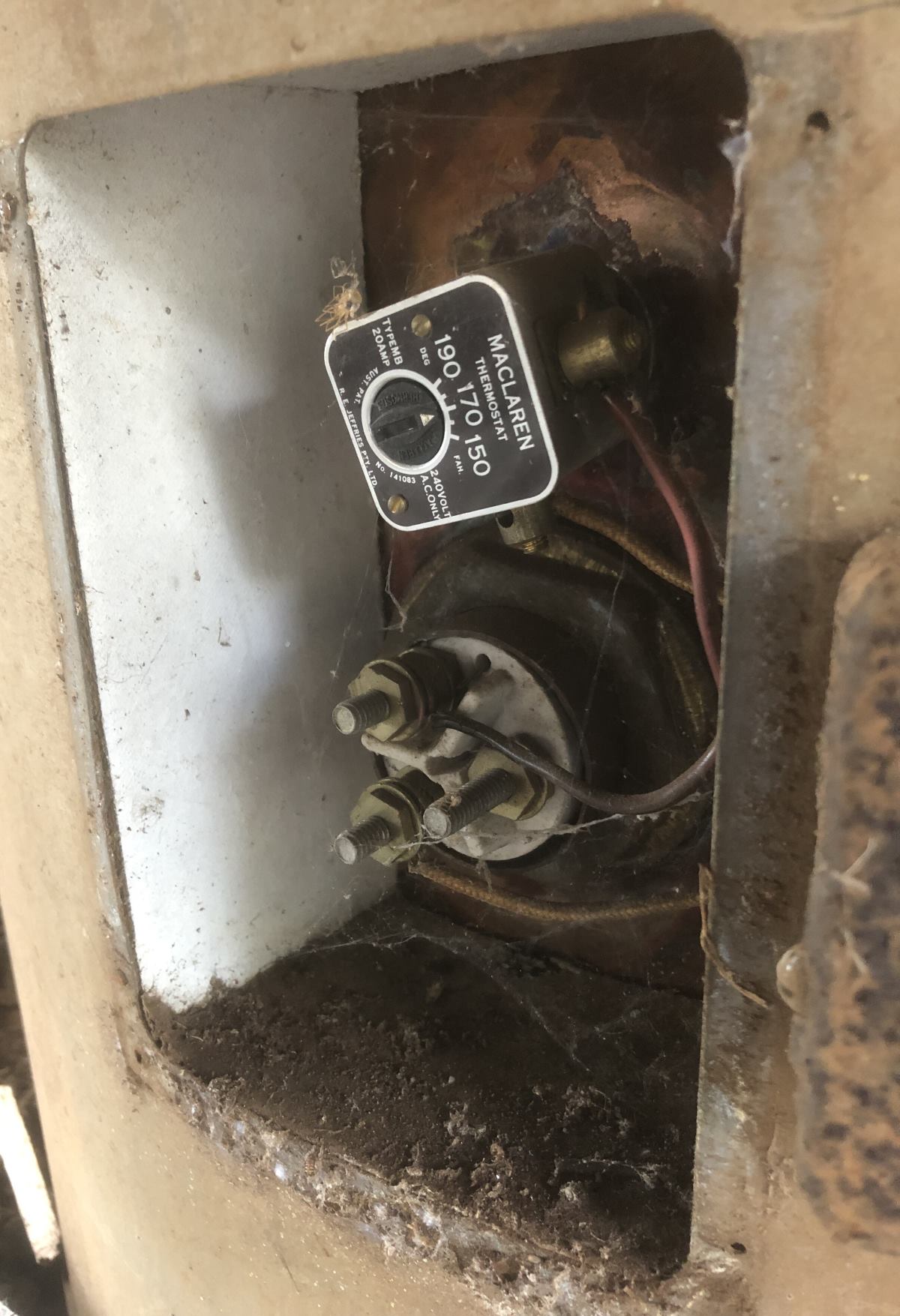

- Hot water systems and household wood burners/oil burners/stove area

- Popular for DIY ad-hoc insulation jobs

Industrial uses

- Air conditioning ducting around heat elements

- Advertised for ceilings, floors, partitions, projection boxes, elevator shafts, ovens, oil burners and furnaces

- Electrical relay box and meter box linings or behind electrical mounting boards, which also may contain asbestos

Be aware

Like other insulating materials, designed to be hand-cut to shape/size on site, which exposed fibres.