Home / Insulation / Asbestos insulating cements

Asbestos insulating cements

Description

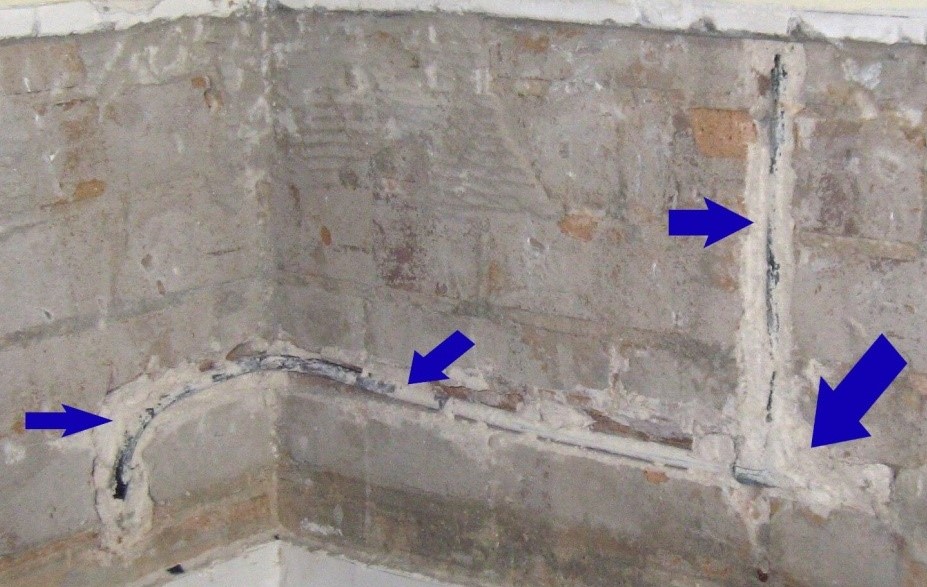

Insulating cements designed for trowel application after mixing with water to supplement blocks or pipe sections and seal joints. Also applied where blocks/sections did not suit the site, such as irregular surfaces like valves, flanges and pipe fittings.

Primary application is not as a sealant. Refer Asbestos sealants information page.

Hardie’s 85% Magnesia and High Temperature cements were manufactured with the same materials as the blocks/section products. 85% Magnesia contained 85-95% Magnesium Carbonate and 10-15% asbestos binder. Usually amosite asbestos with small amount of chrysotile asbestos.

High Temperature cement was composed of 12% amosite asbestos, 44% basic magnesium carbonate and 44% diatomaceous earth.

Brands/products

- 85% Magnesia Insulating Cement

- High Temperature Insulating Cement

- Pabco Insulating Cement

- Johns Manville (USA)

- Ruberoid (USA)

- Zonolite (USA)

Years of production/use

1930s – early 1970s

Residential uses

Used by plumbers to insulate exposed piping, particularly hot water pipes.

‘Pipe chasing’ was commonly used in older residential settings.

Industrial uses

Industrial plant, furnaces, high temp piping

Be aware

Degradation of product from exposure to high temperatures at site.