Home / Building structures & components / Roofing / Asbestos cement slate and shingles

Asbestos cement slate and shingles

Description

Moulded AC used as roof tiling (slates and shingles), on gable ends and exterior cladding. Around 4mm thickness.

Later production of shingles was often sheets of numerous tile appearance. Usually around four tiles each sheet. The Shingleplank product was manufactured in red and pinewood colours with a woodgrain texture.

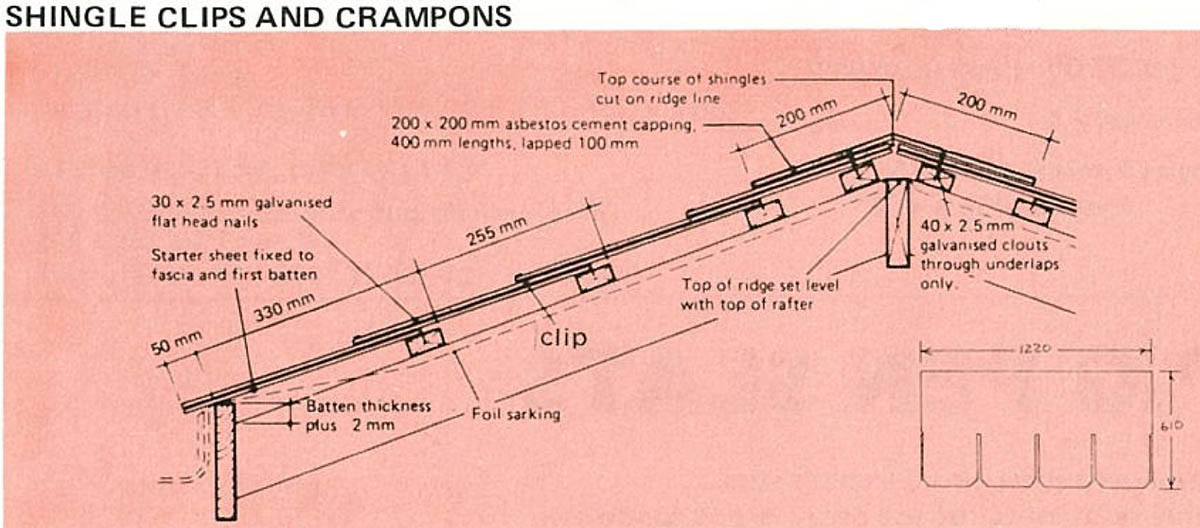

Overlapped and nailed to roof battens with crampons dividing sheets. May be laid on a layer of asbestos containing felt or tar paper. For larger roofs, such as churches, individual copper sheets may have been used underneath each slate.

AC ridge capping also used. Federation and Queen Anne era housing often incorporated decorative terracotta ridge designs. Wunderlich produced and supplied terracotta roofing products along with AC slates.

Replacement of original slates with AC slates during the mid 20th Century preserved the original appearance. Slate and shingle combinations were used: decorative on larger roofs or slates on the main roof and shingles on smaller bay roofs and under bay windows.

Some produced in a range of colours: natural (AC), light grey, brown, charcoal grey. Fibrolite marketing from 1920s has colour range as …pleasing shades of red, russet, blue-black and light grey.

Shingles were produced in rectangular and curved (half- moon) shapes.

Older shingles and ‘slates’ may have the same weathered surface appearance as AC sheeting. In the southern states, organic growth on the southern or sheltered side of the structure is common with older tiles of these types.

Mainly produced with chrysotile asbestos. Hardies were supplied with crocidolite (blue) asbestos by CSR between the mid 1950s to 1968. Crocidolite asbestos tended to have stronger fibres and so mixing it in with chrysotile provided greater structural strength to an AC product like slates/shingles which were a thinner finished material than sheeting.

Brands/products

- Tasbestos

- Fibrolite

- Hardie’s Multi-notched shingles or Shingleplank

- Durabestos

- Endurite

- The Asbestos Slate & Sheet Manufacturing Co Ltd (original manufacturer of Hardies Fibrolite – early 20th Century)

Years of production/use

Late 1800s to 1980s. Stocks up to around 1920 were likely imported.

Following the cease of asbestos use, Hardie’s manufactured a near identical cellulose fibre product to Shingleplank under the name Hardie’s Roofing Shingles II. This may be branded on the underside edging. If unsure, sampling for testing by a NATA accredited laboratory is the only method of confirming the non-asbestos product.

Residential/industrial uses

- Housing and early 20th Century government buildings. In latter half of 20th Century more commonly restricted to residential houses as application was a more expensive process to that of sheeting

- AC slates were a cheaper alternative for replacement of real slates or wooden shingles on Church roofs originally constructed in 1800s, and retaining a similar appearance.

- James Hardie (Fibrolite) marketing from the late 1920s states:

FIBROLITE Slates are used by Government Departments throughout the Commonwealth. The NSW Railways and Tramways Department, who first tested our slates over 23 years ago, now use large quantities of Fibrolite Slates for roofing station platforms, Engine sheds, signal boxes etc. The NSW Education Department and other Government Departments use large quantities of Fibrolite slates for roofing.

Be aware

Roof guttering and pipework will likely accumulate asbestos debris and dust.

Product manufactured between the mid 1950s to 1968 might contain crocidolite.